Enzyme fermentation represents a highly intricate biological mechanism that exploits the capabilities of microorganisms and their enzymes to scale up enzyme production for commercial purposes. It serves as a fundamental technology across diverse sectors including food processing, pharmaceuticals, bioenergy, and beyond. Understanding and improving the enzyme fermentation process can help us optimize the quantity of enzyme production and improve the efficiency of enzyme production.

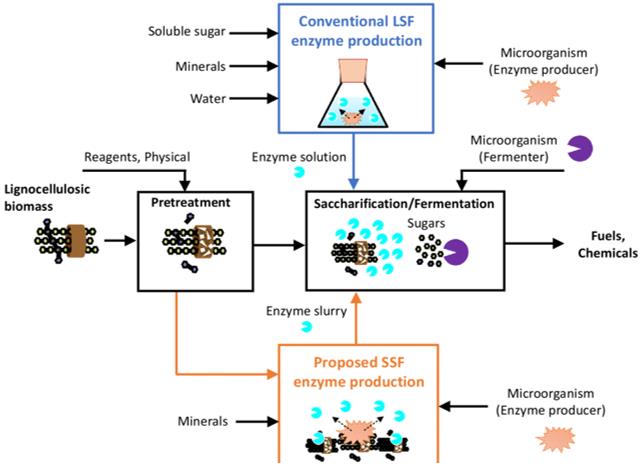

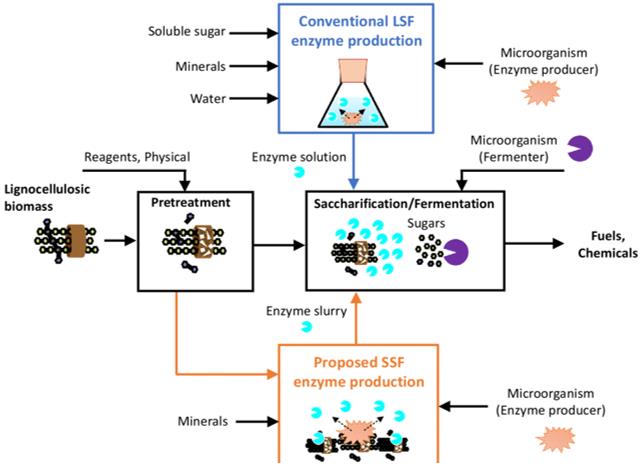

Two methods of on-site enzyme production annexed to the main process line of biomass utilization (Satoru S. and Shigenobu M., 2020)

Two methods of on-site enzyme production annexed to the main process line of biomass utilization (Satoru S. and Shigenobu M., 2020)

Technical Route

Our enzyme fermentation development process is a comprehensive, systematic, and iterative method aimed at maximizing efficiency and yield in enzyme production. This approach is designed to ensure cost-effectiveness and sustainability, making it a crucial asset in our commitment to advancing green technology and environmentally responsible practices. The process is divided into three main stages:

| Stage |

Description |

| Strain Selection |

The initial stage of our method involves identifying and selecting the most productive strains. The choice of strain directly influences the enzyme production yield. Our team meticulously studies various strains, using their extensive knowledge and experience to choose those with high enzyme production potential. This careful selection process is fundamental to our approach. |

| Process Optimization |

After strain selection, we fine-tune the fermentation conditions to optimize enzyme production. We conduct numerous tests and experiments to determine the optimal conditions for maximizing production. This phase involves systematic adjustment and control of parameters like pH, temperature, and nutrient concentration. Through this rigorous optimization process, we create the ideal conditions for enzyme production. |

| Scale-up Fermentation |

The final stage involves scaling the optimized process to industrial levels. This critical step allows us to transition from small-scale operations to large-scale production smoothly. We use advanced equipment and adhere to strict protocols to maintain the quality and yield of enzyme production, even at a larger scale. We ensure that the transition to large-scale production does not compromise quality. |

Service Process

Our service process is comprehensive and meticulously designed to ensure a successful enzyme fermentation development. We follow a five-step process that includes consultation, strain selection and process optimization, trial fermentation, scaling up, and quality control:

- Consultation: The project begins with an initial consultation where we delve into an in-depth discussion about the project scope. This step is crucial as it helps lay the foundation for all the subsequent steps in the process.

- Strain Selection and Process Optimization: Post this discussion, we move onto the selection of the most productive strains. Here, we will optimize the fermentation process, ensuring that it is as efficient as possible. The selection of strains is done meticulously after thorough research and testing to ensure the best results.

- Trial Fermentation: Once the process has been optimized and the strains selected, we then proceed to implement a small-scale trial fermentation. This trial is a critical step as it allows us to evaluate the optimized process in a controlled environment before it is scaled up.

- Scaling Up: If the trial run proves successful, we then proceed to scale up the process to industrial levels. This step is taken with great care and precision to ensure that the larger scale does not compromise the quality or effectiveness of the process.

- Quality Control: Finally, we ensure stringent quality control measures are in place throughout the entire process. Once the final product has been produced, it is rigorously tested to ensure it meets our high standards before delivery.

We're here to assist you. If you have any questions, need more information, or would like to discuss a potential project, please don't hesitate to contact us. Our team is always eager to help and share our expertise.

