Enzyme Cofactor Engineering is leading a revolution in biotechnology by improving the efficiency and specificity of enzymes used in industrial processes. The growing importance of this sector is evident in areas such as pharmaceuticals, agriculture, and biofuels. The method improves chemical reactions and makes operations more cost-effective and sustainable. By leveraging enzyme cofactor engineering, we can bolster both yield and quality while diminishing dependence on chemical catalysts.

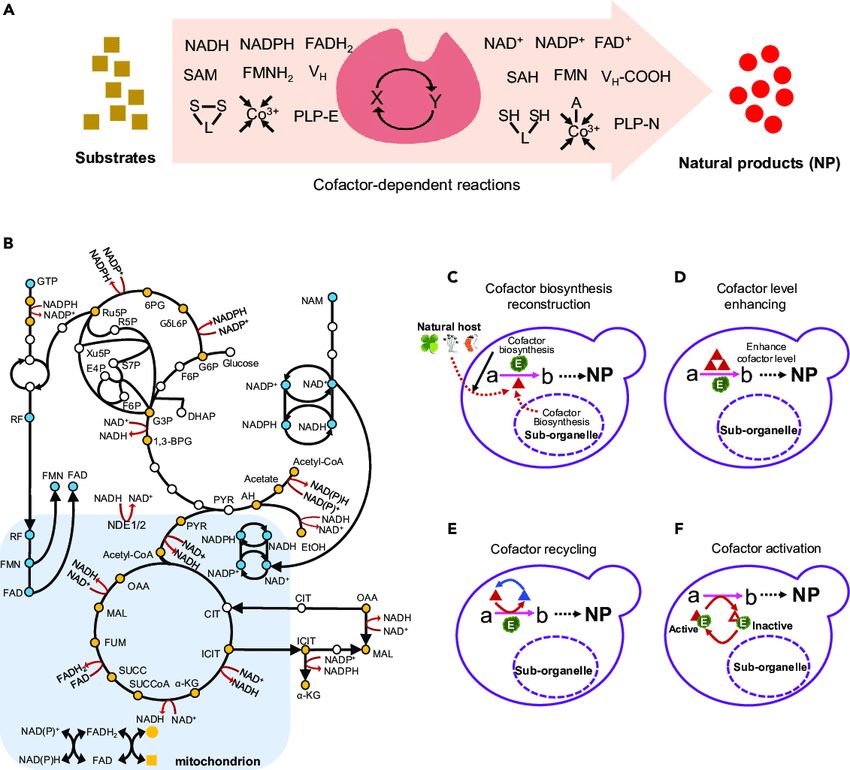

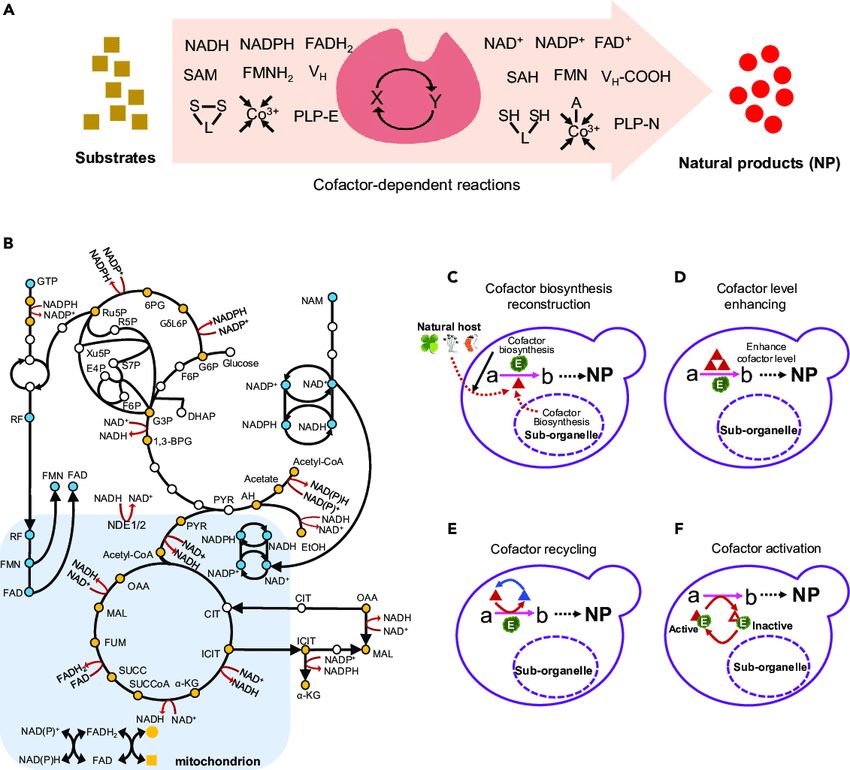

Cofactor Engineering for Enhancing Biosynthetic Efficiency of Natural Products (Ruibing Chen, et al., 2020)

Cofactor Engineering for Enhancing Biosynthetic Efficiency of Natural Products (Ruibing Chen, et al., 2020)

Technical Route

Our Enzyme Cofactor Engineering Technical Route is a meticulously crafted process aimed at enhancing enzyme functionality for various industrial applications. It comprises the following key steps:

| Step Name |

Objective |

Description |

| Identification of Suitable Enzymes |

Identify enzymes suitable for modification |

Thoroughly analyze a variety of enzymes to determine their potential for modification and their relevance to desired biochemical reactions. Consider factors such as natural function, adaptability, and industrial applicability. |

| Computational Modelling and Design |

Design modifications using computational tools. |

Utilize advanced computational models to design targeted modifications to the enzyme structure and composition. Predict how these changes will affect enzyme function with precision, optimizing efficiency and specificity. |

| Practical Application and Lab Testing |

Test modifications in laboratory settings. |

Implement designed modifications in state-of-the-art laboratories, conducting rigorous tests to validate enhanced enzyme activity and stability. Ensure modifications meet safety, efficacy, and reliability standards through thorough testing. |

| Optimization and Scale-Up |

Optimize processes for efficiency and scale-up. |

Fine-tune modifications and process parameters based on lab results to maximize efficiency and productivity. Prepare optimized processes for transition to commercial scale, ensuring cost-effectiveness, efficiency, and sustainability. |

Service Process

Our Enzyme Cofactor Engineering is meticulously crafted to be comprehensive and customized to meet the unique requirements of each client. We prioritize client involvement and transparency, ensuring they are engaged and informed throughout every stage of the process.

