Custom Enzyme Formulation Development is a specialized field that focuses on the creation of highly specific enzyme formulations. These formulations are customized to suit specific applications or industries. This field is essential as it allows for the optimization of biocatalytic processes, improvement of product performance, and assurance of compatibility with other ingredients in a formulation. The study and development of custom enzyme formulations are important as enzymes have a significant role in many industries, including pharmaceuticals, agriculture, and biofuels. They facilitate chemical reactions, enhance efficiency, and often provide eco-friendly alternatives to traditional chemical catalysts.

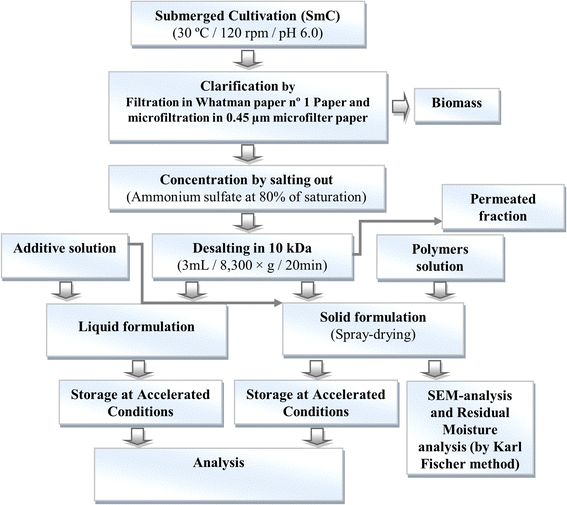

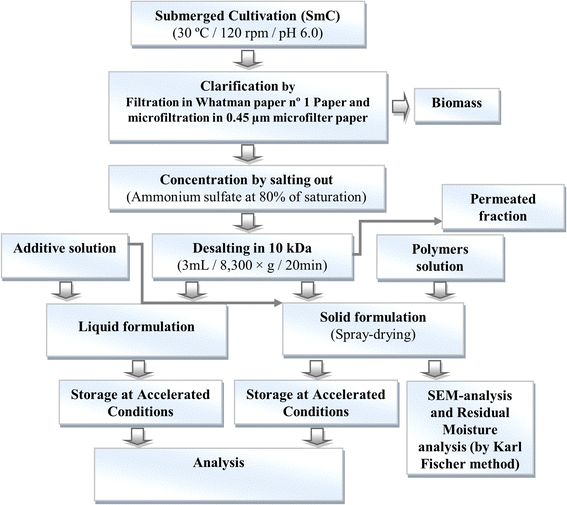

Scheme showing the steps of enzyme production, recovery, formulation and analysis of the liquid and capsule products (Michele Rigon S., et al., 2015)

Scheme showing the steps of enzyme production, recovery, formulation and analysis of the liquid and capsule products (Michele Rigon S., et al., 2015)

Technical Route

Our comprehensive technical route encompasses the following detailed steps:

| Step |

Description |

| Identification of Suitable Enzyme |

Identify an enzyme capable of catalyzing the desired reaction by understanding its characteristics and catalytic abilities. |

| Enzyme Activity and Stability |

Optimize enzyme activity and stability by adjusting factors like temperature, pH level, and substrate concentration to ensure maximum efficiency. |

| Formulation with Additives |

Formulate the enzyme with necessary additives or ingredients to enhance compatibility and performance, considering their impact on the enzyme's functionality. |

| Evaluation under Specific Conditions |

Evaluate the formulated enzyme under application-specific conditions to ensure optimal performance, including activity and stability testing under various environments. |

| Scale-up Production |

Scale up formulation production to meet quantity requirements, ensuring sufficient production to fulfill application needs. |

Service Process

The process of custom enzyme formulation development involves several critical steps to ensure the formulation meets the unique needs and expectations of our clients. Here's a step-by-step overview of our process:

- Our process begins with an initial consultation to understand your specific needs.

