01Overview

02Core Service Offerings

03Project Workflow

04Case Studies

05Frequently Asked Questions (FAQs)

06Contact Us

Overview

CD Biosynsis focuses on enzyme process development and is committed to providing customers with efficient and professional enzyme process development services to meet their diverse needs in the biotechnology field. Our services cover everything from enzyme screening and modification to systematic development of fermentation and purification processes, ensuring that the modified mutant enzyme can be applied to actual production with high-quality production efficiency. We not only provide a single enzyme process development service, but also integrate multiple aspects such as design, development, manufacturing and application to provide customers with one-stop solutions. Our team has rich industry experience and advanced experimental equipment, and can efficiently complete various enzyme process development projects, thereby shortening the R & D cycle and improving R & D efficiency.

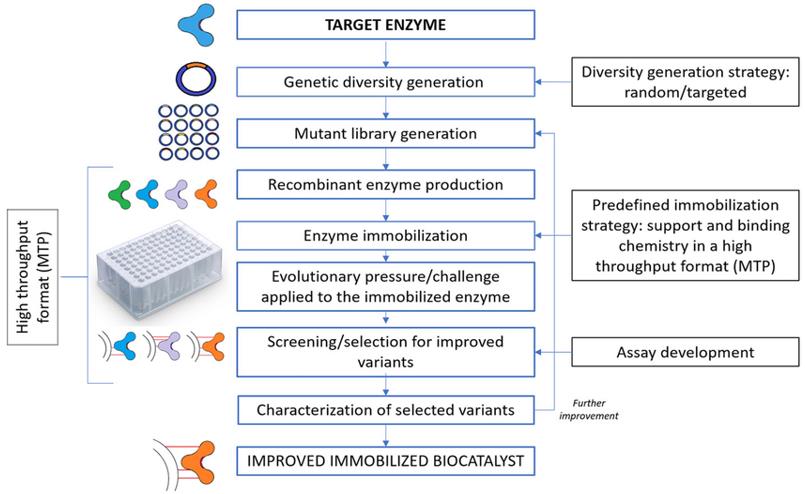

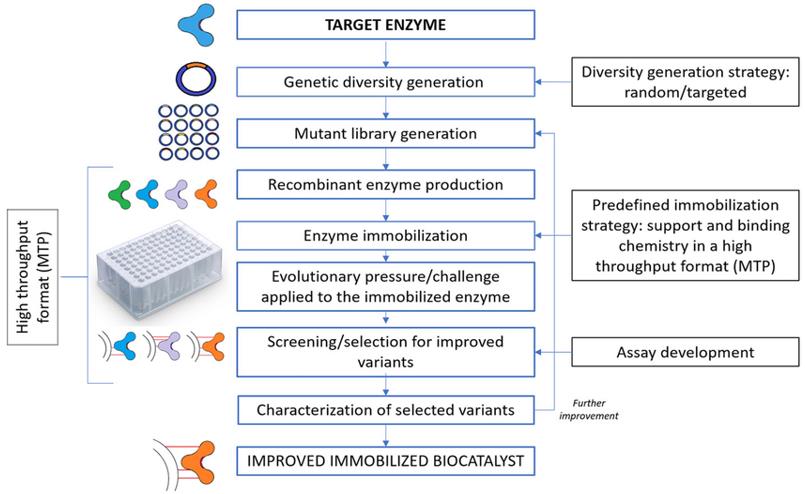

A process of re-engineering enzymes to satisfy the large-scale production (Roha Riaz, et al., 2022)

A process of re-engineering enzymes to satisfy the large-scale production (Roha Riaz, et al., 2022)

Our goal is to help customers optimize and innovate enzyme processes through professional technology and services and promote the development of biotechnology.

Core Service Offerings

The following are the key elements of Enzyme Process Development:

It is an part of the downstream bioprocessing to identify and optimise the expression system to make the enzyme needed. It may be prokaryotic (Escherichia coli, Bacillus) and eukaryotic (Yeast, Insect cells, Mammalian cells) systems.

Coating enzymes with solid carrier materials to make them stable and recycleable. That is choosing the correct immobilisation protocol and immobilisation parameters in the right order.

Use the right solvent in enzyme reactions for better reactions and product decisions.

Using statistics to optimize enzyme-driven reactions such as temperature, pH, substrate concentration, etc. to improve the yield of reactions and the product quality.

For the downstream bioprocessing, learn how to recover and reprocess biocatalyst in a cheaper and more effective way.

Separation and purification of products

Create effective product separation and purification systems to maintain the final product quality and purity.

Application of reaction engineering

Apply reaction engineering concepts to enzyme-driven reactions and to designing more efficient reactors.

Their aim is to create efficient and sustainable enzyme-based processes for supporting biotransformation requirements in the pharmaceutical and other industrial sectors.

Project Workflow

Detailed process of enzyme process development services:

Project start-up and needs analysis

Enzyme screening and optimization

Fermentation process development

Purification process development

Scale-up production and verification

Technology transfer and commercial amplification

Quality control and compliance

1. Project start-up and needs analysis

- Customers put forward their needs for enzyme process development, including enzyme types, functions, expected yields, etc.

