Enzyme Modification by Immobilization is a scientific process wherein enzymes are attached to certain materials, thereby enabling their repeated usage and controlled action. This is an important area of study as it significantly enhances the efficiency of enzymes in various industrial applications, minimizes associated costs, and paves the way for continuous production processes. By immobilizing enzymes, industries can reap the benefits of these biological catalysts while overcoming the limitations of their sensitive bioactivity and fragility under harsh industrial conditions.

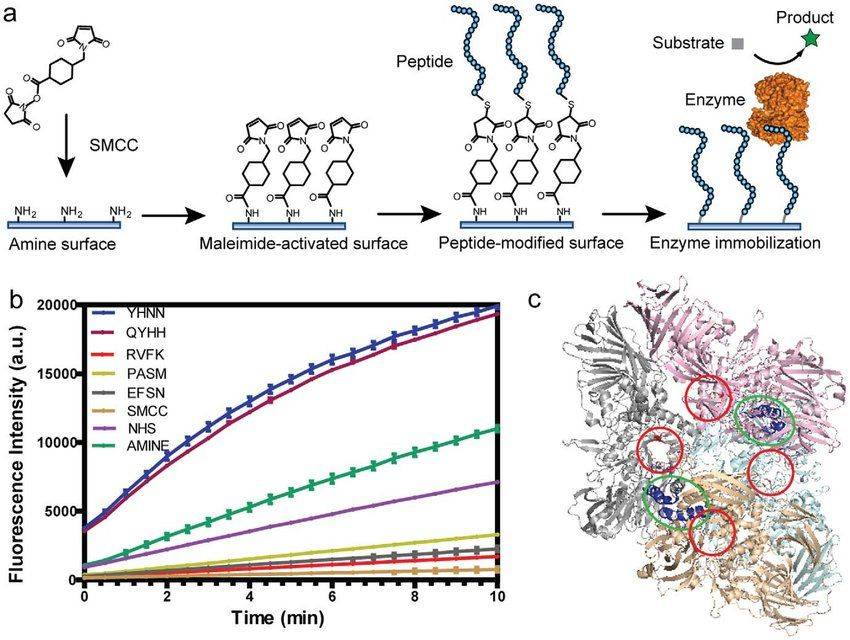

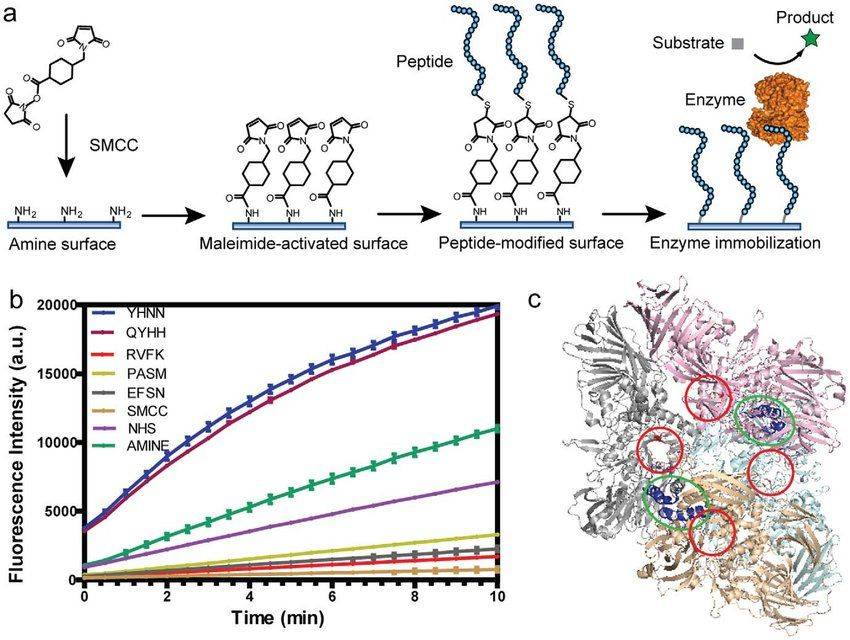

Enzyme immobilization on peptide-modified surfaces (Jinglin Fu, et al., 2011)

