Our advanced AI-driven enzyme design platform, EnzymoGenius™ specializes in providing advanced antibiotic-free fermentation additives solutions tailored for the saccharification and fermentation processes of lignocellulosic biomass. These solutions are designed exclusively for scientific applications, offering state-of-the-art products and innovative scientific support to enhance bioconversion processes efficiently.

Background

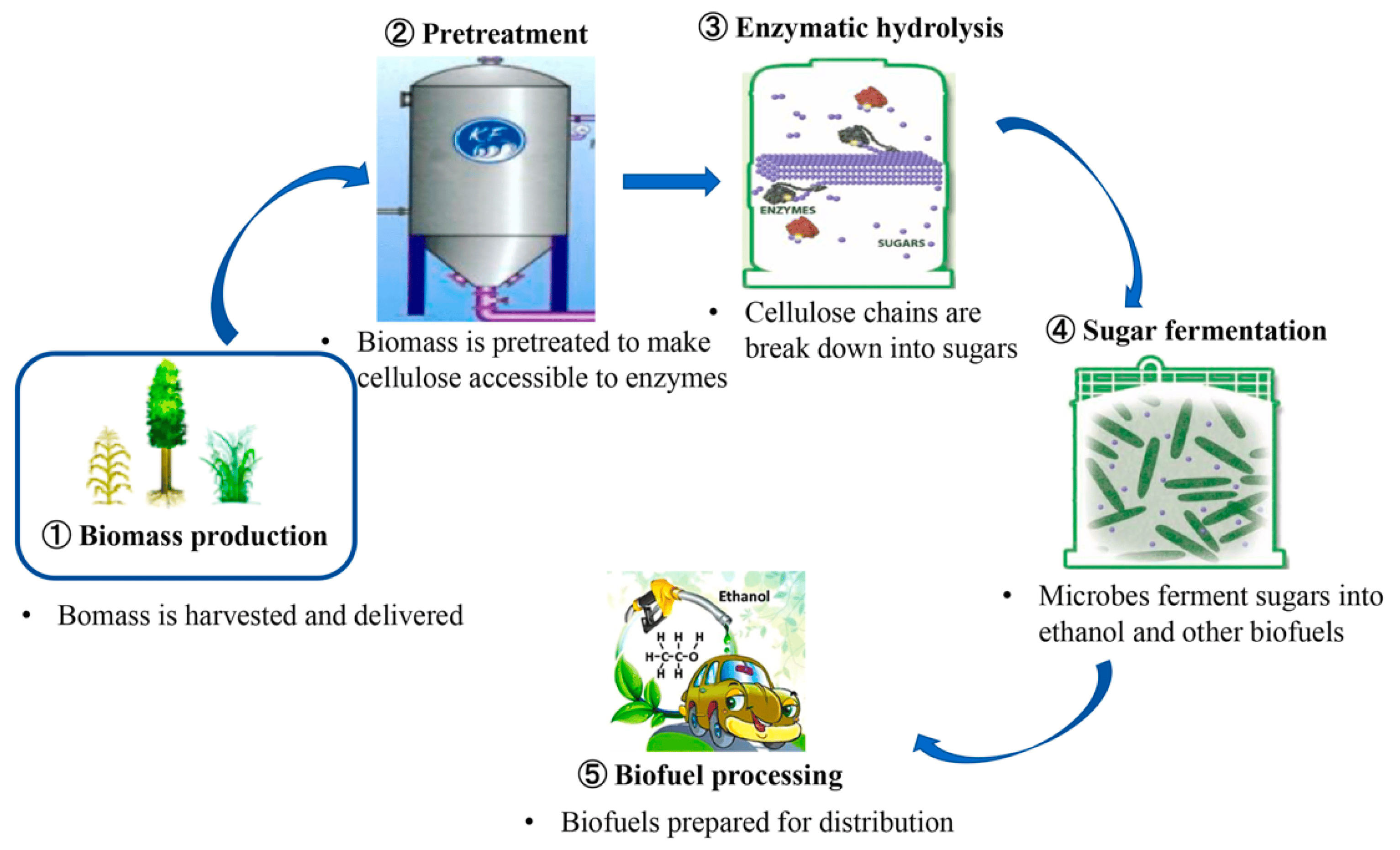

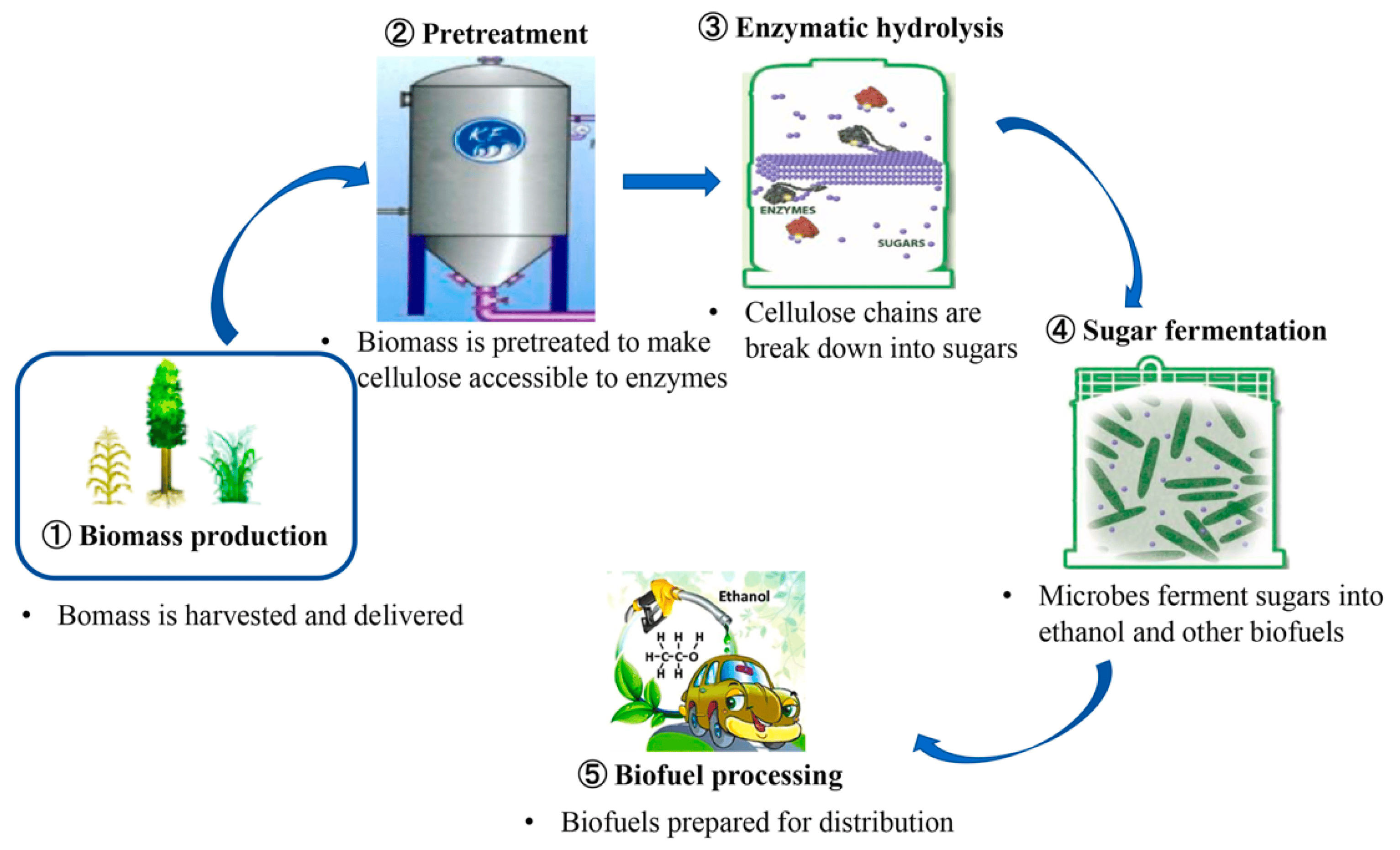

The pivotal role of antibiotic-free fermentation additives in the saccharification and fermentation of lignocellulosic biomass has gained substantial recognition in the realm of biofuel production. Lignocellulosic biomass constituted primarily of cellulose, hemicellulose, and lignin, can be transformed into fermentable sugars via enzymatic saccharification. Antibiotic-free fermentation additives are introduced in this process as they mitigate unwanted microbial contamination, particularly during the fermentation process, yet, unlike conventional antibiotic additives, they evade potential antibiotic-resistance issues. Moreover, the usage of such antibiotic-free additives promotes a more ecologically sustainable process, aligning with the objective of optimizing green technology applications. It's noteworthy that these additives provide a more reliable fermentation process by promoting robust enzymatic activity irrespective of any unpredictable changes in the fermentation environment, thereby boosting efficiency.

