L-maleic acid is a four carbon dicarboxylic acid found in food, chemical and pharmaceutical industries. L-malic acid is an intermediate in the tricarboxylic acid cycle (TCA), one of the 12 most promising biobased platform chemicals – according to the US Department of Energy. Yet industrial production today mainly depends on chemical production of petrochemical raw materials and suffers from a double problem of resource and environmental degradation. So microbial fermentation-based production of L-malic acid gained broad popularity.

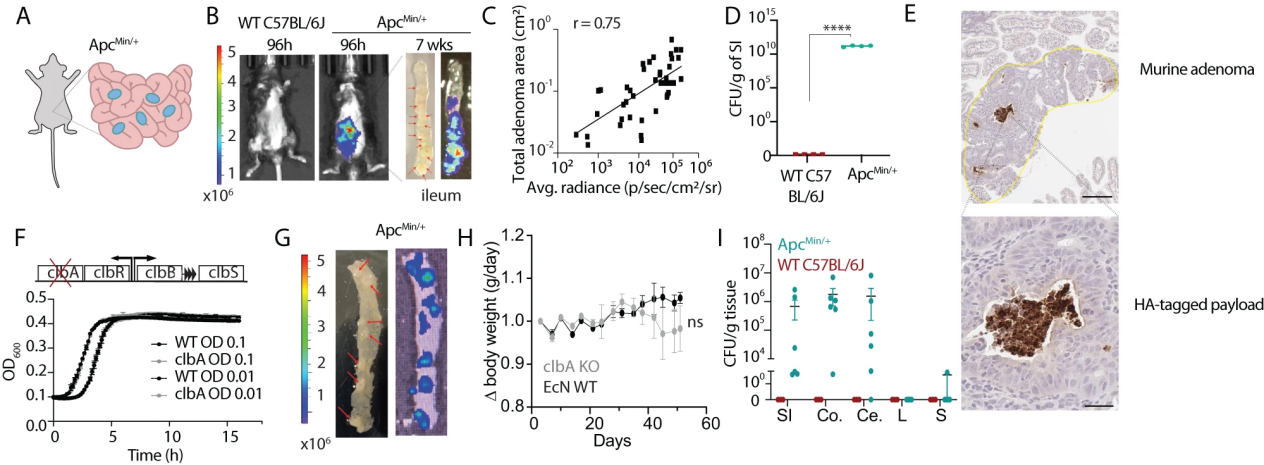

Biosynthetic pathways of L-malic acid in eukaryotes(Z Wei, et al., 2021)

Microbial methods for malic acid production

Fermentation by microbes is now a promising field of research to produce L-malic acid in a sustainable manner. It was discovered that the malic acid produced by many different microorganisms such as fungi, yeasts and bacteria could be made naturally or through modified metabolic mechanisms. For example:

Wild-type microbes: like Aspergillus spp. and Penicillium spp. etc, has been used to synthesize malic acid from carbon (like glucose) and some strains can generate yields of over 100 g/L under ideal conditions.

Mutant and laboratory-adapted strains: The strains developed by physical or chemical mutagenesis plus screeners were better acid-producing (using corn straw hydrolysate to obtain a malic acid yield over 120 g/L, for example).

Mutations in genetic strains: Metabolic engineering focuses on modifying major enzymes or transport pathways to optimize the flow of metabolism and dramatically boost the production of malate. For instance, 201 g/L of malate were produced by rebuilding the shortened TCA pathway.

Key strategies for metabolic engineering

The literature lists several metabolic engineering approaches, such as:

Stimulate the synthetic pathway: Increase the production of malate through increasing the activity of enzymes involved in the reduced TCA pathway (pyruvate carboxylase and malate dehydrogenase).

Better transport: Defining malate transporters (Schizosoma’s SpMae1 being a prime example) overexpression boosts malate efflux efficiency.

Elimination of by-products: Eliminate the amount of by-products (succinic acid and citric acid) through the suppression of metabolic pathways related to them thereby increasing yield of target products.

Optimise carbon sources: Introduce heterologous genes to expand substrate selection, and make malic acid with renewable sources like glycerol and cellulose.

Industrial prospect

Even though lab-scale biological production of malic acid has been made with great success, the following problems remain for industrial production:

- Maximise the economics of the fermentation process (by changing the mix of the medium and conditions of fermentation).

- Build more effective strains and continuous fermentation.

- Make malic acid purification process better so that production is less expensive.

Outlook

Future research directions include:

- Comprehensive application of multi-omics technology for systematic study of metabolic networks for strain design.

- Develop an intelligent fermentation control system to constantly adjust the main metabolic pathways to yield stable highs.

- Strengthen green process research and development and encourage biobased malic acid applications in biodegradable plastics, pharmaceutical intermediates and more.

As the technology of microbial fermentation continues to improve, biomanufacturing L-malic acid will not only supersede the traditional petrochemical route to synthesis but also be highly complementary to the sustainable chemical production model.

Reference:

Z Wei, Y Xu, Q Xu, W Cao, H Huang… – Frontiers in Bioengineering …, 2021 – frontiersin.org