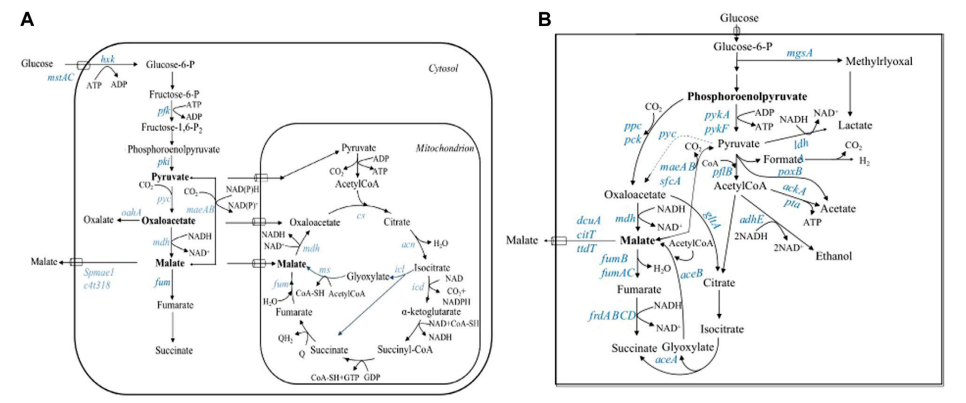

Glucosamine (GlcN) and N-acetylglucosamine (GlcNAc) are important precursor substances for the synthesis of glycosaminoglycans, with extensive application value in many fields. Microbial fermentation has many advantages in the production of GlcN and GlcNAc, and is increasingly favored. This study constructed genetically engineered strains of Escherichia coli with high production of GlcN and GlcNAc, laying the foundation for industrial production.

Background: Glucosamine (GlcN) and its derivatives N-acetylglucosamine (GlcNAc) are important precursors for the synthesis of glycosaminoglycans, with extensive application value in the fields of medicine, cosmetics, and health products. Traditional production methods have many drawbacks, such as environmental pollution, limited raw materials, and are not suitable for people who are prone to seafood allergies. Therefore, the use of microbial fermentation to produce GlcN and GlcNAc is becoming increasingly popular.

【 Objective 】 To utilize microbial fermentation to produce and increase the yield of N-acetylglucosamine, and explore molecular modification and fermentation condition optimization strategies.

【 Method 】 Using Escherichia coli MG1655 as the starting strain, the expression vector was first used to co express glmS derived from Escherichia coli and gna1 derived from brewing yeast to construct a biosynthetic pathway for GlcNAc. Then, CRISPR/Cas9 technology was used to knock out the metabolic and transport pathways of GlcNAc to increase its production. Finally, fermentation conditions were optimized to further increase the production of GlcNAc.

CRISPR Tools Products

| Category | Subcategory | Product Name | Catalog Number | Price |

|---|---|---|---|---|

| Genome Editing | CRISPR Tools | Cas9-NLS | GE0001 | Online Inquiry |

| Genome Editing | CRISPR Tools | CD® Cas12a | GE0002 | Online Inquiry |

| Genome Editing | CRISPR Tools | CD® Cas9 Nickase | GE0003 | Online Inquiry |

| Genome Editing | CRISPR Tools | CD® Cas9 Nuclease | GE0004 | Online Inquiry |

| Genome Editing | CRISPR Tools | CRISPR Nuclease mRNA | GE0005 | Online Inquiry |

| Genome Editing | CRISPR Tools | gRNA Synthesis Kit | GE0006 | Online Inquiry |

| Genome Editing | CRISPR Tools | Monarch RNA Cleanup Kit | GE0007 | Online Inquiry |

| Genome Editing | CRISPR Tools | sgRNA Synthesis Kit | GE0008 | Online Inquiry |

| Genome Editing | CRISPR Tools | SNAP-tagged dCas9 | GE0009 | Online Inquiry |

| Genome Editing | CRISPR Tools | Staphylococcus aureus Cas9 | GE0010 | Online Inquiry |

| Genome Editing | Gene Assembly | High-Fidelity DNA Assembly Master Mix | GE0012 | Online Inquiry |

| Genome Editing | Genome Editing Detection Tools | Genomic Cleavage Detection Kit | GE0013 | Online Inquiry |

