Specializing in AI-driven enzyme design and optimization, EnzymoGenius™ offers a range of cutting-edge enzyme-based solutions tailored for septic system treatment research. Leveraging the power of artificial intelligence, we provide innovative enzyme products and design processes, revolutionizing the field with state-of-the-art technologies.

Background

Septic system treatment is a vital component of waste management, serving to maintain the ecological balance in residential and industrial settings. It involves the effective decomposition of organic matter, rendering it less harmful to the environment. This process is critical for the sustainability of ecosystems and human health, particularly in areas without access to centralized sewage systems. Septic system treatment utilizes various mechanisms, including enzymatic reactions, to break down complex substances and reduce the impact of waste on the environment.

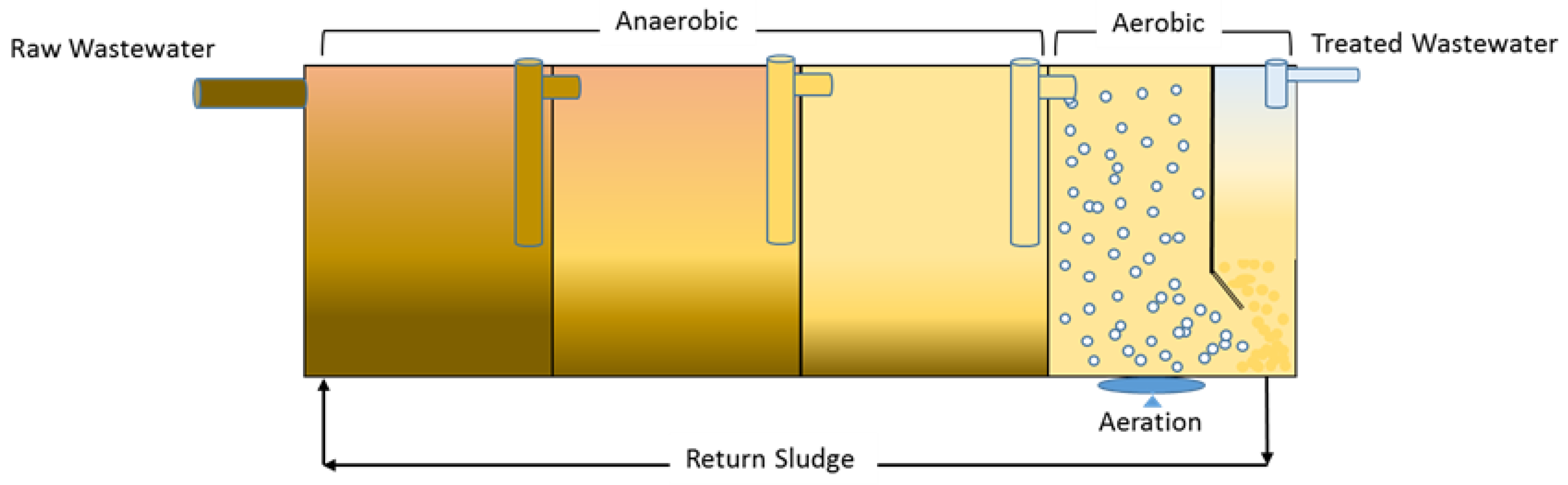

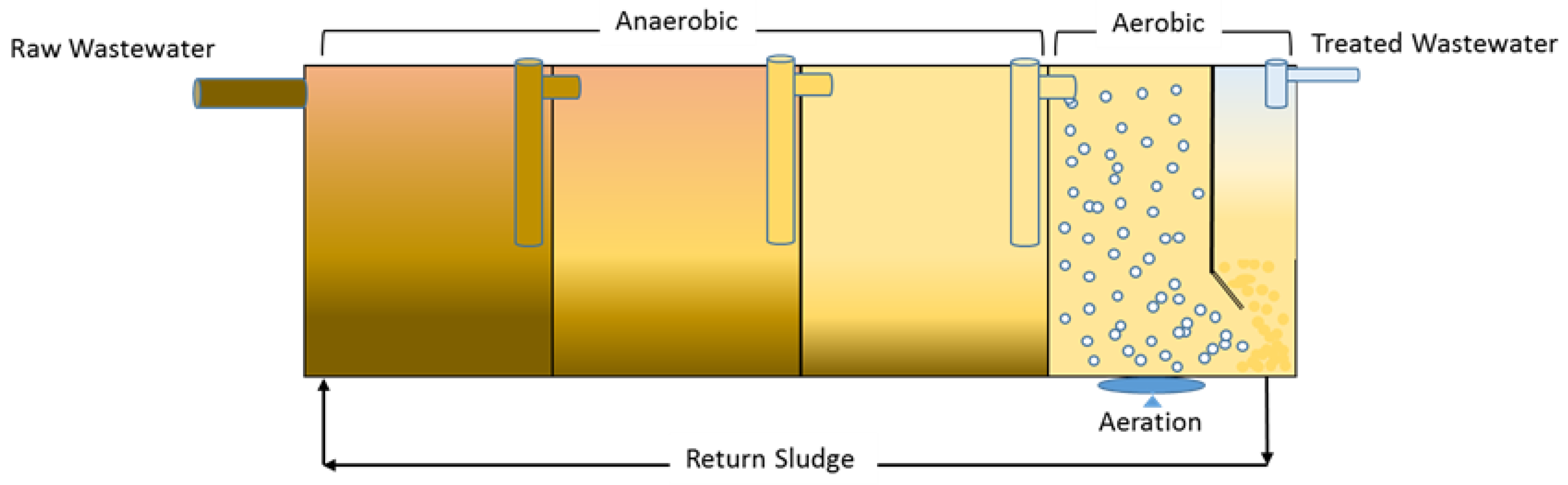

Fig 1. Schematic diagram of the modified septic tank system. (Abbassi B E, et al., 2018)

Fig 1. Schematic diagram of the modified septic tank system. (Abbassi B E, et al., 2018)

Enzymes play a pivotal role in septic system treatment by catalyzing the degradation of organic compounds. Their application principles are rooted in their substrate specificity and efficiency in facilitating biodegradation processes. Research hotspots in this field center around optimizing enzyme cocktails for enhanced septic system performance. Scientists are focusing on developing robust enzymatic formulations that can withstand diverse environmental conditions and effectively target recalcitrant compounds, such as pharmaceutical residues and fats, oils, and grease. Additionally, enzyme immobilization techniques and enzyme-microbe synergy are areas of active exploration, seeking to further improve the sustainability and efficiency of septic system treatment processes.

Products and Solutions Offering

Custom Products

- Digestive Enzymes: Formulated to break down organic matter, cellulose, and fats, optimizing septic tank performance.

- Aerobic Enzymes: Enhance aeration in septic tanks and promote efficient waste decomposition.

- Bioaugmentation Products: Contains beneficial microorganisms and enzymes to boost the natural microbial activity in septic systems.

- Deodorizing Enzymes: Target odor-causing compounds such as hydrogen sulfide and ammonia.

- Pathogen Reduction Enzymes: Designed to reduce harmful bacteria and pathogens, ensuring safer effluent.

Custom Solutions

- Septic Tank Degradation: Enzymes designed for efficient breakdown of organic matter within septic tanks, ensuring optimal waste digestion and reduced sludge accumulation.