Enzyme immobilization on peptide-modified surfaces (Jinglin Fu, et al., 2011)

Service Process

Our thorough and comprehensive service process is meticulously designed to provide you with high-quality immobilized enzymes:

- Intensive Consultation and Detailed Project Planning: Our process kicks off with an in-depth understanding of your unique needs and requirements. This information is then used to meticulously plan the project, ensuring all aspects are taken into consideration.

- Careful Selection of Suitable Enzyme and Immobilization Method: Based on the detailed project requirements and the understanding we've gained, we then proceed to select the most suitable enzyme and the most effective immobilization method to ensure the desired results.

- Precise Enzyme Immobilization: The next phase involves carrying out the immobilization process. This is done under carefully controlled conditions to ensure the enzyme retains its activity and maximum functionality.

- Rigorous Testing and Optimization: Once immobilization is complete, the enzymes are subjected to rigorous testing and optimization processes. This ensures maximum efficiency and effectiveness, and that the enzymes meet the high standards required.

- Safe Delivery of Immobilized Enzymes: Once tested and approved, the immobilized enzymes are securely packed and delivered to you for immediate use.

We're here to assist you. If you have any questions, need more information, or would like to discuss a potential project, please don't hesitate to contact us. Our team is always eager to help and share our expertise.

Applications

| Application |

Description |

| Biocatalysis |

Enzymes are immobilized onto solid supports such as beads, membranes, or nanoparticles to facilitate their reuse and enhance stability. This approach enables efficient catalysis in various industrial processes, including the production of pharmaceuticals, fine chemicals, and biofuels. Immobilized enzymes offer advantages such as improved reaction kinetics, easier separation from reaction mixtures, and enhanced resistance to harsh reaction conditions. Biocatalysis plays a crucial role in green chemistry by enabling environmentally friendly and sustainable manufacturing processes. |

| Biosensors |

Enzymes are anchored onto transducers or surfaces to create biosensing platforms capable of detecting specific analytes in biological samples. Immobilized enzymes catalyze reactions that generate measurable signals, such as changes in pH, conductivity, or fluorescence, in response to the presence of target molecules. Biosensors find applications in medical diagnostics, environmental monitoring, food safety, and security screening. Immobilization enhances the stability and longevity of enzymes, improving the reliability and performance of biosensor devices. |

| Bioremediation |

Immobilized enzymes are employed to degrade pollutants and contaminants in soil, water, and air, offering a sustainable approach to environmental remediation. Enzymes such as oxidases, dehydrogenases, and hydrolases are immobilized onto matrices or carriers to enhance their activity and longevity in harsh environmental conditions. Bioremediation technologies based on immobilized enzymes are used to treat various types of pollution, including hydrocarbons, pesticides, heavy metals, and industrial waste. These approaches mitigate environmental damage and contribute to the restoration of ecosystems. |

| Pharmaceutical Production |

Immobilized enzymes are utilized in pharmaceutical synthesis to improve reaction efficiency, yield, and purity. Enzymes such as lipases, proteases, and oxidoreductases are immobilized onto solid supports or carriers to catalyze key steps in drug manufacturing processes. Immobilization techniques enable the reuse of enzymes, reduce the need for costly purification steps, and enhance the sustainability of pharmaceutical production. Applications include the synthesis of active pharmaceutical ingredients (APIs), chiral intermediates, and drug conjugates. Immobilized enzyme systems offer advantages such as enhanced stereoselectivity, substrate specificity, and operational stability. |

