01Overview

02Core Service Offerings

03Project Workflow

04Case Studies

05Application Areas

06Frequently Asked Questions (FAQs)

07Contact Us

Overview

CD Biosynsis focus on expression and purification of customize enzyme. Based on a wide variety of expression system and platform, it can provide diversifies expression and purification service to meet the requirement of different customers for expression and purification. Our experienced professional team can process plenty kinds of complicated samples, and provide high quality purification service.

Our service include research as initial stage, proof of concept, optimisation of process and scale up production. Depending on target, we apply different technologies like electrophoresis, chromatography and crystallisation to assure highest quality in our enzymes which guarantees the best catalytic activity.

Besides, we also offer result analysis service for customers to get further insights into the function and structure features of an enzyme.

Whether it is small scale experiments or industrial scale production, you can count on our products. By adopting advanced technologies and processes, we are capable of covering the whole enzyme-expression and -purification procedure, to provide customers with quick and effective services.

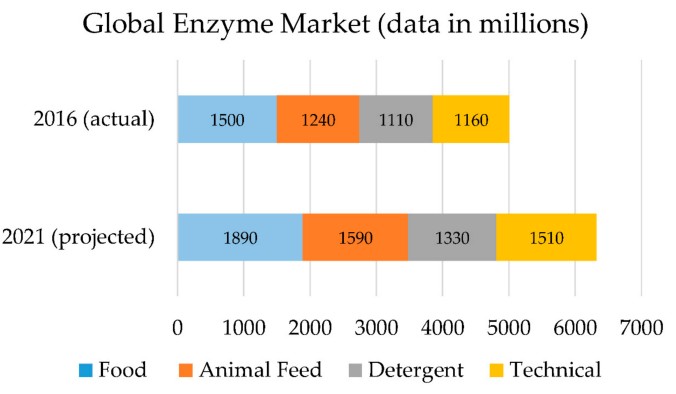

Global enzyme market in 2016 (top) and projected global enzyme market in 2021 (bottom)(J Chapman, 2018)

Global enzyme market in 2016 (top) and projected global enzyme market in 2021 (bottom)(J Chapman, 2018)

Core Service Offerings

According to the needs of different customers, we can provide them with comprehensive and high-quality Enzyme expression and purification solutions. The services we provide are as follows:

Enzyme expression system:

- Expression systems include cell-free expression systems, Escherichia coli expression systems, yeast expression systems and mammalian cell expression systems.

- Support expression needs from small (e.g. 0.5 mg) to large (e.g.>100 kg).

- More than 16 conditions can be screened simultaneously to optimize the expression process.

Enzyme purification technology:

- There are many different methods of purifying an enzyme, including size exclusion chromatography, ion exchange chromatography, hydrophobic interaction chromatography, free flow electrophoresis, affinity chromatography, high performance liquid chromatography (HPLC).

- This product is purified by (1) Ultrafiltration) which dilutes the protein solution, allowing the target protein to pass through a pores, and (2) Lyophilisation) which uses a freeze-drying process to further purify the enzyme.

- Provides comprehensive commissioned services from gene editing to protein production and refining

- Provide customized enzyme screening and optimization services based on customer needs

- Indeed, many compounds can be made from analytical grade up to kilogram grade and beyond to multi-ton scale.

Quality control and analysis:

- Provide quality analysis services for enzymes, including initial and subsequent steps.

- Offers sugar chain analysis and antibody manufacture, as well as solutions for animal testing and genetic modification.

Technical support and consulting services:

- Provides comprehensive consulting services from conception and design to production

Literature survey, Roadmapping, Feasibility assessment, Response optimisation, Scaled-up production and process commissioning

Project Workflow

Our company's Enzyme expression and purification service process:

Demand analysis and consulting

Scale-up production and quality inspection

Retention services and after sales

1. Gene cloning:

- First, the enzyme-encoded gene is amplified through gene-specific primers and restriction enzymes

- Ligate the PCR products to the corresponding cloning vector

- The cloning vector and PCR products are digested and transferred into cells

- Recombinants were selected, confirmed by restriction sectioning, and sequencing that confirmed overall conservation with the Ira L pattern. The positive strains were transformed into E coli.

2. Expression optimization:

- Enzyme expression was performed on a small scale, followed by purification and activity testing

- Fermentation optimization is performed to increase enzyme yield and activity.