- Based on the information from the consultation, we create a custom enzyme formulation tailored to your needs. Our team of experts leverage their experience and knowledge to ensure the formulation matches your specifications.

- The subsequent step involves laboratory testing to verify the formulation's effectiveness. This is followed by iterative optimization, where necessary adjustments and refinements are made to ensure optimal performance under specified conditions.

- Once the formulation's performance meets our standards, we move into the scale-up phase. This involves increasing the production of the formulation to meet your quantity demands, while maintaining quality and effectiveness.

- The final step includes rigorous quality control checks to ensure enzyme stability and effectiveness. Our goal is to ensure the final product meets or exceeds your expectations. Once satisfied with the product's quality, we proceed with delivery.

We're here to assist you. If you have any questions, need more information, or would like to discuss a potential project, please don't hesitate to contact us. Our team is always eager to help and share our expertise.

Applications

We cater to a wide range of industries including pharmaceuticals, biotechnology, food processing, and more. Our services are designed to meet the varying requirements of these diverse sectors. For collaboration or further queries, we invite you to reach out to us.

| Application |

Description |

| Healthcare |

Enzyme formulation development is crucial in healthcare for creating advanced pharmaceutical products, where enzymes serve as integral components of drug delivery systems. These formulations aid in improving drug bioavailability, enhancing stability, enabling targeted release, and reducing side effects. Enzymes can also be engineered to specifically target diseased tissues or cells, offering promising avenues for personalized medicine and targeted therapy. Moreover, enzyme formulations are utilized in diagnostics, with enzyme-linked immunosorbent assays (ELISA) being a prominent example, facilitating sensitive and specific detection of biomarkers for various diseases. |

| Food Industry |

Enzyme formulations are extensively employed in the food industry to enhance food processing efficiency and quality. Enzymes play diverse roles, such as improving flavor, texture, and nutritional value, as well as extending shelf life. They are used in baking to enhance dough handling and bread volume, in dairy processing to accelerate cheese ripening and improve yield, and in beverage production to clarify juices and enhance fermentation processes. Enzyme formulations also aid in the development of functional foods and dietary supplements, offering targeted health benefits. |

| Environmental Remediation |

Enzymes are instrumental in environmental remediation efforts, offering sustainable solutions for wastewater treatment, soil remediation, and the cleanup of contaminated sites. Enzyme formulations are designed to degrade pollutants, such as hydrocarbons, pesticides, and heavy metals, into less harmful or inert substances. They are utilized in bioremediation strategies to enhance the degradation of pollutants in soil and water, contributing to the restoration of ecosystems and the preservation of biodiversity. Enzyme-based technologies are also employed in industrial wastewater treatment plants, reducing the environmental impact of industrial processes and ensuring compliance with regulatory standards. |

| Industrial Applications |

Enzyme formulations find diverse applications in various industrial processes, where they contribute to improving efficiency, sustainability, and product quality. In the textile industry, enzymes are used for biopolishing, desizing, and denim finishing, offering eco-friendly alternatives to traditional chemical treatments and reducing water and energy consumption. In the paper and pulp industry, enzymes aid in pulp bleaching, reducing the need for chlorine-based bleaching agents and minimizing environmental pollution. Enzyme formulations are also integral to detergent manufacturing, where they enhance stain removal, fabric softening, and overall cleaning performance while reducing the environmental impact of laundry processes. |

| Biotechnology |

Enzyme formulation development is essential in biotechnology to produce enzymes used as tools in research, diagnostics, and biopharmaceutical manufacturing. Enzymes are engineered for specific applications, such as DNA amplification in polymerase chain reaction (PCR), protein analysis in mass spectrometry, and drug discovery in high-throughput screening assays. Enzyme formulations are also utilized in diagnostic kits for the detection of diseases, infectious agents, and genetic mutations, enabling rapid and accurate diagnosis. Moreover, enzymes play a critical role in biopharmaceutical production processes, serving as catalysts for the synthesis of therapeutic proteins and antibodies, and as excipients in drug formulations to enhance stability, efficacy, and patient safety. |

FAQs

Below are some frequently asked questions about Custom Enzyme Formulation Development, a specialized field that tailors enzyme formulations to meet the unique needs of various industries. If you have more specific or detailed questions, don't hesitate to get in touch with us directly.

