Welcome to our advanced enzyme AI design platform - EnzymoGenius™, which specializes in meeting the unique demands of the food and beverage processing sector, particularly in the realm of brewing. Focusing on β-glucanase, we provide customized solutions tailored to the intricate aspects of brewing research.

Role of β-Glucanase in Brewing Process

Beta-glucanases, pivotal for the brewing industry, enzymatically cleave beta-glucan—a polysaccharide in barley, wheat, and oats. This action reduces malt slurry viscosity, enhances saccharification and filtration efficiency, boosts extract yields, and elevates the final brew's quality and yield.

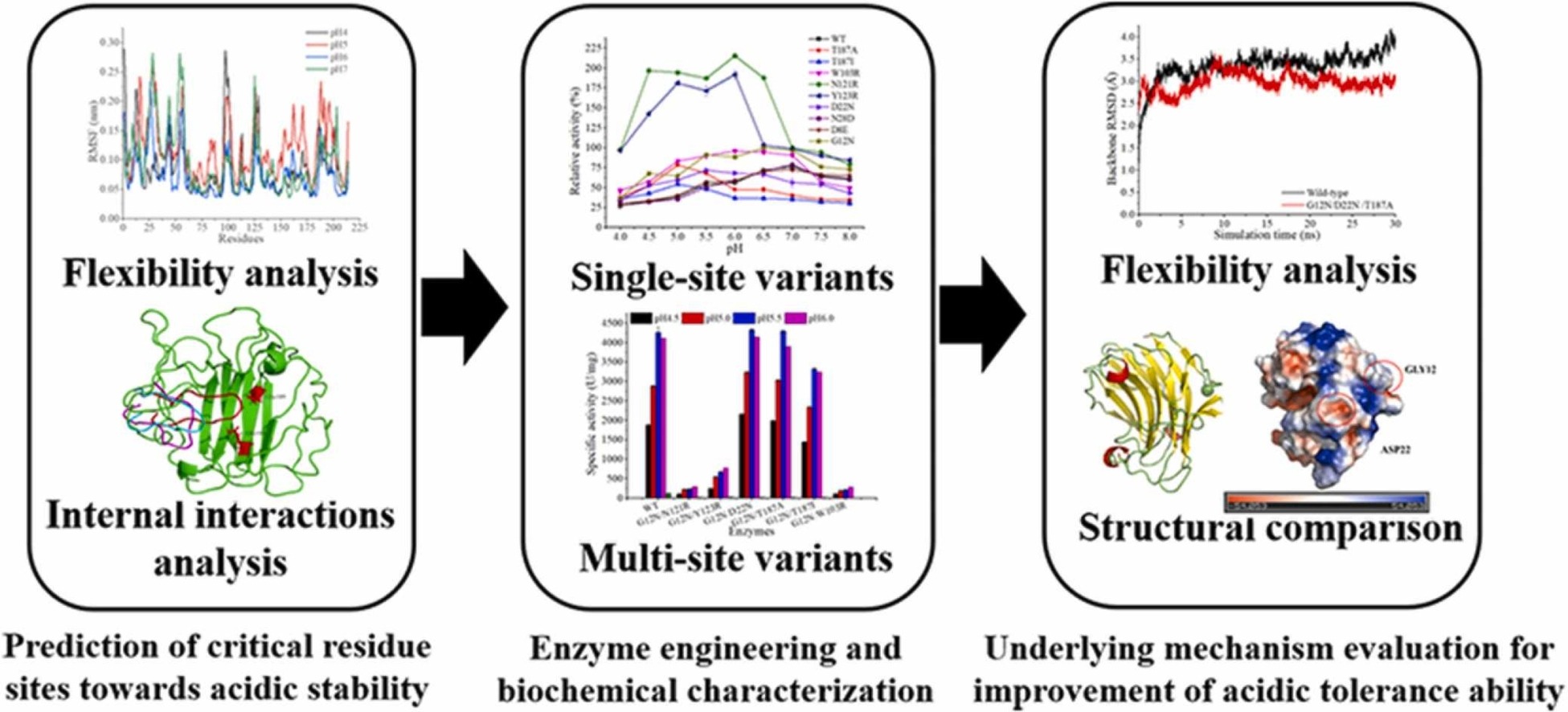

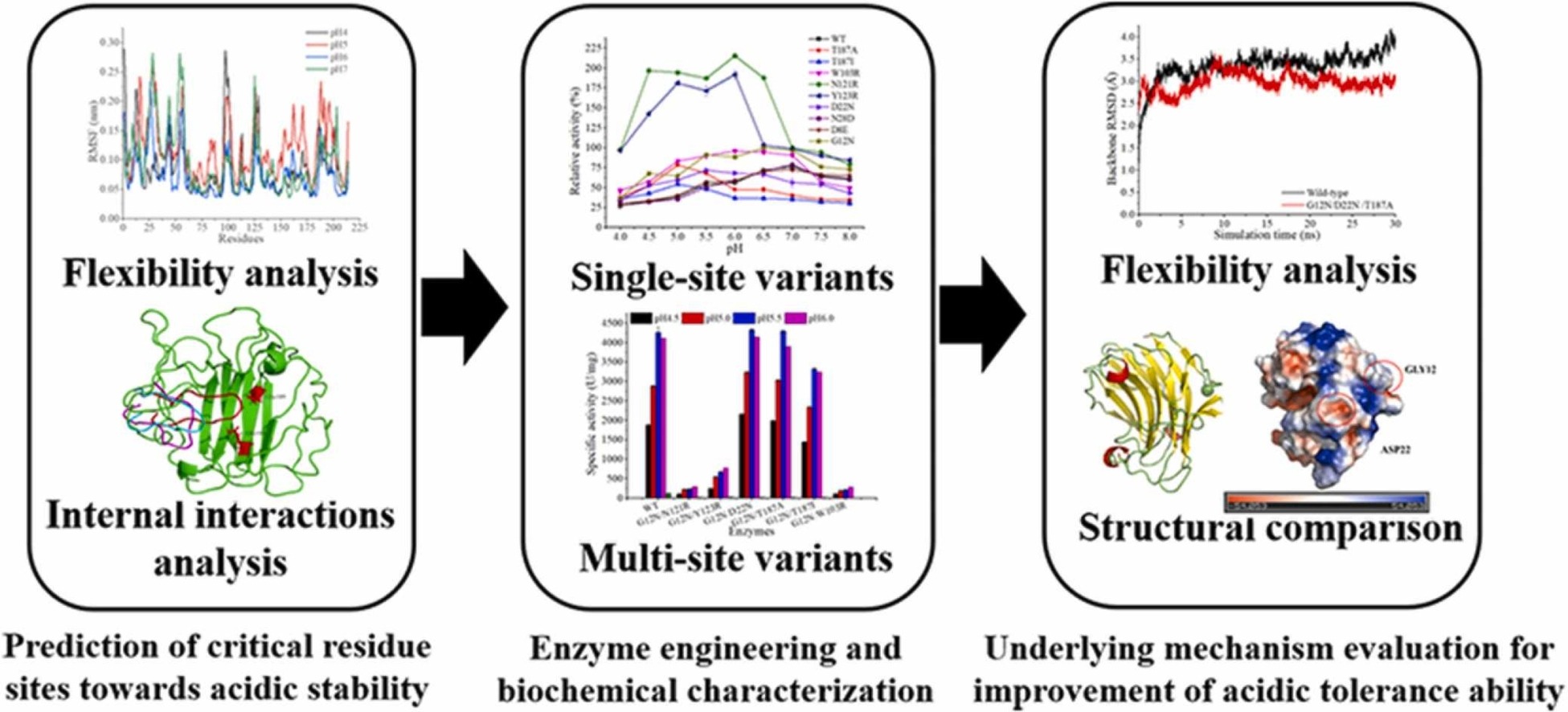

Fig. 1 Enhanced acidic stability of Bacillus 1,3-1,4-β-glucanase by pH-based molecular dynamics simulations. (Chengtuo Niu, et al., 2022)

Fig. 1 Enhanced acidic stability of Bacillus 1,3-1,4-β-glucanase by pH-based molecular dynamics simulations. (Chengtuo Niu, et al., 2022)

Two key β-glucanase types—endoglucanases and exoglucanases—dominate beer brewing. The choice of enzyme formulation and dosage hinges on the brewing process specifics and production type. Ongoing research centers on refining β-glucanases' precision and effectiveness, along with uncovering novel brewing applications. Strategies, including directed evolution, amino acid sequence alignment, and pKa engineering of the catalytic core, enhance the acidic resistance of β-glucanase.