- Use different expression systems (for example, the Escherichia coli expression system, or cell-free expression system)

3. Extraction of enzymes:

- Extraction methods include solid substrate culture extraction and cell extraction.

- Cell supernatant (culture medium) was collected and used directly for purification.

4. Purification process:

- This is followed by common purification avenues such as chromatographic method like ion exchange chromatography, gel filtration chromatography, affinity chromatography and high performance liquid chromatography (HPLC) etc.

- Other purification steps may include ultrafiltration and lyophilization to obtain concentrated and purified enzyme

5. Post-purification treatment:

- Conduct enzyme characterization such as evaluation of optimal pH, thermal stability and substrate affinity

- Applying the technique of electrophoretic resolution, the separation of the proteins (one type of large molecule) from the original versus SDS denatured samples was carried out on cylindrical gels made of polyacrylamide.

6. Final product:

This purified enzyme product can be stored for long periods of time or sent around for use in distant locations so the enzyme will retain a stable activity.

Case Studies

Case 1: Gene expression and chromatin extraction of OsExo2

Client project background:

OsExo2 is a rice GH3 family enzyme that may be involved in defences. We will want to understand its function by purifying high purity OsExo2 in vitro.

Solution:

Expression: OsExo2 was cloned into an expression vector and expressed in Escherichia coli BL21 cells.

Primary sonication: Cells were ruptured and the supernatant centrifuged.

Proximate purification: Triple purification using ion exchange chromatography, gel filtration chromatography and affinity chromatography.

Result:

OsExo2 was successfully induced from Escherichia coli, and the isolated protein was filtered in stages. SDS-PAGE analysis found no discernible impurities in the protein so the protein is very pure.

Case 2: Purification and synthesis of Methylaspartate ammonia lyase (MAL)

Client project background:

MAL is a metabolism enzyme involved in the metabolism of amino acids. For its catalytic activity, we require purified MAL enzyme.

Solution:

Expression: MAL gene was cloned into an expression vector and transfected into Escherichia coli BL21 cells for expression.

First filtration: Cells were sonicated and supernatant centrifuged.

Additional purification: Two-step purification by affinity chromatography and ion exchange chromatography.

Result:

MAL was produced from Escherichia coli and purity protein was obtained in several purification steps. The protein stayed stable in enzymatic measurements so that we could probe its catalytic function.

Application Areas

Enzyme expression and purification services have a great variety of utilizations dealing with different kinds of application areas in multiple fields for industries and for research directions.

01

Pharmaceutical R & D:

Enzymes are instrumental for advancements in drug development, such as in gene therapy, antibody drug development and vaccine output: Several teams are utilising expression and purification of enzymes to design novel drug molecules and biologics.

This allows enzyme engineering experts to tailor and optimise protein sequences so that expression and activity can be improved – for example, to enable large-scale production.

02

Food Industry:

The field of food industry benefits from the introduction of enzymes such as alpha-galactosidase to degrade problematic gas-causing foods; alpha-glucosidase which has many advantages, both economic and technical, in industrial production of isomaltooligosaccharides; as well as transglutaminase, which makes a batter with excellent emulsification performance, resulting in lowerusage of emulsifiers and bubbling agents;8F-glucanase improves flour and gluten processing efficiency; and so on.

The use of enzymes in food biotechnology, for example, extends to the cloning, expression and purification of enzymes, essential for the development of novel food additives and improved food products.

03

Agriculture:

Applications belong to crossbreeding of crops, control of pests and development of fertilisers: Xylanase has been produced by recombinant microbial and animal expression systems in mammalian cells, and zinc-containing carboxypeptidases using microbial expression systems have exhibited great cleaning potential by removing hard soil from beets and cesium contaminated plants as well as reducing the cost of wine production.

04

Chemical industry:

Applications of enzymes fall into three areas: 1. biocatalytic reactions, for catalysing chemical reactions; 2. in fine chemical and environmental manufacturing, for biosynthesis and detoxification; and 3. as biomarkers or biosensors for environmental monitoring and diagnosis of disease. It is well-known that huge amounts of energy, toxic chemicals and work are needed to achieve the efficiency of heterologous expression of enzymes for biocatalytic reactions in the chemical industry nowadays.

