CD Biosynsis is a leading expert that has been dedicated to providing researchers with a wide range of enzyme design services for a long time. Particularly, we focus on enzyme immobilization design strategies to improve enzyme stability, reusability, and ease of isolation. By coating or encapsulating enzymes on solid supports or substrates, we are able to develop powerful biocatalysts for a wide range of applications including biocatalysis, biosensing and bioremediation.

Overview

As we know, enzyme stability is a key factor limiting its in vitro application. Enzyme coating on solid support materials is a common strategy to improve enzyme stability and to realize the application of enzymes in the industrial field. This enzyme immobilization technique involves attaching the enzyme to the surface of solid support material to form a stable enzyme-coated surface, which can be used to improve the robustness, stability and reusability of the enzyme.

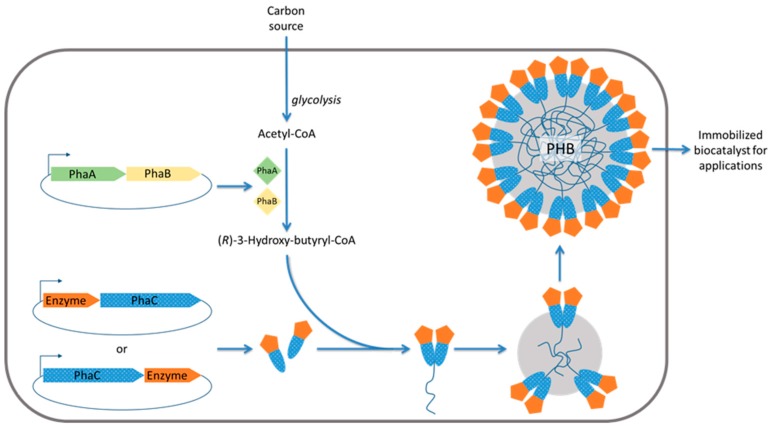

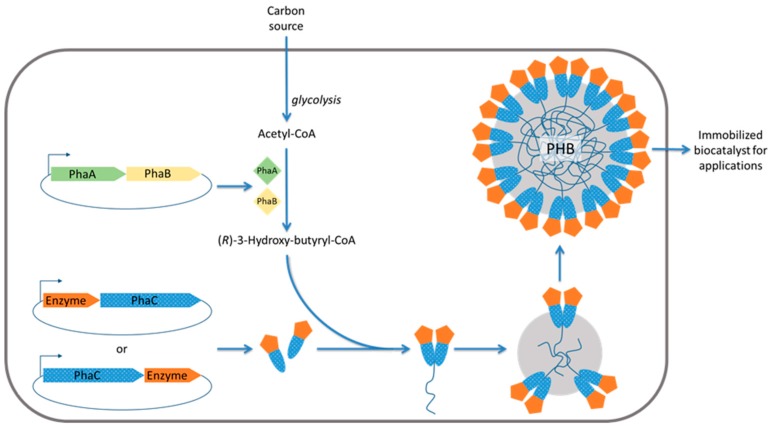

Fig. 1 Schematic outlining in situ formation of polyhydroxyalkanoate (PHA). (Rehm F.B., et al., 2016)

Fig. 1 Schematic outlining in situ formation of polyhydroxyalkanoate (PHA). (Rehm F.B., et al., 2016)

Our Services

Due to the high specificity and efficiency, enzymes play important roles in catalyzing reactions for various industrial processes. However, a major challenge in utilizing enzymes in industrial processes is their limited stability and recoverability in solution. EnzymoGeniusTM platform aims to overcome the difficulties of enzyme applications in the industry by coating enzymes to solid supports or nanoparticles.

We can enhance the robustness of the enzyme by coating it on a solid support in the following manner.

- Physical Adsorption: The target enzyme is physically adsorbed to the solid support by non-covalent interactions.

- Chemical Immobilization: Covalent bonds are formed between the enzyme and the solid support, providing a more stable and stronger attachment.

- Layer-By-Layer Assembly: Alternating deposition of enzymes and complementary polymers on a solid support to form a multilayer coating.

- Encapsulation: The target enzyme is encapsulated in a matrix or coating material to protect it from external factors.

Advantages of Enzyme Coating on Solid Supports

- Enhance Stability

Enzyme Immobilization on a solid support can increase the stability of enzymes and protect them from denaturation and degradation.

- Reusable

Enzyme-coated materials can be easily recycled and reused, reducing costs associated with enzyme consumption.

- Improve Catalytic Activity

Some solid supports can enhance mass transfer and thus improve the catalytic activity of the coated enzyme.

- Ease of Separation

The solid support with magnetic or other separation properties allows for easy recovery of the enzyme-coated material from the reaction mixture.

Applications

- Biocatalysis

Enzyme coating on solid supports can be used in biocatalytic reactions for efficient, reusable catalysis.

- Biosensors

Enzyme coating applied to the surface of biosensors can be used to detect specific biochemical reactions, thus contributing to a sensitive sensor platform.

- Drug Delivery Systems

Enzyme coating solid materials can be used in drug delivery systems, which can modify the release characteristics of drug delivery systems in vivo environment.

- Environmental Protection

Enzyme coating materials can be used in environmental remediation processes to degrade pollutants.

CD Biosynsis provides fast and efficient enzyme research services through our EnzymoGeniusTM platform to enhance enzyme stability and availability for worldwide customers. If you are interested in our services and need more detailed information about enzyme immobilization, please don't hesitate to contact us.

Reference

- Rehm, F.B.; et al. Enzyme Engineering for In Situ Immobilization. Molecules. 2016, 21(10):1370.

Fig. 1 Schematic outlining in situ formation of polyhydroxyalkanoate (PHA). (Rehm F.B., et al., 2016)

Fig. 1 Schematic outlining in situ formation of polyhydroxyalkanoate (PHA). (Rehm F.B., et al., 2016)