Fig 1. Bioconversion of lignocellulosic biomass to biofuels. (Huang C, et al., 2022)

Fig 1. Bioconversion of lignocellulosic biomass to biofuels. (Huang C, et al., 2022)

Solutions and Products Offering

High-quality Products

- Enzymatic Additives: Tailored enzyme blends to enhance lignocellulosic biomass breakdown.

- Nutrient Supplements: Essential nutrient supplements for microbial growth and fermentation.

- pH Regulators: Precise pH control agents for optimizing enzymatic and microbial activity.

- Bio-Stimulants: Biomolecules stimulating microbial metabolism and biomass utilization.

- Antioxidants: Additives to mitigate oxidative stress during fermentation.

Custom Solutions

- Enzyme Formulations: Customized enzyme blends for efficient biomass saccharification.

- Nutrient Packages: Comprehensive nutrient packages designed for specific biomass types.

- Process Enhancement Agents: Additives to improve fermentation kinetics and yield.

- pH Control Systems: Precision pH control solutions for optimal bioprocessing.

- Technical Support: Expert guidance and consultation for seamless integration.

Key Steps of Our Service

- Formulation Design: Development of custom fermentation additive formulations optimized for lignocellulosic biomass.

- Substrate Compatibility Assessment: Detailed evaluation of substrate compatibility to ensure efficient saccharification.

