Enzyme Purification and Formulation is an intricate process that involves isolating a specific type of enzyme and preparing it for use across a wide range of applications. This process plays a crucial role in both the research and industrial sectors, given that enzymes are the backbone of many biological reactions. It's through this process that we can harness the power of enzymes, making them more accessible and beneficial in various industrial applications.

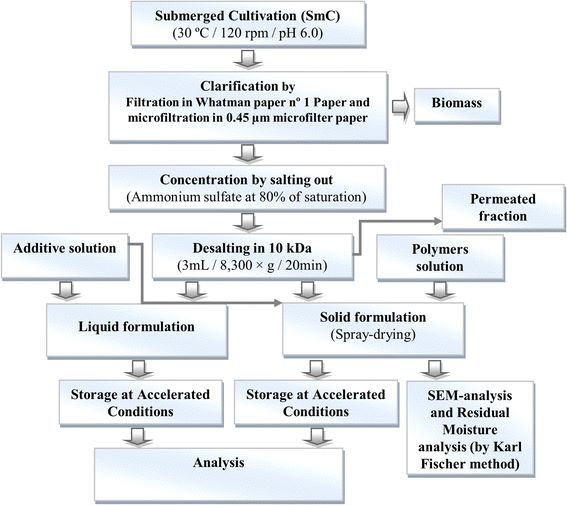

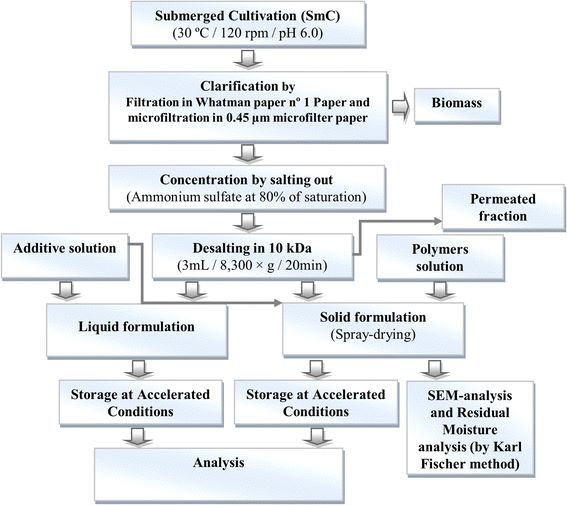

Stages for enzyme production, extraction, formulation, and analysis for liquid and capsule products (Michele R. S., et al., 2015)

Stages for enzyme production, extraction, formulation, and analysis for liquid and capsule products (Michele R. S., et al., 2015)

Service Process

Our service process for Enzyme Purification and Formulation is a meticulously designed and carefully curated journey, ensuring the highest quality and efficiency:

- Consultation and Project Planning: We begin by thoroughly understanding your specific needs. This involves a detailed consultation process where we map out the project plan, set realistic timelines, and define clear objectives.

- Selection and Optimization of Enzyme Source: We carefully select the most suitable enzyme source based on your requirements, then optimize it for maximum efficiency and effectiveness.

- Extraction and Precipitation of Enzymes: This step involves extracting and precipitating the enzymes, allowing for their concentration and partial purification, which is crucial for the following stages.

- Purification of Enzymes: The enzymes are further purified using advanced chromatography techniques, ensuring high purity and concentration, making them ready for formulation.

- Enzyme Formulation: We then formulate the purified enzymes with precision for specific applications, optimizing them for their intended use to increase their effectiveness and durability.

- Quality Control and Delivery: Before delivery, we conduct stringent quality control checks to ensure the product meets our high standards. The final product is then carefully packaged and delivered to you.

We're here to assist you. If you have any questions, need more information, or would like to discuss a potential project, please don't hesitate to contact us. Our team is always eager to help and share our expertise.

Applications

We cater to a wide array of application areas, including pharmaceuticals, biofuels, food and beverages, agriculture, and many more industries. Our commitment to quality and efficiency makes us a trusted partner in these sectors. If you're interested in learning more or discussing potential collaborations, please don't hesitate to contact us.

| Application |

Description |

| Pharmaceutical Industry |

Enzyme purification and formulation are indispensable processes in pharmaceutical production, ensuring the production of safe, effective, and high-quality medications. Purification involves separating the enzyme of interest from other cellular components, contaminants, or by-products to achieve high purity levels. Formulation involves stabilizing the enzyme in a suitable matrix or carrier, optimizing its activity, shelf-life, and compatibility with other ingredients in the final drug formulation. These processes are critical for the development of enzyme-based therapies, such as enzyme replacement therapies, targeted drug delivery systems, and biopharmaceuticals. |

| Food Industry |

Enzyme purification and formulation are vital in the food industry for various applications, including food processing, preservation, flavor enhancement, and nutritional enrichment. Enzymes are purified from natural sources or produced through fermentation processes, then formulated to optimize their activity, stability, and functionality in food products. Common applications include the use of enzymes in bakery products to improve dough handling and texture, in dairy processing to enhance cheese ripening and flavor development, and in fruit juice production to clarify and increase yields. Enzyme formulations contribute to improving process efficiency, product quality, and meeting consumer demands for healthier, sustainable, and clean-label food products. |

