Enzyme Active Site Engineering is an intriguing and critical scientific field. It involves modifying enzymes to alter their activity. By carefully changing an enzyme's active site, we can significantly enhance its performance and specificity. This improvement allows for more efficient and environmentally friendly processes, making it a valuable tool for sustainable industrial processes. It is particularly important for industries such as pharmaceuticals, agriculture, and biofuels. This field holds potential to revolutionize these sectors by offering efficient, cost-effective, and eco-friendly solutions.

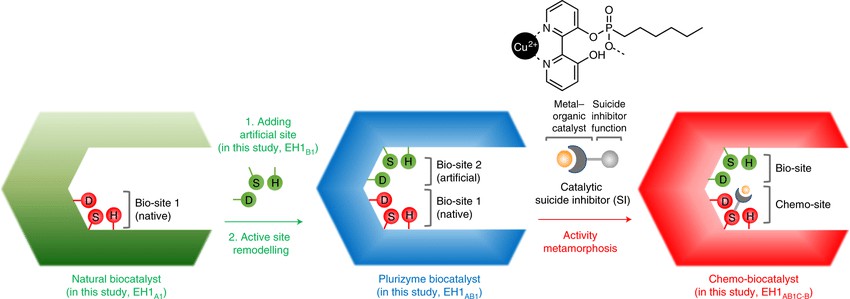

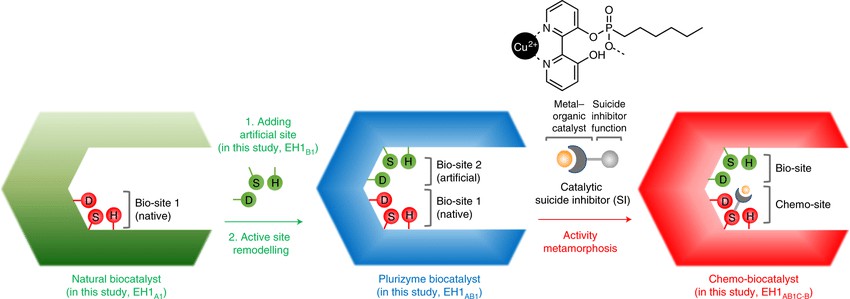

General concept for engineering proteins with two active sites (Sandra A. R., et al., 2020)

General concept for engineering proteins with two active sites (Sandra A. R., et al., 2020)

Technical Route

Our method for enzyme active site engineering, designed to enhance the performance and specificity of enzymes for use in a variety of industrial processes, is a comprehensive, multi-step process:

| Steps |

Objective |

Description |

| Bioinformatics Employment |

Identify enzymes for modification |

Employ bioinformatics to accurately identify the enzymes requiring modification. This step sets the foundation for subsequent modifications by pinpointing the enzymes with potential for improvement. |

| Enzyme Understanding |

Understand current enzyme function |

Dedicate time to comprehensively analyze the structure and function of identified enzymes. Gain insights into their current function and potential for modification, identifying key areas for alteration. |

| Molecular Dynamics Simulations |

Predict enzyme behavior post-modification |

Utilize molecular dynamics simulations to predict how enzymes will behave post-modification. Gain valuable insights into potential outcomes, guiding the subsequent modification process based on predicted behavior. |

| Site-Directed Mutagenesis |

Deliberate changes to DNA sequences |

Perform site-directed mutagenesis to make targeted changes to DNA sequences encoding for enzymes. Alter the amino acid sequence at the enzyme's active site, paving the way for desired alterations in enzyme activity. |

| Enzyme Alteration |

Achieve desired enzyme activity |

Implement changes in the DNA sequence resulting in desired alterations in enzyme activity. This step integrates meticulous planning and detailed work to create a newly functioning enzyme tailored to specific requirements. |

| High-Throughput Screening |

Verify modification success |

Confirm successful modifications and intended enzyme function through high-throughput screening. Conduct numerous tests efficiently to ensure the enzyme operates as expected post-modification, validating the effectiveness of the alterations. |

Service Process

Our service process for enzyme active site engineering is an in-depth and meticulous 5-step process:

1. Consultation and Planning: We assess your needs, objectives, and constraints. Then, we plan the project, outlining timelines, resources, and expected outcomes.

2. Enzyme Identification and Prediction: Using advanced bioinformatics tools, we identify the enzyme for modification and predict its activity post-modification.

3. Mutagenesis and Modification: We modify the DNA sequences, changing the enzyme's active site amino acid sequence to achieve the desired enzyme alteration.

4. Verification and Optimization: We verify the activity of the modified enzyme to ensure success and the desired effect, and then optimize it for improved performance.

5. Report and Follow-up: We provide a comprehensive report detailing the work, results, and future recommendations. Our follow-up services ensure everything is functioning as expected and to your satisfaction.

We're here to assist you. If you have any questions, need more information, or would like to discuss a potential project, please don't hesitate to contact us. Our team is always eager to help and share our expertise.

