Welcome to our advanced enzyme AI design platform - EnzymoGenius™, which serves food and beverage processing research. We offer a range of amylase-based solutions that can be applied at all key stages of carbohydrate processing research, working to improve the efficiency and quality of carbohydrate processing.

Role of Amylase in Carbohydrate Processing

Starch, a pivotal carbohydrate, is a crucial industrial raw material. It is not only widely consumed directly but also serves as the foundation for various deep-processing starch products. Numerous enzymes are indispensable for starch processing, with amylase playing a fundamental role in ensuring the efficient utilization of starch.

Amylase, a prevalent hydrolyzing enzyme, represents one of the largest categories. In contemporary starch processing, enzymatic approaches have superseded chemical methods. This shift facilitates the hydrolysis of starch, yielding amino acids, organic acids, alcohols, antibiotics, and sweeteners. Amylase finds predominant utility in two key processes within the realm of starch processing:

- Liquefaction: Hydrolysis of α-1,4-glycosidic bonds using α-amylase to generate oligosaccharides, rapidly reducing the starch solution's viscosity.

- Saccharification: Utilizing β-amylase to hydrolyze α-1,4-glucan molecules to generate small molecule sugars such as glucose, maltose, and ultimate dextrin.

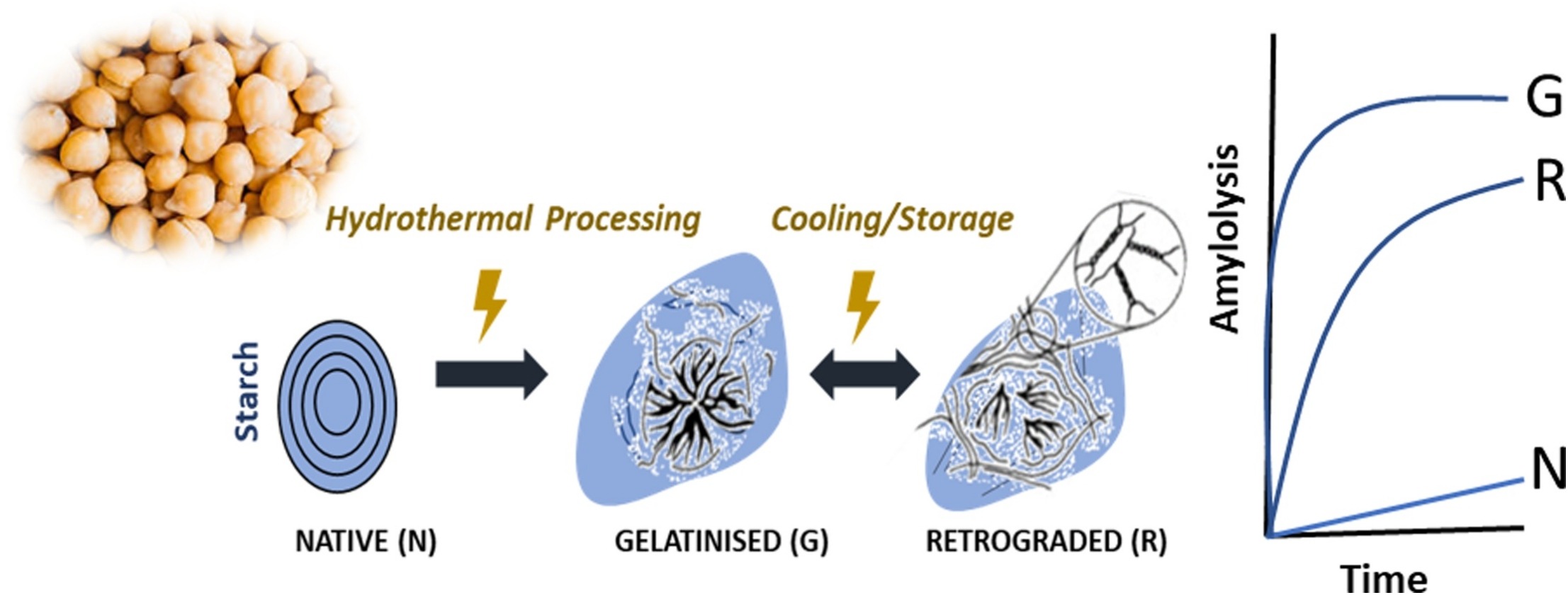

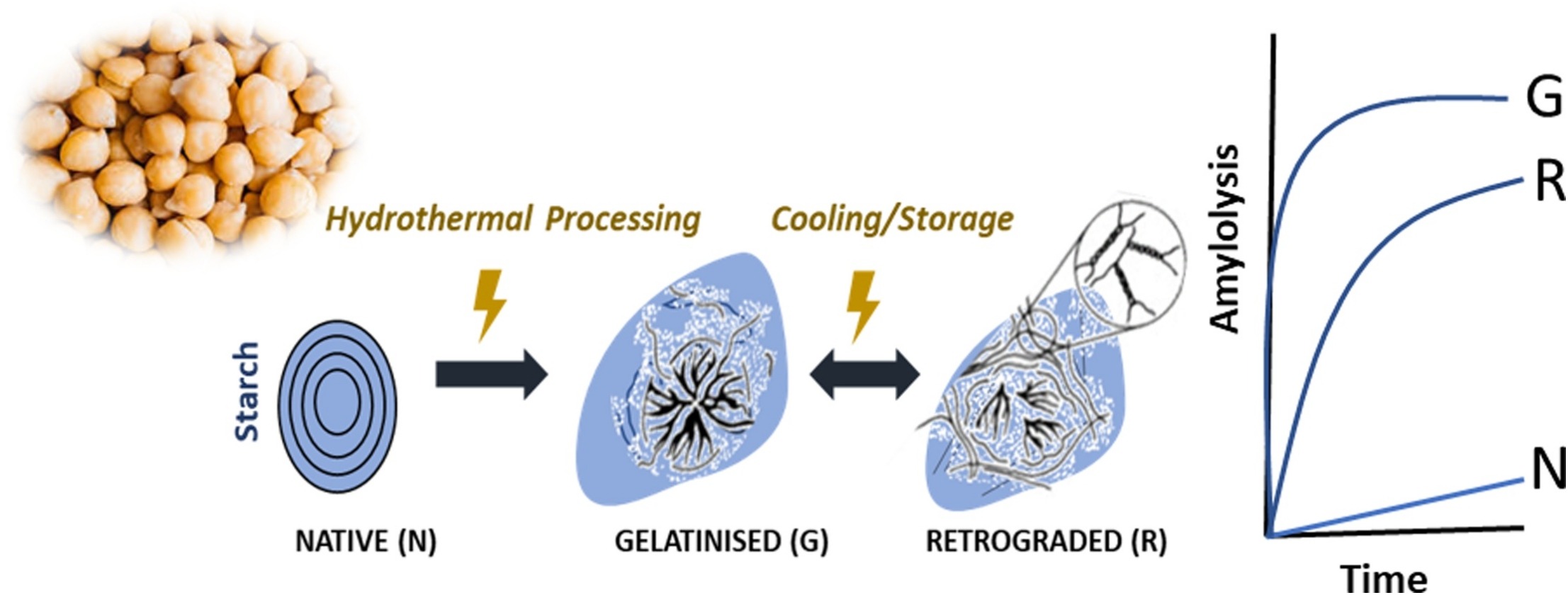

Fig. 1 Hydrolysis of chickpea starch by α-amylase under different treatment conditions. (Cathrina H, et al., 2021)

Fig. 1 Hydrolysis of chickpea starch by α-amylase under different treatment conditions. (Cathrina H, et al., 2021)

In addition, amylase activity is essential for promoting glucose absorption, which cleaves the glycosidic bonds in starch molecules and breaks down complex starch molecules into intermediates such as dextrins, maltose, maltotriose, etc., which are then broken down into glucose by other enzymes, such as maltase and isomaltase, to promote the effective absorption of nutrients, which is the main source of energy for a variety of cellular functions.

Current Research Trends in Amylases

- Use of genetic engineering and enzyme immobilization techniques to improve amylase stability and catalytic efficiency.

- Research on the application of amylases in starch liquefaction, saccharification, and fermentation processes to enhance bioethanol production and other bio-based products.

Products and Solutions Offering

High-quality Amylase

Our deliverable amylases have excellent starch substrate specificity and affinity, temperature resistance, pH tolerance, and stability to ensure efficient catalytic reactions while being compatible with various processing environments and maintaining high activity during long-term storage.

