Covalent Catalysis Enhancement is a specialized process in which a catalyst forms a temporary covalent bond with a substrate. This bond is crucial as it alters the substrate in ways that significantly lower the activation energy required for the reaction to occur. In the realm of enzymes, this is particularly beneficial. Enzymes are biological catalysts, and by utilizing the Covalent Catalysis Enhancement process, these enzymes can speed up biological reactions dramatically. This results in more efficient and sustainable processes, enhancing productivity and reducing energy consumption.

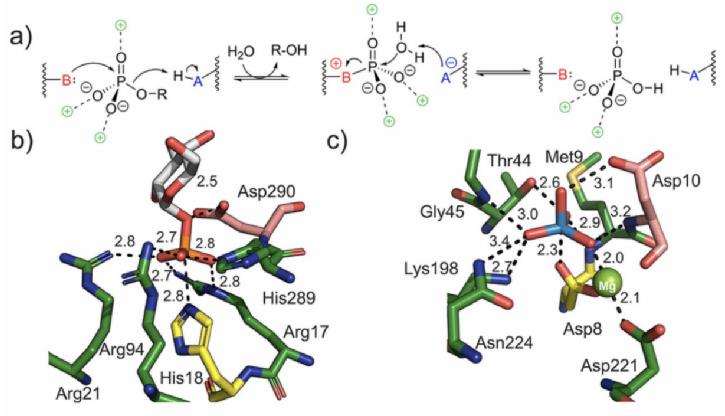

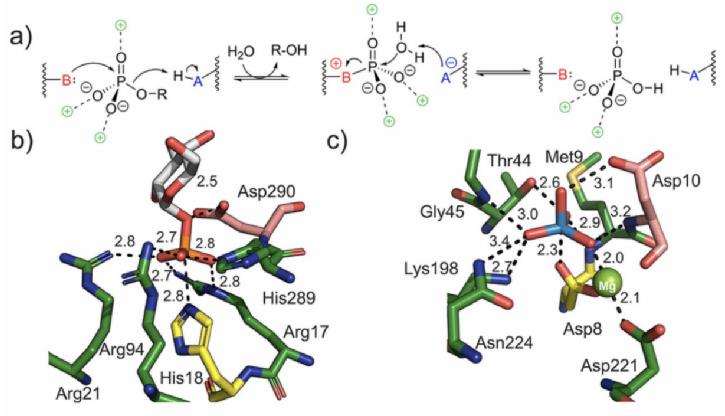

Covalent catalysis in the enzymatic hydrolysis of phosphomonoester substrates (Martin Pfeiffer, et al., 2022)

Covalent catalysis in the enzymatic hydrolysis of phosphomonoester substrates (Martin Pfeiffer, et al., 2022)

Technical Route

The Covalent Catalysis Enhancement Enzyme Technical Route is a comprehensive, methodical approach designed to ensure the optimal utilization and effectiveness of the catalytic process. It's an intricate sequence involving several key stages, each critical to the overall success of the operation:

| Steps |

Objective |

Description |

| Identification and Selection of Suitable Catalysts and Enzymes |

Identify catalysts and enzymes for the desired reaction |

The initial stage involves extensive research and testing to identify suitable catalysts and enzymes. The goal is to select catalysts and enzymes that will efficiently facilitate the desired reaction, ensuring effectiveness and efficiency. |

| Optimization of Reaction Conditions to Maximize the Catalytic Effect |

Maximize catalytic effect through reaction condition optimization |

Once suitable catalysts and enzymes are selected, the next step is to optimize their reaction conditions. This involves adjusting various parameters to maximize the catalytic effect, ensuring optimal conditions for the desired reaction. |

| Monitoring and Analysis of the Reaction to Ensure Desired Results |

Ensure progress and correctness of reaction |

This stage involves continuous observation and analysis of the reaction. The goal is to ensure the reaction progresses as expected, with any deviations or anomalies addressed in real time to achieve the desired results. |

| Scale-Up of the Process for Industrial Applications |

Transition to industrial-scale production |

The final stage involves scaling up the optimized reaction for industrial applications. This step involves transitioning from small-scale testing to full-scale industrial production, ensuring efficiency and effectiveness in the process. |

Service Process

We provide an all-inclusive, meticulous process for the enhancement of Covalent Catalysis:

1. Detailed analysis of needs and process requirements: We deeply explore your operational context, ensuring we capture the complete picture of your situation.

2. Careful selection and optimization of catalysts and enzymes: With the knowledge gained from the initial analysis, we then move on to the careful selection and optimization of the most suitable catalysts and enzymes. This step is based strictly on your specific needs, ensuring that the chosen catalysts and enzymes are the best fit for your processes.

3. Rigorous pilot testing of the enhanced process: Before we move to full-scale implementation, a rigorous and thorough pilot test is conducted. This is a vital step that allows us to ensure the chosen process is effective and efficient, minimizing any potential risks.

4. Full-scale implementation and routine monitoring: Once the pilot testing phase has confirmed the effectiveness of the process, we proceed to full-scale implementation. But our job doesn't stop there. We provide continuous monitoring, regularly checking and adjusting the process as necessary to guarantee optimal performance and the best possible results.

We're here to assist you. If you have any questions, need more information, or would like to discuss a potential project, please don't hesitate to contact us. Our team is always eager to help and share our expertise.