Applications

Enzyme fermentation development stands at the forefront of modern biotechnology, representing a sophisticated and versatile approach that harnesses the power of microbial enzymes to drive a myriad of industrial processes. This transformative methodology involves the controlled cultivation of microorganisms, often genetically engineered strains, under optimized conditions to produce specific enzymes through fermentation. These enzymes, with their remarkable catalytic capabilities, are then utilized across diverse sectors to enhance processes ranging from pharmaceutical production to environmental remediation. Below is a comprehensive breakdown of the applications and descriptions of enzyme fermentation development across various industries:

| Application |

Description |

| Pharmaceutical Industry |

Enzyme fermentation development plays a pivotal role in the pharmaceutical industry, particularly in the production of biopharmaceuticals such as antibodies, enzymes, and vaccines. Utilizing fermentation processes with tailored microorganisms or cell cultures, this approach yields therapeutic proteins with exceptional purity and specificity, meeting stringent regulatory standards and fulfilling the increasing demand for advanced healthcare solutions. The scalability and reproducibility of enzyme fermentation ensure consistent high-quality output, essential for meeting market demands and advancing medical innovation. |

| Food and Beverage |

Enzyme fermentation development is integral to the food and beverage industry, offering solutions for enhancing product quality, flavor, and shelf life. Through fermentation, enzymes such as amylase, protease, and lipase are produced, facilitating processes like starch hydrolysis, protein breakdown, and lipid modification. These enzymatic reactions improve the sensory attributes and nutritional profile of food products, meeting consumer preferences for natural, clean-label ingredients while optimizing production efficiency and cost-effectiveness for manufacturers. |

| Biofuel Production |

Enzyme fermentation development drives advancements in biofuel production, particularly in the conversion of renewable feedstocks like biomass and agricultural residues into sustainable fuels such as ethanol and biodiesel. Fermentation processes utilizing cellulolytic and hemicellulolytic enzymes efficiently break down complex polysaccharides into fermentable sugars, which are then fermented by microorganisms into biofuels. This approach offers significant advantages including enhanced substrate utilization, reduced energy consumption, and minimized environmental impact, contributing to the development of a greener, more sustainable energy ecosystem. |

| Textile Industry |

Enzyme fermentation development finds application in the textile industry, revolutionizing fabric processing and finishing through enzymatic treatments. Enzymes like cellulase are utilized for processes such as bio-polishing, stone washing, and denim fading, enhancing fabric softness, appearance, and texture. Enzyme fermentation offers eco-friendly alternatives to traditional textile processing methods, reducing water consumption, chemical usage, and environmental pollution, while simultaneously improving production efficiency and product quality to meet evolving consumer demands. |

| Environmental Remediation |

Enzyme fermentation development is deployed in environmental remediation efforts, facilitating the degradation of pollutants and contaminants in soil and water ecosystems. Through fermentation, enzymes capable of breaking down diverse pollutants such as petroleum hydrocarbons, pesticides, and industrial chemicals are produced. These enzymes drive bioremediation processes that offer cost-effective and sustainable solutions for cleaning up contaminated sites, promoting ecological restoration, and safeguarding human health. The utilization of fermentation-derived enzymes enhances the efficacy and efficiency of bioremediation strategies, contributing to the preservation of natural resources and the mitigation of environmental hazards. |

FAQs

Q: Is it possible to enhance the yield of enzyme production through this method?

A: Absolutely. One of the greatest advantages of enzyme fermentation is its potential for optimization. By carefully adjusting the fermentation conditions and process, we can significantly improve the yield of enzyme production. This optimization not only boosts the efficiency of the process but also contributes to reducing production costs.

Q: Can you create customized fermentation processes to suit specific requirements?

A: Yes, we pride ourselves on providing bespoke solutions tailored to our clients' unique needs. We can develop and fine-tune fermentation processes to meet your specific requirements, thereby ensuring that we deliver a solution that fits perfectly with your project.

Q: Which industries stand to benefit the most from enzyme fermentation?

A: Enzyme fermentation has wide-ranging applications across numerous sectors. A broad spectrum of industries, including the food processing, pharmaceuticals, and bioenergy sectors, among others, can reap significant benefits from this innovative technology.

Q: What is the typical timeframe for the enzyme fermentation development process?

A: The development process timeline for enzyme fermentation can vary significantly. It depends on numerous factors, including the complexity of the project and the specific requirements. Nevertheless, we always strive to deliver high-quality solutions in a timely manner.

Q: Can you achieve large-scale enzyme production?

A: Indeed, our facilities are equipped to scale up the fermentation process to industrial levels. This capability allows us to ensure a consistent supply of high-quality enzymes on a commercial scale, meeting the high demands of various industries.

Q: Do you offer technical support throughout the fermentation process?

A: Yes, as part of our commitment to client success, we provide comprehensive technical support throughout the entire process. We ensure the process runs smoothly and efficiently, right from the initial development stages to the final production.

Q: How do you ensure the quality of the enzymes produced?

A: Quality assurance is a key aspect of our operation. We have stringent quality control measures in place throughout the entire fermentation process. These measures ensure that the enzymes produced meet the highest quality standards, providing our clients with reliable and effective products.

Q: How can I initiate a project with your organization?

A: We welcome new projects and collaborations. If you are interested in initiating a project with us, please reach out to us to discuss your project requirements. We're eager to learn about your needs and explore how our expertise in enzyme fermentation can assist in achieving your objectives.

Two methods of on-site enzyme production annexed to the main process line of biomass utilization (Satoru S. and Shigenobu M., 2020)

Two methods of on-site enzyme production annexed to the main process line of biomass utilization (Satoru S. and Shigenobu M., 2020)