Within the specialized domain of scientific research about the depolymerization of PET (polyethylene terephthalate), EnzymoGenius™ offers an extensive spectrum of enzyme-centric products, services, and solutions, that are meticulously tailored to cater exclusively to the field of PET depolymerization, playing a pivotal role in advancing sustainable material science.

Background

The environmental impact of PET waste, especially single-use plastics, has spurred research into sustainable solutions for PET recycling. One promising approach is enzymatic depolymerization, a process where enzymes, particularly hydrolases, are employed to break down PET into its constituent monomers. The concept of enzymatic PET depolymerization gained traction due to its potential to mitigate the environmental burden posed by PET waste. Enzymes, as biological catalysts, offer several advantages, including specificity, mild reaction conditions, and biodegradability. The research in this area focuses on identifying enzymes with the capability to efficiently hydrolyze PET, leading to the recovery of valuable monomers, such as terephthalic acid and ethylene glycol. This innovative approach not only aids in reducing PET waste but also provides an eco-friendly source of raw materials for PET resynthesis, thus promoting a circular economy in the plastics industry.

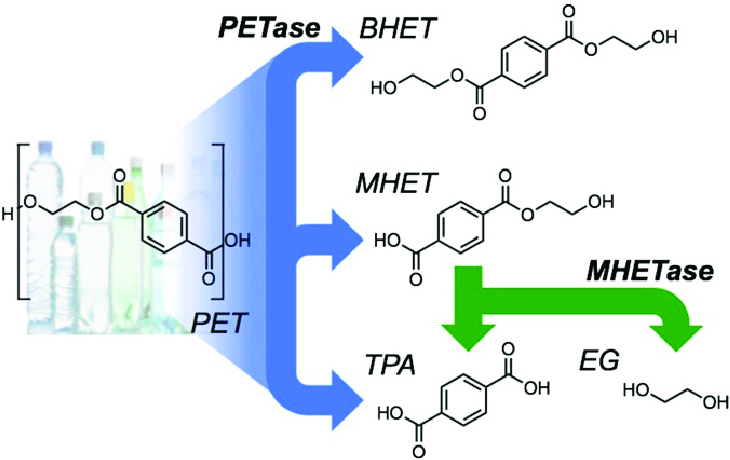

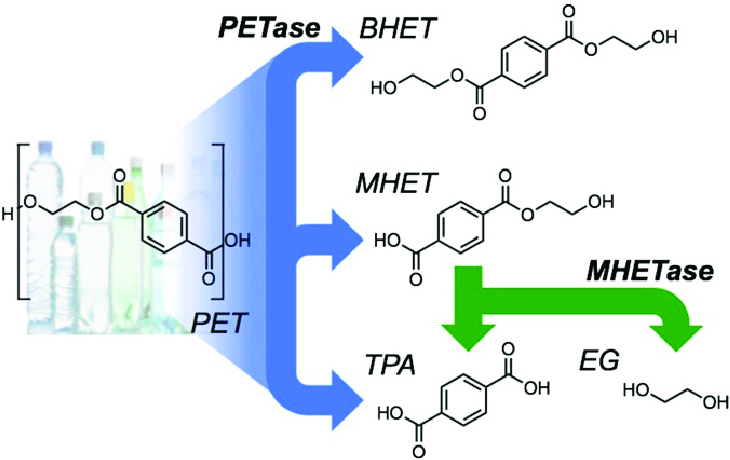

Fig 1. PETase catalyzes the depolymerization of PET. (Austin H P, et al., 2018)

Fig 1. PETase catalyzes the depolymerization of PET. (Austin H P, et al., 2018)

Mechanism of Enzymatic Depolymerization of PET

- Surface Attachment. Enzymes adsorb onto the surface of the PET polymer, facilitated by hydrophobic and electrostatic interactions between the enzyme and the hydrophobic PET surface.

- Hydrolysis. This involves the nucleophilic attack of ester bonds within the PET polymer by the enzyme's active site residues. This leads to the cleavage of PET chains, producing smaller oligomers and eventually monomers.

- Product Release. After hydrolysis, the enzyme releases the hydrolyzed products, typically mono(2-hydroxyethyl) terephthalate (MHET) and terephthalic acid. These products can be further processed for downstream applications or PET resynthesis.

Products and Solutions Offering

Custom Enzymes

- Hydrolases. PETases, cutinases, etc.

- Esterases. Catalyze the hydrolysis of ester bonds in PET.

- Lyases. Break down PET into its constituent monomers by non-hydrolytic means.

- Proteases. Designed to tackle proteinaceous contaminants that often accompany PET substrates.

- Oxidoreductases. Contribute to PET degradation through oxidation-reduction reactions.

Custom Solutions

- Custom-engineered Enzymes: Tailor optimized enzymes for the efficient depolymerization of PET.

- Co-Factor Optimization: Focusing on co-factor utilization to enhance enzyme activity and stability.

- Reaction Kinetics Analysis: In-depth analysis of enzyme-substrate interactions to understand reaction kinetics.

- Enzyme Formulations: Customized enzyme formulations for specific research applications, ensuring compatibility and ease of use.

Process for Design and Optimization of PET Depolymerization Enzyme

1. Sequence Analysis: Identifying potential enzyme candidates with PET depolymerization capabilities.

2. Structural Modeling: Predicting the 3D structures of selected enzymes to guide engineering efforts.

3. Rational Design: Modifying enzyme structures through genetic and computational approaches to enhance PET-degrading efficiency.

4. Directed Evolution: Employing techniques like site-directed mutagenesis to evolve enzymes for improved PET substrate specificity and stability.

5. High-Throughput Screening: Assessing enzyme variants for PET depolymerization performance.

6. Biochemical Characterization: In-depth analysis of selected enzymes, including kinetic parameters and substrate binding.

Applicable Research Fields

- PET Recycling Technologies: Investigating sustainable PET recycling methods.

- Biodegradable Polymers: Exploring enzymatic solutions for biopolymer production.

- Environmental Remediation: Utilizing enzymes to address PET pollution.

- Material Science: Advancing the understanding of PET depolymerization mechanisms.

CD Biosynsis is your dedicated partner in the quest for sustainable solutions. Our comprehensive range of enzyme products and solutions has been meticulously crafted to serve the unique needs of renewable chemicals research. From enzyme identification to cutting-edge technologies, our services are designed to drive the frontiers of sustainable materials science. For more in-depth information or to explore how we can support your research and innovation, please feel free to make contact with us.

Reference

- Austin, H. P.; et al. Characterization and engineering of a plastic-degrading aromatic polyesterase. Proceedings of the National Academy of Sciences. 2018, 115(19): E4350-E4357.

Fig 1. PETase catalyzes the depolymerization of PET. (Austin H P, et al., 2018)

Fig 1. PETase catalyzes the depolymerization of PET. (Austin H P, et al., 2018)