Applications

| Application |

Description |

| Chemical Synthesis |

Covalent catalysis enhancement finds extensive application in chemical synthesis, particularly in the pharmaceutical and fine chemical industries. By leveraging covalent catalysis, researchers can facilitate a wide range of synthetic transformations, including carbon-carbon bond formation, functional group modifications, and asymmetric synthesis. Covalent catalysis enhances reaction rates and selectivity, enabling the synthesis of complex molecules with high efficiency and control. This approach has revolutionized organic synthesis, allowing for the development of novel drug candidates, agrochemicals, and specialty chemicals with improved properties and reduced environmental impact. |

| Enzyme Engineering |

Covalent catalysis enhancement is employed in enzyme engineering to design and optimize biocatalysts for various biotechnological applications. By introducing covalent catalytic residues into enzyme active sites, researchers can enhance catalytic efficiency, substrate specificity, and stability, thereby expanding the scope of enzymatic reactions and improving bioprocess performance. Covalent catalysis enhances enzyme-substrate interactions, accelerates reaction rates, and enables the synthesis of valuable products in biorefineries, biofuels production, and pharmaceutical manufacturing. This approach enhances the sustainability and efficiency of biocatalytic processes, contributing to the development of greener and more sustainable biotechnologies. |

| Drug Discovery and Development |

Covalent catalysis enhancement plays a crucial role in drug discovery and development, particularly in the design of covalent drugs and targeted therapeutics. By harnessing covalent interactions between drugs and their molecular targets, researchers can achieve enhanced binding affinity, selectivity, and efficacy, leading to improved therapeutic outcomes and reduced side effects. Covalent drugs exploit irreversible covalent bonds to form stable complexes with target proteins, resulting in prolonged pharmacological effects and enhanced drug potency. This approach has led to the development of innovative therapies for various diseases, including cancer, infectious diseases, and autoimmune disorders. |

| Materials Science and Engineering |

Covalent catalysis enhancement finds applications in materials science and engineering, particularly in the synthesis and functionalization of advanced materials with tailored properties and functionalities. By employing covalent catalysis strategies, researchers can control the assembly, structure, and properties of materials at the molecular level, leading to the development of novel materials for diverse applications. Covalent catalysis enables the synthesis of polymers, nanomaterials, and supramolecular assemblies with enhanced mechanical strength, chemical stability, and responsiveness. This approach facilitates the design of functional materials for applications in electronics, energy storage, biomedical devices, and environmental remediation. |

| Sustainable Chemistry |

Covalent catalysis enhancement is central to sustainable chemistry, driving the development of eco-friendly and resource-efficient chemical processes. By promoting selective bond activation and transformation, covalent catalysis enables the synthesis of valuable products from renewable feedstocks and waste materials, minimizing the use of hazardous reagents and reducing environmental impact. Covalent catalysis enhances the efficiency and selectivity of chemical reactions, allowing for the development of greener synthetic routes with reduced energy consumption and waste generation. |

FAQs

To gain a deeper understanding of Covalent Catalysis Enhancement, we have compiled an extended list of frequently asked questions, along with their answers:

Q: What types of reactions can benefit from covalent catalysis enhancement?

A: A wide array of biological and chemical reactions can greatly benefit from this technique. This includes reactions involved in drug synthesis, biofuel production, food processing, chemical manufacturing, and many other fields.

Q: How does covalent catalysis enhancement affect the efficiency of a reaction?

A: Covalent catalysis enhancement significantly reduces the activation energy required for a reaction. As a result, the reaction can progress at a much faster pace, thereby significantly boosting overall efficiency.

Q: What industries most commonly use covalent catalysis enhancement?

A: While this technique can be utilized across a wide range of industries, it is predominantly seen in pharmaceuticals, biofuels, food and beverage, chemical manufacturing, and biotechnology.

Q: Can covalent catalysis enhancement be used for industrial-scale reactions?

A: Absolutely. One of the main advantages of covalent catalysis enhancement is its scalability. It can be effectively implemented in reactions of any size, from small laboratory-scale reactions to large industrial-scale processes.

Q: What is the role of enzymes in covalent catalysis enhancement?

A: Enzymes, as biological catalysts, play a pivotal role in this process. They form temporary covalent bonds with the substrate, which dramatically lowers the activation energy required for the reaction and thus speeds up the process.

Q: How is the efficiency of covalent catalysis enhancement measured?

A: The efficiency of covalent catalysis enhancement is typically assessed by measuring the rate of the reaction and the quality of the product. Faster reaction rates and higher-quality products indicate higher efficiency.

Q: Can covalent catalysis enhancement be applied in green and sustainable chemistry?

A: Yes, covalent catalysis enhancement is well-suited to green and sustainable chemistry applications. It can lead to more efficient reactions, lower energy consumption, and reduced waste, all of which are key principles of green chemistry.

Q: What factors need to be considered when implementing covalent catalysis enhancement?

A: Several factors need to be considered, including the selection of suitable catalysts and enzymes, optimization of reaction conditions, and regular monitoring and analysis of the reaction. A comprehensive approach ensures the most effective use of covalent catalysis enhancement.

Q: How can I implement covalent catalysis enhancement in my processes?

A: Implementation typically involves a methodical approach that includes identification and selection of suitable catalysts and enzymes, optimization of reaction conditions, monitoring of the reaction, and scale-up of the process for industrial applications. It is recommended to contact our team of experienced experts to ensure the best results.

Covalent catalysis in the enzymatic hydrolysis of phosphomonoester substrates (Martin Pfeiffer, et al., 2022)

Covalent catalysis in the enzymatic hydrolysis of phosphomonoester substrates (Martin Pfeiffer, et al., 2022)