CD Biosynsis is a leading expert that has been dedicated to providing researchers with a wide range of enzyme design services for a long time. Particularly, we focus on enzyme immobilization design strategies to improve enzyme stability, reusability, and ease of isolation. By coating or encapsulating enzymes on solid supports or substrates, we are able to develop powerful biocatalysts for a wide range of applications including biocatalysis, biosensing and bioremediation.

Overview

Enzymes are catalytically active proteins or RNAs produced in living cells. The use of enzymes in industry has been a challenge due to their poor stability in the in vitro environment. Enzyme immobilization is a technique for attaching enzymes to a support material, which can form a stable and reusable enzyme system in an in vitro environment, and this immobilization technique is particularly advantageous in continuous flow reactors. Continuous flow reaction technique, originated in 1990s, is a new type of technical equipment system developed in many process engineering fields, such as chemical industry, energy and environment, which has the advantages of small volume, low energy consumption, high yield and other properties.

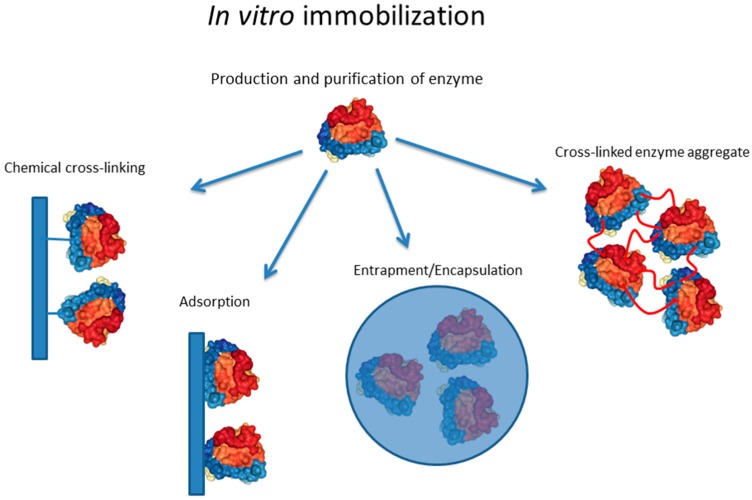

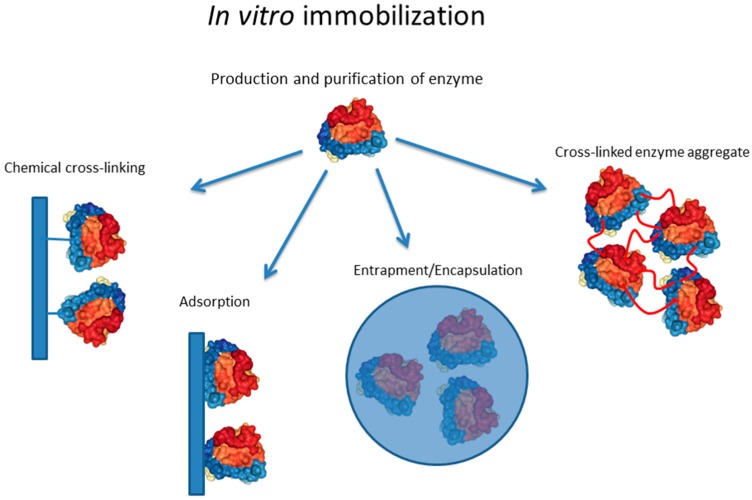

Fig. 1 General methods for in vitro immobilization. (Rehm F.B., et al., 2016)

Fig. 1 General methods for in vitro immobilization. (Rehm F.B., et al., 2016)

Our Services

Due to the high specificity and efficiency, enzymes play important roles in catalyzing reactions for various industrial processes. However, a major challenge in utilizing enzymes in industrial processes is their limited stability and recoverability in solution. EnzymoGeniusTM platform aims to overcome the difficulties of enzyme applications in the industry by coating enzymes to solid supports or nanoparticles.

We can use the following methods to achieve enzyme immobilization in continuous flow reactors.

- Adsorption: Activated carbon, silica, or various polymers are used as support materials, and the target enzyme is adsorbed onto the surface of the support material by non-covalent interaction.

- Covalent Binding: Covalent binding of the enzyme to the functional groups on the support material to achieve a more stable attachment of the enzyme to the support material.

- Encapsulation: By physically encapsulating the target enzyme in a matrix such as a gel or polymer, the target enzyme can be protected and controlled release can be achieved.

Advantages of Enzyme Immobilization

- Better Stability

Immobilized enzymes are generally more stable than free enzymes, making them suitable for long-term use in continuous systems.

- Reusable

Immobilized enzymes can be reused, saving costs and reducing waste.

- Increase Productivity

Continuous flow reactors provide a continuous supply of reactants and removal products, which can increase productivity.

- Controllable Reaction Conditions

Continuous flow systems provide better control of reaction parameters such as temperature and residence time, thus ensuring consistent enzyme activity.

Applications of Enzyme Immobilization

- Biocatalysis

Continuous flow reactors with immobilized enzymes are used for a variety of biocatalytic reactions, including synthetic drugs and fine chemicals.

- Biosensors

Immobilized enzymes in continuous flow systems can be used as biosensors for continuous monitoring of specific analytes.

- Wastewater Treatment

Immobilized enzyme reactors in continuous flow systems can be used to treat industrial wastewater and promote pollutant degradation.

- Biofuel production

Enzyme immobilization in continuous flow reactors can be used for biofuel production, resulting in efficient enzymatic reactions during biomass conversion.

CD Biosynsis provides fast and efficient enzyme research services through our EnzymoGeniusTM platform to enhance enzyme stability and availability for worldwide customers. If you are interested in our services and need more detailed information about enzyme immobilization, please don't hesitate to contact us.

Reference

- Rehm, F. B.; et al. Enzyme Engineering for In Situ Immobilization. Molecules. 2016, 21(10):1370.

Fig. 1 General methods for in vitro immobilization. (Rehm F.B., et al., 2016)

Fig. 1 General methods for in vitro immobilization. (Rehm F.B., et al., 2016)