- Microbial Strain Selection: Identification of suitable microbial strains for biomass fermentation.

- Process Optimization: Fine-tuning of fermentation parameters for enhanced yield and productivity.

Application in Research

- Cellulose Hydrolysis: Enzyme-driven cellulose degradation for bioethanol production.

- Lignin Modification: Enhancing lignin breakdown in lignocellulosic feedstocks.

- Microbial Consortia: Microbial community dynamics in lignocellulosic biomass fermentation.

- Biorefinery Optimization: Strategies for maximizing lignocellulosic biomass conversion.

- Sustainability Metrics: Assessing environmental impacts of bioconversion processes.

CD Biosynsis stands as a trusted partner offering a suite of antibiotic-free fermentation additives and solutions tailored for scientific applications. Our expertise spans custom formulation design, substrate compatibility assessments, microbial strain selection, and process optimization. For inquiries, please contact us to explore how our offerings can elevate your research.

Reference

- Huang, C.; et al. Improve enzymatic hydrolysis of lignocellulosic biomass by modifying lignin structure via sulfite pretreatment and using lignin blockers. Fermentation. 2022, 8(10): 558.

Fig 1. Bioconversion of lignocellulosic biomass to biofuels. (Huang C, et al., 2022)

Fig 1. Bioconversion of lignocellulosic biomass to biofuels. (Huang C, et al., 2022)