- Project initiation and planning: During this crucial first stage, we enter into comprehensive and detailed discussions with our clients, to fully comprehend clients' unique needs, aims, and objectives. A detailed and thorough plan is then meticulously developed, outlining the project's estimated timeline, expected outcomes, and allocation of resources, ensuring all parties have a clear understanding of the project scope and expectations.

- Design & Synthesis: Based on the information gathered during the consultation, our team of expert biochemists will design a custom cofactor specifically tailored to enhance the function of the client's enzyme. This process involves careful molecular design and precise chemical synthesis.

- Testing: After synthesis, we test the new cofactor both in vitro, in a controlled laboratory environment, and in vivo, in a living organism. This is to verify its effectiveness and safety, and to observe any changes to enzyme function.

- Analysis: Following testing, we analyze the function of the enzyme with the new cofactor. This involves detailed biochemical analyses and comparisons between the enzyme's performance with and without the custom cofactor. We provide the client with a comprehensive report detailing these findings.

- Application: Lastly, we collaborate with the client to scale up the process for their specific application. This could involve large-scale cofactor synthesis, incorporation into a production process, or developing a method for the client to produce the cofactor independently. We ensure the process is tailored to the client's needs.

We're here to assist you. If you have any questions, need more information, or would like to discuss a potential project, please don't hesitate to contact us. Our team is always eager to help and share our expertise.

Applications

The power of Enzyme Allosteric Regulation Engineering can be harnessed in various fields. This includes pharmaceuticals, biotechnology, agriculture, environmental science, and many others. Our team, equipped with the knowledge and expertise to apply this technology, can serve a wide range of industries.

| Application |

Description |

| Biocatalysis |

Cofactor engineering is essential in biocatalysis for optimizing enzyme activity and selectivity towards desired substrates. This enables the design of biocatalysts tailored for specific industrial processes, including the production of fine chemicals, pharmaceutical intermediates, and biofuels. |

| Drug Discovery |

Enzyme cofactor engineering is instrumental in drug discovery efforts, particularly in the design of enzyme inhibitors or activators targeting specific metabolic pathways involved in disease progression. By modulating the cofactor binding affinity or availability, this approach enables the development of novel therapeutic interventions with enhanced efficacy and selectivity. |

| Metabolic Engineering |

Enzyme cofactor engineering plays a crucial role in metabolic engineering by altering the specificity or efficiency of enzymes involved in metabolic pathways. This enables the production of desired compounds or the elimination of undesirable byproducts, thereby enhancing yields and process efficiency in various biotechnological applications. |

| Synthetic Biology |

Enzyme cofactor engineering is a fundamental aspect of synthetic biology, allowing the construction of synthetic metabolic pathways and regulatory circuits to produce valuable compounds. By engineering cofactor-dependent enzymes, synthetic biologists can achieve precise control over metabolic flux and product formation, facilitating the development of biologically based solutions for various applications. |

| Environmental Biotechnology |

Cofactor engineering is employed in environmental biotechnology for the development of enzyme-based bioremediation strategies. By enhancing the cofactor specificity or activity of enzymes involved in pollutant degradation pathways, this approach improves the efficiency and effectiveness of bioremediation processes for environmental cleanup. |

FAQs

We recognize that Enzyme cofactor engineering might provoke numerous inquiries. Therefore, we've gathered a series of commonly asked questions regarding this topic. If you don't find the answer you're looking for, feel free to reach out to us.

Q: What are the benefits of enzyme cofactor engineering?

A: Enzyme cofactor engineering offers a myriad of benefits. It provides a cost-effective and environmentally friendly alternative to traditional chemical processes. By optimizing enzymes, we can speed up reactions, thereby reducing production time and costs. Furthermore, it reduces the need for harmful chemical catalysts, contributing to a greener, more sustainable industrial landscape.

Q: How long does the process take?

A: The enzyme cofactor engineering process duration can vary significantly, depending on the complexity of the project. However, our team is committed to efficiency and works diligently to ensure that all projects are completed within a reasonable timeframe without compromising on quality.

Q: Will you provide regular updates on the project?

A: Absolutely. We believe in maintaining open and transparent communication with our clients throughout the project. Regular updates and detailed reports are provided at each stage, ensuring you are always informed about the progress.

Q: Can you work with any type of enzyme?

A: Yes, our team has extensive experience and expertise working with a wide range of enzymes. This allows us to tailor our services to meet your specific needs and ensure the success of your project.

Q: What industries do you serve?

A: We serve a broad range of industries, including but not limited to pharmaceuticals, agriculture, and biofuels. Our versatile approach to enzyme cofactor engineering allows us to adapt to the unique needs of each industry, providing customized solutions for maximum benefit.

Cofactor Engineering for Enhancing Biosynthetic Efficiency of Natural Products (Ruibing Chen, et al., 2020)

Cofactor Engineering for Enhancing Biosynthetic Efficiency of Natural Products (Ruibing Chen, et al., 2020)