05

Scientific research:

Many scientific research projects, from basic biology to structural biology and functional analysis, depend on the ability to express and purify an enzyme. One example is to study its functional and structural properties using purified enzymes.

The purification of enzymes also plays an important role in research on epigene regulation, RNA metabolism and DNA repair, to name a few.

06

Clinical and diagnostic:

The various applications range from clinical diagnosis (for determining blood types and levels, detecting diseases related markers, or diagnosing diseases at the genetic level), to forensics and environmental sensing. A great example of a real life application is a recently developed diagnostic technique for exploring unknown compounds in a cell, without having to analyse them individually. It relies on the technique of expressing and purifying enzymes.

07

Textiles and feed:

Use of enzymes in textile industry comprises fibre modification, dyeing removal, and textile modification. While in feed industry, those enzymes are added to improve feed nutrition and digestion.

08

Industrial production:

Fields of industrial application of enzymes are biopharmaceuticals, biofuels, bioplastics and more. For example, a high-efficiency expression and purification system has been used for producing biological drug products.

Frequently Asked Questions (FAQs)

As to Enzyme expression and purification service, the following are customers' question and answer:

Q: What are enzyme expression and purification?

A: The enzyme expression and purification is about expression of enzymes in the host cells using biotechnology and ultrapure enzymes from cell lysates purified. It proceeds through gene cloning, expression, induction, harvest, lysis and purification.

Q: Why enzyme expression and purification?

A: Expression and purification of enzymes is very important for enzyme structure and function research and used as catalysts or biological end products in industrial production. The sterilised enzyme can also be exploited in drug research, diagnostics and biotechnology.

Q: What are the most common enzyme expression platforms?

A: Enzyme expression platforms that are often used are Escherichia coli (E. coli), yeast, insect cells and mammalian cells. There are multiple applications of each system that comes with advantages and disadvantages.

Q: How to choose the right enzyme expression and purification technology?

A: In selecting the right enzyme expression and purification technology, enzyme type (soluble, stable, best yield, cost/value, final target) should be considered. To produce enzymes, for instance, large-scale fermentation and purification might be required.

Q: What is the most typical enzyme purification issue?

A: Enzyme purification is normally accompanied by the enzyme's poor solubility, loss of reactivity, protein blockage and partial extraction of contaminants. Such problems can be overcome by personalising the purification conditions or the purification processes.

Q: How can we verify whether an enzyme is pure and active?

A: Purified enzyme can be determined using SDS-PAGE, HPLC or mass spectrometry. You can evaluate enzyme activity by assessing the enzyme's ability to initiate a reaction. Standard techniques are spectroscopy, electrophoresis and substrate-consumption measurements.

Q: How do you know that enzyme proteins are pure and effective?

A: We use all kinds of chromatography equipment (gel filter, ion exchange, affinity, high performance liquid chromatography, etc.) if necessary, to depurate enzyme proteins, and ultrafilter and freeze-dry. Further, we will provide custom expression systems according to the needs of customers to maintain enzyme proteins at normal function.

If you need high-quality enzyme expression and purification services, please feel free to contact us. Our professional team will provide you with customized solutions to ensure the smooth progress of your project.

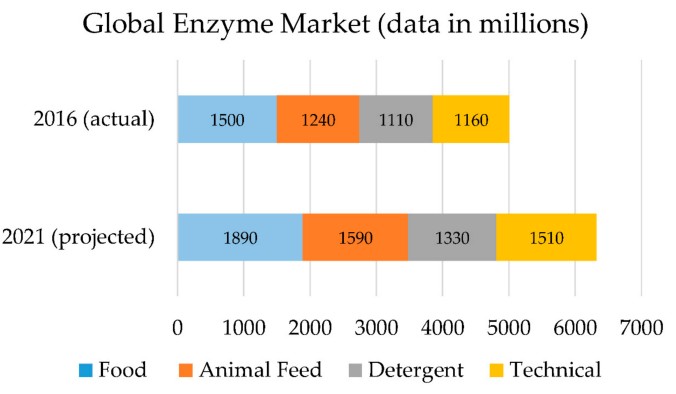

Global enzyme market in 2016 (top) and projected global enzyme market in 2021 (bottom)(J Chapman, 2018)

Global enzyme market in 2016 (top) and projected global enzyme market in 2021 (bottom)(J Chapman, 2018)