- Leach Field Maintenance: Tailored enzymes to enhance soil percolation and prevent clogging in leach fields, prolonging their lifespan.

- Odor Control: Enzymatic solutions to mitigate unpleasant odors associated with septic systems by degrading odor-causing compounds.

- Effluent Quality Improvement: Enzymes targeting the reduction of harmful pathogens and contaminants in effluents, contributing to environmental safety.

- Maintenance and Troubleshooting: Custom enzyme blends for ongoing system maintenance and problem-solving, ensuring the longevity and efficiency of septic systems.

Services Process

1. Data Collection: Gathering relevant information on septic systems, including local conditions, system specifics, and performance requirements.

2. Algorithmic Analysis: Employing AI algorithms to identify enzyme candidates based on substrate specificity, temperature, and pH requirements.

3. Enzyme Design: Crafting novel enzymes or enzyme blends tailored to the septic system's needs, optimizing performance and environmental impact.

4. Validation and Testing: Conducting rigorous in vitro and in vivo tests to ensure the effectiveness of the enzyme products.

5. Continuous Improvement: Leveraging AI to monitor and adapt the enzyme formulations for ongoing enhancement.

Technical Advantages

- Machine Learning Algorithms: Utilizing advanced algorithms to predict enzyme-substrate interactions and design efficient enzymes.

- Bioinformatics: Employing computational biology techniques to analyze biological data and identify potential enzyme candidates.

- Bioreactor Technology: Enabling the large-scale production of enzymes through bioreactors, ensuring cost-effective solutions.

- Metagenomics: Studying microbial communities within septic systems to discover new enzyme-producing organisms.

- Molecular Biology: Manipulating and optimizing enzyme genes for enhanced performance in septic system treatment.

CD Biosynsis excels in enzyme selection, formulation design, optimization, testing, and custom solutions, all facilitated by our AI-driven design process. We employ cutting-edge technologies such as machine learning, bioinformatics, and nanotechnology to deliver the best-in-class solutions. For researchers and businesses seeking to elevate their fabric & household care products, our platform stands ready to drive innovation and efficiency. Contact us to explore the endless possibilities of cleaning and care.

Reference

- Abbassi, B. E.; et al. Modified Septic Tank: Innovative Onsite Wastewater Treatment System. Water. 2018, 10(5): 578.

Fig 1. Schematic diagram of the modified septic tank system. (Abbassi B E, et al., 2018)

Fig 1. Schematic diagram of the modified septic tank system. (Abbassi B E, et al., 2018)