| Biofuel Production |

Enzymes are immobilized in reactors or biorefinery systems for the conversion of biomass into biofuels such as ethanol, biodiesel, and biogas. Immobilized enzyme systems enable efficient hydrolysis of lignocellulosic biomass, starch, or lipid feedstocks into fermentable sugars or fatty acids. Immobilization enhances enzyme stability and recyclability, reducing enzyme usage and operational costs in biofuel production processes. Applications include bioethanol production from agricultural residues, biogas generation from organic waste, and biodiesel synthesis from microbial oils. Enzyme immobilization contributes to the development of sustainable and renewable energy sources, reducing reliance on fossil fuels and mitigating greenhouse gas emissions. |

| Biomedical Applications |

Enzyme immobilization is employed in biomedical research and therapy for targeted drug delivery, diagnostic assays, and imaging techniques. Enzymes are immobilized onto nanoparticles, hydrogels, or surfaces to enhance their biocompatibility, pharmacokinetics, and targeting capabilities. Immobilized enzymes can be engineered to selectively release therapeutic agents or imaging probes in response to specific biological stimuli, such as pH, temperature, or enzymatic activity. Biomedical applications of enzyme immobilization include cancer therapy, tissue engineering, biosensing, and molecular imaging. These approaches offer potential benefits such as improved therapeutic efficacy, reduced side effects, and enhanced diagnostic accuracy. |

FAQs

Here are some frequently asked questions about enzyme immobilization, covering its purpose, methods, advantages, and potential applications in various fields. If you have more specific or detailed questions, don't hesitate to get in touch with us directly.

Q: What is the main purpose of enzyme immobilization?

A: The primary objective of enzyme immobilization is to augment easy separation and reusability of enzymes, bolster operational stability, and enhance their resilience to harsh process conditions. This technology increases the longevity of enzymes, making them more economical and efficient for industrial use.

Q: What are the methods of enzyme immobilization?

A: Several methods can be employed for enzyme immobilization. These include adsorption, covalent bonding, entrapment, encapsulation, and cross-linking. Each method has its advantages and is chosen based on the specific requirements of the process.

Q: Can immobilized enzymes be reused?

A: Absolutely, one of the primary advantages of immobilized enzymes is their reusability. Once the reaction is complete, the immobilized enzymes can be recovered and reused, significantly reducing process costs.

Q: Do immobilized enzymes have the same activity as free enzymes?

A: The activity of immobilized enzymes may be the same, lower, or even higher than that of free enzymes. This largely depends on the method and conditions used for immobilization.

Q: What factors should be considered in the immobilization process?

A: Several factors need to be considered during the immobilization process, including enzyme stability, activity, reaction conditions, and the nature of the substrate. These considerations ensure the immobilized enzyme maintains its activity and is suitable for the intended application.

Q: Can all enzymes be immobilized?

A: While many enzymes can be immobilized effectively, it's not universally applicable. The success of immobilization depends on the specific properties of the enzyme and the chosen immobilization method.

Q: What are the advantages of immobilized enzymes in industry?

A: Immobilized enzymes bring several advantages to industrial processes. They facilitate continuous operation, simplify product separation, enhance enzyme stability, and allow for the enzymes' reusability, thereby reducing costs.

Q: Are there any disadvantages to using immobilized enzymes?

A: Despite numerous advantages, there can be some drawbacks to using immobilized enzymes. These can include potential reduction in enzyme activity and limitations regarding diffusion. However, with careful selection of immobilization methods, these drawbacks can be mitigated.

Q: What is the shelf life of immobilized enzymes?

A: The shelf life of immobilized enzymes varies depending on the specific enzyme and the immobilization method used. However, generally, immobilized enzymes are more stable and have a longer shelf life than free enzymes.

Q: Can immobilized enzymes be used in medicine?

A: Yes, immobilized enzymes have potential uses in various medical fields such as drug delivery systems and diagnostics. Their stability and reusability make them suitable for long-term medical applications.

Enzyme immobilization on peptide-modified surfaces (Jinglin Fu, et al., 2011)

Enzyme immobilization on peptide-modified surfaces (Jinglin Fu, et al., 2011)