- We conduct detailed communication with customers, clarifies project goals and requirements, and signs research and development contracts, stipulating important terms such as technical service content, payment arrangements, key indicators and intellectual property protection

2. Enzyme screening and optimization

- Conduct high-throughput screening to screen out enzymes with the required characteristics.

- The selected enzyme is subjected to directed evolution and modified through genetic engineering technology to improve its catalytic efficiency and stability.

3. Fermentation process development

- Establish an efficient fermentation process platform and use multiple host systems for efficient expression of enzymes.

- Optimize fermentation conditions, such as temperature, pH, oxygen supply, etc., to increase enzyme yield and activity.

4. Purification process development

- Develop suitable purification processes, including pretreatment, separation and purification steps, to ensure high purity and activity of the enzyme.

- Adopt advanced purification technologies, such as chromatography, ultrafiltration, etc., to ensure the quality of enzyme products.

5. Scale-up production and verification

- Scale up small-scale fermentation and purification processes to industrial production scale to ensure process stability and repeatability during the scale-up process.

- Conduct verification experiments for scale-up production to ensure that the scale-up process can stably produce high-quality enzyme products.

6. Technology transfer and commercial amplification

- Transfer the optimized enzyme process to the production platform designated by the customer to ensure that the customer can successfully carry out commercial production.

- Provide technical support and training to help customers master key technologies and operating procedures of enzyme processes.

7. Quality control and compliance

- During the entire enzyme process development process, the quality management system and industry specifications are strictly followed to ensure that products comply with relevant regulations and standards.

Through the above process, we provide a complete set of solutions from enzyme screening, optimization to scale-up production, ensuring that customers can efficiently and with high quality produce the required enzyme products.

Case Studies

Project background:

A company hopes to enhance its competitiveness in the field of enzyme catalysis by establishing a green chemical technology platform. This platform requires the comprehensive use of enzyme catalysis, continuity and other technologies to achieve efficient and environmentally friendly chemical reaction processes.

Solution:

Taking advantage of the company's outstanding advantages in protein structure analysis and design and protein fermentation, an enzyme catalytic process platform has been built. The platform includes multiple links such as high-throughput screening of enzymes, directed evolution of enzymes, enzyme catalytic process development and commercial scale-up.

Result:

Various high-performance enzyme catalytic processes have been achieved that greatly increase production capacity and quality. And the feedback from our customers indicates that not only do these processes save on production costs, they also save on environmental impacts, as envisioned in the growing trend of green chemistry.

Frequently Asked Questions (FAQs)

Regarding the Enzyme Process Development service provided by our company, you may have the following common questions and answers:

Q: What is Enzyme Process Development?

A: Enzyme Process Development involves creating effective enzyme-mediated processes based on science and experimentation to produce specific chemical reactions or biological transformations. It involves many steps such as enzyme selection, optimization, expression, purification and use.

Q: What are the primary features of the Enzyme Process Development service?

A: Enzyme Process Development Services typically consists of the following main elements:

- Gene design: Gene design and synthesis is carried out according to the sequence of the target enzyme.

- Creatinine culture and transfection: choose host cells for gene transfection that carry the needed enzyme.

- Enzyme expression and purification: Optimizing culture and purification yields high activity enzyme proteins.

- Quality inspection and release: Conduct rigorous quality control on enzyme products to check that they are compliant with standards.

Q: How long is the cycle of the Enzyme Process Development service?

A: The cycle of the Enzyme Process Development service varies based on project complexity and customer needs. Generally speaking, screening stable high-expression clones from DNA can be completed within 4-6 months

Q: How to calculate the cost of Enzyme Process Development services?

A: The cost of Enzyme Process Development services will be affected by many factors, including project difficulty, types of raw materials required and consumption. Raw material consumption varies for different projects, so costs will also vary

Q: What are the quality control standards for Enzyme Process Development services?

A: Our service quality control standards strictly comply with the requirements of international regulatory agencies, ensuring that the file system at each link is complete, the source is traceable, and node testing is carried out to guide clone screening.

Q: Do Enzyme Process Development services need to rely on specific intellectual property rights?

A: We respect our customers 'intellectual property rights and ensure that all intellectual property rights are clearly owned during the cooperation process. Some customers want us to transfer the ownership of customized medium formulas to their customers, and we will make arrangements based on specific circumstances and customer needs.

Q: Does the Enzyme Process Development service comply with legal regulations and ethical requirements?

A: Our services fully comply with relevant laws, regulations and ethical requirements, and all projects are performed in accordance with international standards to ensure compliance and ethics

If you have any needs or questions about Enzyme Process Development, please feel free to contact us.

A process of re-engineering enzymes to satisfy the large-scale production (Roha Riaz, et al., 2022)

A process of re-engineering enzymes to satisfy the large-scale production (Roha Riaz, et al., 2022)