Custom Amylase-based Solutions

- Improving The Pretreatment Process: Customized solutions for the pretreatment of starch raw materials, breaking down starch molecules into simpler forms for subsequent processing.

- Saccharification: Customized solutions facilitate the conversion of starch to sugar, an important step in applications such as brewing and other food processing production.

- Fermentation: Facilitates the conversion of sugars from starch to alcohol to assist in the fermentation process, which is important in brewing.

Services Process for Amylase Design and Optimization

1. Problem Assessment: We begin by identifying specific processing challenges and goals.

2. Data Collection: Comprehensive data on enzyme performance and the processing environment is gathered.

3. AI Modeling: Advanced algorithms and AI models are employed to design an optimized amylase.

4. Virtual Testing: The designed amylase is rigorously tested in silico to predict its performance.

5. Enzyme Synthesis: Successful designs are synthesized for practical testing.

6. Experimental Validation: In real-world conditions, the amylase's effectiveness is assessed.

7. Iterative Improvement: Based on results, the amylase is fine-tuned for enhanced performance.

Technical Advantages

- Cutting-edge Artificial Intelligence (AI): Advanced AI models for enzyme design and optimization.

- Advanced Molecular Biology Techniques: Including gene synthesis and cloning for enzyme production.

- Bioinformatics: Data analysis and interpretation for enzyme performance.

- Analytical Chemistry Techniques: Mass spectrometry and chromatography for enzyme characterization and food product analysis.

- High-Throughput Screening Tools: Rapid testing of enzyme variants to identify optimal candidates.

With a dedicated scientific team and a focus on precision and innovation, CD Biosynsis has been providing a wide range of AI-driven enzyme-based solutions, exquisitely customized to harmonize with your unique requirements. Our profound expertise extends across food baking, brewing, dairy processing, vegetable and fruit processing, value-added by-products, and food ingredient development, among others. By leveraging the synergy of AI and synthetic biology, we provide unparalleled advantages, enhancing productivity and product quality. If you are interested in the exclusive customized services for enzymes, please feel free to contact us.

Reference

- Cathrina, H.; et al. α-Amylase action on starch in chickpea flour following hydrothermal processing and different drying, cooling and storage conditions. Carbohydrate Polymers. 2021, 259: 117738.

Fig. 1 Hydrolysis of chickpea starch by α-amylase under different treatment conditions. (Cathrina H, et al., 2021)

Fig. 1 Hydrolysis of chickpea starch by α-amylase under different treatment conditions. (Cathrina H, et al., 2021)