Applications

| Application |

Description |

| Pharmaceutical Industry |

Enzyme Active Site Engineering finds extensive application in the pharmaceutical industry. It plays a crucial role in drug discovery and development, where customized enzymes are designed to catalyze specific reactions, aiding in the synthesis of pharmaceutical compounds. |

| Biotechnology |

Enzyme Active Site Engineering is widely utilized in biotechnology for various purposes such as biocatalysis, biofuel production, and bioremediation. By modifying enzyme active sites, tailored enzymes can be created to optimize industrial processes, enhance efficiency, and reduce environmental impact. |

| Food Industry |

Enzyme Active Site Engineering is applied in the food industry to improve food processing and production. Customized enzymes can be engineered to enhance flavor, texture, nutritional value, and shelf life of food products. They are also used in processes such as brewing, baking, and dairy production. |

| Environmental Remediation |

Enzyme Active Site Engineering contributes to environmental remediation efforts by developing enzymes capable of breaking down pollutants and toxins. These engineered enzymes can efficiently degrade pollutants in soil, water, and air, offering sustainable solutions for environmental cleanup and protection. |

| Agricultural Biotechnology |

Enzyme Active Site Engineering plays a role in agricultural biotechnology by creating enzymes that optimize crop yield, nutrient uptake, and resistance to pests and diseases. Engineered enzymes can enhance the efficiency of agricultural processes such as fertilization, pest control, and plant metabolism. |

Case Study

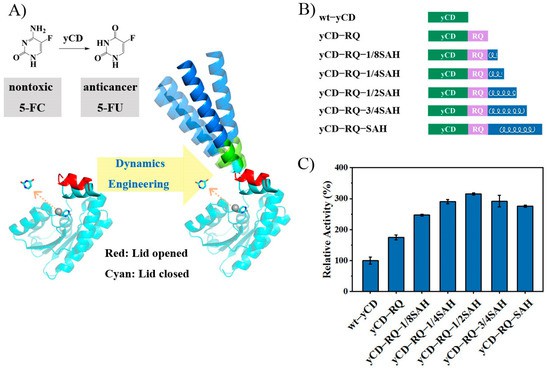

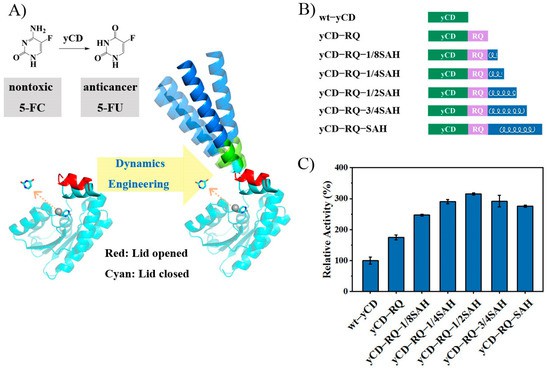

Engineering the active site lid dynamics to improve the catalytic efficiency of yeast cytosine deaminase (yCD). The figure illustrates constructs of yCD variants and their relative activity. (A) Schematic drawing of the strategy to accelerate the yCD catalysis (5-FC to 5-FU) by engineering the dynamics of the C-terminal helix (which controls the rate-limiting product release) through the helix extension with a single α-helix SAH. The dynamics of SAH may enhance the dynamics of the C-terminal helix. (B) yCD constructs with the SAH helix (or its part) and a linker RQ (composed of five residues) in between. (C) Relative catalytic activity against 5-FC, with the wt-yCD activity set to 100%. The reaction mixture contained 10 mM 5-FC and 0.05 μM yCD in a buffer of 20 mM Tris and 100 mM NaCl, pH 7.0. The reactions were carried out at 303 K in triplicate.

Constructs of yCD variants and their relative activity (Hanzhong D., et al., 2023)

Constructs of yCD variants and their relative activity (Hanzhong D., et al., 2023)

FAQs

In this section, we have compiled some commonly asked questions about Enzyme Active Site Engineering. These questions and their corresponding answers provide a comprehensive understanding of the concept. If you don't find the answer you're looking for, feel free to reach out to us.

Q: What industries can benefit from enzyme active site engineering?

A: Industries such as pharmaceuticals, agriculture, biofuels, and more can benefit from enzyme active site engineering.

Q: What is the purpose of high-throughput screening in this process?

A: High-throughput screening is used for enzyme activity verification to ensure that the modifications have been successful, and the enzyme is functioning as anticipated.

Q: How long does the enzyme active site engineering process take?

A: The duration of the process can vary depending on the complexity of the enzyme and the extent of modifications required.

Q: What are the potential risks or challenges in enzyme active site engineering?

A: Some challenges include ensuring precise modifications and predicting enzyme behavior accurately. However, our advanced computational methods and meticulous process help to mitigate these risks.

Q: Can the enzyme activity be controlled or reversed once modified?

A: The modifications are typically permanent, but the level of activity can often be controlled by varying the conditions under which the enzyme is used.

Q: What are the environmental benefits of enzyme active site engineering?

A: By improving enzyme efficiency, we can develop processes that require less energy and produce fewer waste products, contributing to more sustainable industrial practices.

Q: Is enzyme active site engineering applicable in the food industry?

A: Yes, enzyme engineering can be used to improve the production processes in the food industry, such as in brewing, baking, and cheese-making.

Q: Can the modifications affect the enzyme's stability?

A: Depending on the modification, there could be changes to the enzyme's stability. However, our process includes steps to verify and optimize the enzyme's performance post-modification.

Q: Are there ethical considerations in enzyme active site engineering?

A: As with any biotechnology, ethical considerations should be taken into account. However, our work strictly adheres to all relevant guidelines and regulations to ensure ethical and responsible practices.

General concept for engineering proteins with two active sites (Sandra A. R., et al., 2020)

General concept for engineering proteins with two active sites (Sandra A. R., et al., 2020) Constructs of yCD variants and their relative activity (Hanzhong D., et al., 2023)

Constructs of yCD variants and their relative activity (Hanzhong D., et al., 2023)