A synthetic P. putida consortium for simultaneous TPA and EG degradation.

In response to the astonishing growth of global plastic pollution, researchers have developed a synthetic microbial ecosystem that can collectively upgrade plastics to the required chemicals. Researchers did not attempt to synthesize a single organism that could complete all the upgrading and recycling steps, but instead utilized two types of bacteria to effectively degrade one of the most common plastics – polyethylene terephthalate (PET) – into a non-toxic, environmentally friendly, and biodegradable polymer.

This research paper titled “Engineering Microbial Division of Plastic Upgraded Recycling” was published in Nature Communications by Dr. Ting Lu, a professor of bioengineering at the University of Illinois, Urbana Champaign, and Dr. James J. Collins, a professor of medical engineering and science at the Massachusetts Institute of Technology, along with colleagues.

Two is better than one

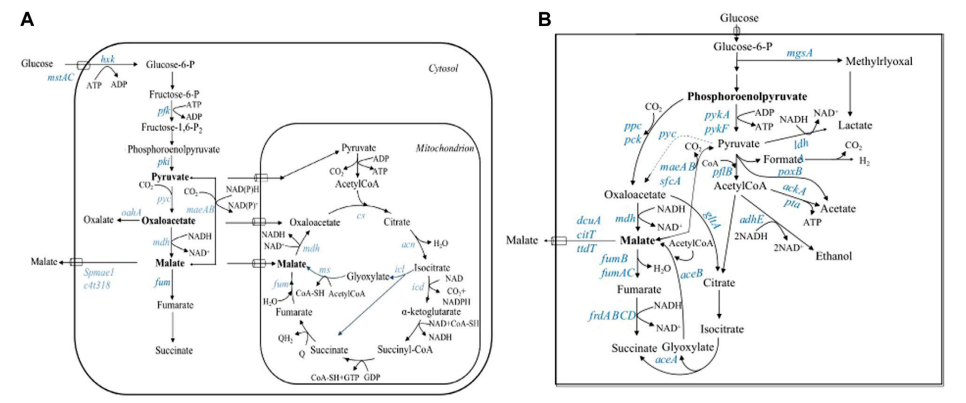

The use of microorganisms for bioconversion is rapidly becoming a viable alternative to traditional polymer upgrading and recycling methods, as it has the potential to simplify production processes and combine waste degradation with product generation. For example, various microbial isolates have been discovered and used for the decomposition and absorption of PET. There are also modified bacterial and fungal strains that can accelerate the hydrolysis of PET and convert plastic waste into useful chemicals and products.

Despite these promising developments, the complexity of polymer upgrading and recycling poses several challenges for current biotransformation methods that focus on single culture.

The co authors of this paper, Bao Teng, Qian Yuanchao, and Xin Yongping, improved the degradation of PET by Pseudomonas putida on two types of soil bacteria. Each strain is only responsible for treating one of the two compounds produced by the decomposition of chemical plastics: terephthalic acid or ethylene glycol. When used in series instead of using a single strain for two products, these strains increase productivity. Then, the bacteria upgraded the plastic to biodegradable polymer medium chain long polyhydroxyalkanoates (mcl PHA) and polyurethane and adipic acid precursor cis cis cis myxoates (MA). Polyurethane is used for insulators, foam, coatings and adhesives, and nylon is made of adipic acid.

This design upgrade recycling consortium can be used to manufacture more chemicals besides mcl-PHA and muconate. They can achieve this goal by adding new biosynthetic pathways and utilizing their modular structure to connect them to the main metabolic nodes of TPA and EG catabolism. In addition, although this study is limited to the upgrading and recycling of PET, its potential concepts and strategies may be applicable to the treatment of other types of plastics, thus providing insights for the development of sustainable bioeconomy.

Recommended Services and Products

|

Structure Engineering for BiopolymerEnhance your biopolymer research with cutting-edge structure engineering services and products from BioSynsis. Learn more about how you can optimize biopolymer production and applications. |