【 Result 】 A GlcNAc producing strain RY-5 was obtained through molecular modification. After 20 hours of fermentation, the production of GlcNAc reached 2.36 g/L, which was 29 times higher than the initially constructed strain RY-1. Further fermentation optimization was carried out on conditions such as liquid volume and the addition time of inducer IPTG. The production of GlcNAc reached 7.74 g/L, which was 2.3 times higher than before optimization.

Enzyme Kits Products

| Category | Subcategory | Product Name | Catalog Number | Price |

|---|---|---|---|---|

| Enzyme Kits for Nutrients and Metabolites | Enzymatic Activity Assay Kits | Lysozyme Activity Kit | EK0113 | Online Inquiry |

| Biosynthesis Chemicals | Carbohydrate derivatives | Uridine 5’-Diphospho-N-acetylglucosamine Disodium Salt | BC-10325 | Online Inquiry |

【 Conclusion 】 A recombinant E. coli engineering strain was successfully constructed to produce GlcN and GlcNAc, laying the foundation for the industrial production of microbial synthesis of GlcN and GlcNAc.

Figure 1 Metabolic Process of GlcN and GlcNAc in Recombinant Escherichia coli

Figure 2 Flow chart of continuous genome editing using a dual plasmid system

Figure 3. Colony PCR validation of plasmid pTrcHisA glmS gna1 M: DNA Marker 1-6: Different monoclonal colonies of engineering strain RY-1

Figure 4 Comparison of growth and GlcN and GlcNAc production of engineering strains RY-1 and Escherichia coli MG1655 A: Comparison of growth between control strains and RY-1 B: The GlcN production of the control strain and RY-1 C: GlcNAc production of control strain and RY-1. *: P<0.05

Figure 5 Knockout validation of nagB (A) and nagA (B)

Figure 6 Comparison of GlcN and GlcNAc production between strains RY-3 and RY-1 A: Comparison of growth between RY-3 and RY-1 B: Comparison of GlcN production between RY-3 and RY-1 C: Comparison of GlcNAc production between RY-3 and RY-1. *: P<0.05

Figure 7 Knockout verification of manXYZ and nagE

The verification of the manXYZ and nagE knockout M: DNA Marker; 1, 3, 5, and 7: Escherichia coli MG1655 strain PCR with different validation primers; 2: Escherichia coli MG1655 Δ NagB Δ NagA Δ ManX strain; 4: Escherichia coli MG1655 Δ NagB Δ NagA Δ ManXY strain; 6: Escherichia coli MG1655 Δ NagB Δ NagA Δ ManXYZ strain; 8: Escherichia coli MG1655 Δ NagB Δ NagA Δ ManXYZ Δ NagE (RY-4)

Figure 8 Comparison of fermentation conditions between ManXYZ and nagE gene knockout strains RY-5 and RY-3 A: Comparison of growth conditions between RY-5 and RY-3 B: Comparison of GlcN production between RY-5 and RY-3 C: Comparison of GlcNAc production between RY-5 and RY-3

Figure 9 GlcNAc production and comparison of capacity in fertilization of genetically engineered strain RY-5 A: GlcNAc production in genetically engineered strain RY-5 B: Comparison of the growth of RY-5 with different capacities C: Comparison of GlcNAc production of RY-5 with different capacities. * *: P<0.01

Figure 10 Effects of the IPTG adding time in the genetically engineered strain RY-5 A: The concentration of RY-5 at different IPTG adding times B: IPTG addition time responses to the growth of RY-5 at the end of consideration C: GlcNAc production of RY-5 at different IPTG adding times