Q: What is the primary objective of Custom Enzyme Formulation Development?

A: The main goal of Custom Enzyme Formulation Development is to create highly effective, specialized enzyme formulations tailored to meet the unique needs of specific industries. These enzyme formulations are designed to enhance efficiency, optimize biocatalytic processes, and ensure compatibility with other ingredients in various industrial applications.

Q: Who are the potential beneficiaries of Custom Enzyme Formulation Development?

A: Custom Enzyme Formulation Development is advantageous for a wide range of sectors. Industries such as pharmaceuticals, agriculture, biofuels, food and beverage, cosmetics, and many more stand to gain substantial benefits from the use of customized enzyme formulations in their processes.

Q: Is it possible to create enzymes tailored to function under specific conditions?

A: Absolutely. We have the technology and expertise to design and develop enzymes that operate optimally under specified conditions. This includes specific pH levels, temperatures, and other environmental or process-related conditions based on your unique requirements.

Q: What is the expected timeline for the development of a custom enzyme formulation?

A: The timeline for the development of a custom enzyme formulation can vary significantly. It is primarily dependent on the complexity of the formulation and the specific requirements of the application. We work closely with our clients to ensure that we meet their deadlines without compromising on quality.

Q: Is it feasible to request changes to the enzyme formulation during the development process?

A: Yes, we are flexible and open to making adjustments to the enzyme formulation during the development process. We aim to meet your specific needs and requirements and are willing to modify the formulation as necessary to achieve optimal results.

Q: Is Custom Enzyme Formulation Development an environmentally friendly process?

A: Yes, indeed. Enzymes are biodegradable and typically have a lower environmental impact than traditional chemical catalysts. This makes the process of Custom Enzyme Formulation Development a more environmentally friendly or "green" alternative.

Q: How is the quality of the enzymes guaranteed in Custom Enzyme Formulation Development?

A: We uphold stringent quality control procedures to ensure the efficacy and stability of our enzymes. We prioritize quality above all else to deliver reliable and effective enzyme formulations to our clients.

Q: Is it possible to scale up the production of the enzyme formulation to meet increased demand?

A: Yes, we can certainly scale up production to meet higher quantity requirements. We have the facilities and capabilities to produce large quantities of the enzyme formulation without compromising on quality.

Q: Do you offer technical support for the developed enzyme formulation?

A: Yes, we do. We provide comprehensive technical support for all our enzyme formulations. This includes troubleshooting, guidance on usage, and assistance with any challenges that may arise during the application of the enzyme formulation.

Q: What is the process of Custom Enzyme Formulation Development?

A: The process begins with an initial consultation to understand your specific needs. We then design the custom enzyme formulation based on your requirements. Laboratory testing is conducted to ensure the effectiveness of the formulation, followed by iterative optimization. Once the formulation is finalized, we scale up production to meet your quantity demands. Quality control checks are then performed to ensure the stability and effectiveness of the enzymes, followed by the final product delivery.

Q: Can you assist with the application of the developed enzyme formulation in our processes?

A: Yes, we can. Our technical team can provide guidance on how to effectively apply the enzyme formulation in your processes to maximize benefits and ensure smooth operation.

Scheme showing the steps of enzyme production, recovery, formulation and analysis of the liquid and capsule products (Michele Rigon S., et al., 2015)

Scheme showing the steps of enzyme production, recovery, formulation and analysis of the liquid and capsule products (Michele Rigon S., et al., 2015)