High-quality β-Glucanase

High-quality Xylanase

- Thermostability: β-Glucanase guarantees temperature resilience, ensuring stable brewing results.

- pH Tolerance: β-Glucanase adapts to a wide pH range.

- High Specificity: β-Glucanase demonstrates exceptional specificity in targeting β-glucans, reducing unwanted reactions.

- Enzymatic Efficiency: It boasts remarkable catalytic prowess, needing minimal enzyme for significant impact.

Custom β-Glucanase Solutions

For the entirety of the brewing process, we can provide customized beta-glucanase solutions to support your research for optimal brewing results.

- Mashing Phase Enhancement: Tailored β-glucanase solutions elevate mashing by breaking down β-glucans, reducing viscosity, and aiding in the conversion of carbohydrates to fermentable sugars.

- Filtration Improvement: Post-mashing, our β-glucanase solution dismantles sticky β-glucans, streamlining filtration and lye wash to minimize clogging, enhancing clarity, and refining the brew's quality.

- Fermentation Optimization: Our β-glucanase solution streamlines fermentation sugar production, vital for yeast fermentation and overall process efficiency.

- Quality and Flavor Enhancement: With heightened enzyme activity, our bespoke β-glucan solution adeptly regulates beer attributes—body, alcohol content, and sweetness—yielding a sleek and clear brew.

Services Process for β-Glucanase Design and Optimization

1. Data Collection: We begin by collecting and analyzing data related to your brewing process, including the raw materials used, temperature profiles, and pH conditions.

2. AI-Driven Design: Utilizing cutting-edge AI algorithms, we design a β-glucanase with customized characteristics to meet the specific needs of your brewing process.

3. Optimization: Through iterative simulations, we fine-tune the enzyme's properties to achieve optimal performance.

4. Testing and Validation: The designed β-glucanase is rigorously tested in a lab setting to ensure its functionality and efficiency.

Technical Advantages

- Molecular Biology: Effortlessly blending enzyme structure and function knowledge spawns highly efficient variants.

- Artificial Intelligence: Our platform wields AI's might, shaping tailored solutions with deep learning models adeptly.

- Computational Modeling: Enzymatic reactions replicate via cutting-edge techniques, optimizing performance intricately.

- Bioinformatics: Expertly gathering and decoding vital information in data analysis refine enzyme design adeptly.

- Bioprocess Engineering: Enzymatic innovations seamlessly scale up, integrating into large-scale brewing with engineering principles.

CD Biosynsis, backed by a professional scientific team, is committed to furnishing researchers with enzyme-directed evolution and design services. Our expertise spans the entirety of the food and beverage processing spectrum: food baking, brewing, dairy processing, vegetable and fruit processing, value-added by-products, and food ingredient development. Leveraging AI and synthetic biology synergies, we deliver unparalleled advantages for heightened productivity and superior product quality. For those intrigued by exclusive, tailored enzyme services, don't hesitate to reach out to us.

Reference

- Chengtuo, Niu.; et al. Enhanced acidic stability of a Bacillus 1,3-1,4-β-glucanase through pH-based molecular dynamics simulation for efficient application in brewing industry. Process Biochemistry. 2022, 122(2): 263-271.

Fig. 1 Enhanced acidic stability of Bacillus 1,3-1,4-β-glucanase by pH-based molecular dynamics simulations. (Chengtuo Niu, et al., 2022)

Fig. 1 Enhanced acidic stability of Bacillus 1,3-1,4-β-glucanase by pH-based molecular dynamics simulations. (Chengtuo Niu, et al., 2022)