| Diagnostic Assays |

Enzyme purification is crucial for the development of highly sensitive and specific diagnostic assays used in clinical diagnostics, medical research, and biotechnology applications. Purified enzymes serve as essential components in various assay formats, including enzyme-linked immunosorbent assays (ELISA), polymerase chain reaction (PCR) assays, and enzymatic immunoassays, enabling the detection and quantification of specific biomolecules, analytes, or pathogens with high precision and accuracy. Enzyme formulations are tailored to optimize assay performance, stability, and reproducibility, ensuring reliable and reproducible results in diagnostic testing. Enzyme-based diagnostic assays are widely used for disease diagnosis, biomarker detection, drug screening, and monitoring therapeutic responses, contributing to advances in personalized medicine, infectious disease control, and biomedical research. |

| Industrial Biocatalysis |

Enzyme purification and formulation are key processes in industrial biocatalysis, where enzymes are harnessed as biocatalysts for synthesizing high-value chemicals, pharmaceuticals, and biofuels in sustainable and environmentally friendly processes. Purification techniques are employed to isolate enzymes with desired catalytic properties, selectivity, and stability from natural sources or recombinant microorganisms. Formulation strategies are applied to immobilize enzymes onto solid supports, encapsulate them in matrices, or modify their structures to enhance their performance, reusability, and operational stability under harsh industrial conditions. Enzyme-based biocatalysts offer advantages such as high specificity, mild reaction conditions, and reduced energy consumption, making them attractive alternatives to traditional chemical catalysts in diverse industrial sectors, including fine chemicals, agrochemicals, and pharmaceutical manufacturing. |

| Therapeutic Enzyme Replacement |

Enzyme purification and formulation are critical for the development and production of therapeutic enzymes used in enzyme replacement therapies (ERT) to treat inherited enzyme deficiencies, metabolic disorders, and other genetic diseases. Purification processes are employed to isolate recombinant or human-derived enzymes to high purity levels, removing contaminants and impurities that may cause adverse effects or immune responses. Formulation techniques are utilized to stabilize therapeutic enzymes in formulations compatible with different routes of administration, such as oral, intravenous, or intrathecal delivery, ensuring their bioavailability, pharmacokinetics, and therapeutic efficacy. Therapeutic enzymes, such as recombinant insulin, enzyme replacement therapies for lysosomal storage disorders, and coagulation factors for hemophilia, provide life-saving treatments for patients with enzyme deficiencies, improving their quality of life and long-term health outcomes. |

FAQs

We recognize that the intricate process of Enzyme Purification and Formulation might lead to numerous inquiries. To address these, we have compiled some of the most frequently asked questions along with their comprehensive explanations:

Q: Could you elaborate on the methods employed in enzyme purification?

A: Certainly, the complex process of enzyme purification involves various techniques. The most common methods include extraction, where the enzyme is separated from its parent organism, precipitation, where enzymes are isolated from the solution, chromatography, a technique used for separation based on the enzyme's properties, and electrophoresis, which is used to separate enzymes based on their size and charge.

Q: What are the factors that influence enzyme formulation?

A: There are numerous factors that can influence the formulation of enzymes. This includes the source from which the enzyme is derived, the desired level of enzymatic activity, the stability of the enzyme in different conditions, and the intended application or use of the enzyme in various industries or research.

Q: How is enzyme activity measured?

A: Enzyme activity is usually determined by the rate at which it catalyzes a specific biochemical reaction. The faster the reaction, the higher the enzyme's activity.

Q: What is the typical duration of the purification process?

A: The duration of the purification process can vary widely. It largely depends on the complexity of the enzyme mixture and the desired level of purity. The more complex the mixture and the higher the purity required, the longer the process will take.

Q: How should enzymes be stored after formulation?

A: In order to maintain their activity and stability, enzymes should be stored in a cool, dry place. This helps to prevent any degradation or loss of activity over time.

Q: How is the quality of purified enzymes ensured?

A: To ensure the highest quality of our enzymes, we adhere to strict quality control procedures. This involves conducting numerous tests to verify the activity, purity, and stability of our enzymes.

Q: Can enzyme formulations be customized for specific applications?

A: Absolutely! We have the capability to tailor enzyme formulations to cater to your specific needs and applications. This flexibility allows us to create unique enzyme solutions for a wide range of industries and research fields.

Q: What is the scale of enzyme production?

A: Our state-of-the-art facilities are equipped to handle both small-scale production for research purposes and large-scale production for industrial applications. This enables us to meet a wide range of demands and ensure a consistent supply of high-quality enzymes.

Stages for enzyme production, extraction, formulation, and analysis for liquid and capsule products (Michele R. S., et al., 2015)

Stages for enzyme production, extraction, formulation, and analysis for liquid and capsule products (Michele R. S., et al., 2015)