Custom Enzyme Purification Development is a specialized service for extracting and purifying enzymes, useful in various applications. Enzymes are biological catalysts that speed up biochemical reactions, making them central to scientific research and industrial processes. Given the critical role of enzymes, our service facilitates their study and use, contributing to advancements in science, medicine, and industry. Our team provides high-quality purified enzymes for diverse research and industrial applications. By comprehending the intricate functions and action mechanisms of these enzymes, we can foster new scientific discoveries and progress. In addition, we also advise clients on the best ways to use and store these enzymes. Our comprehensive service, from extraction to purification, maintains the utmost precision and attention to detail, ensuring the enzymes keep their functional integrity.

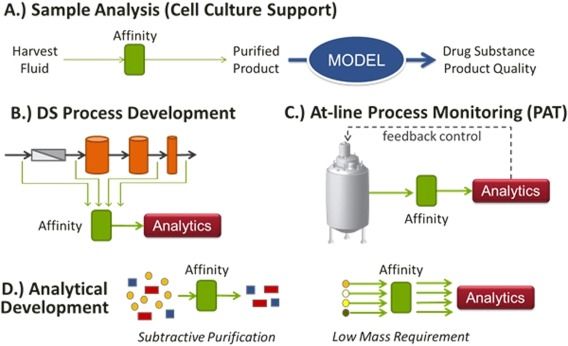

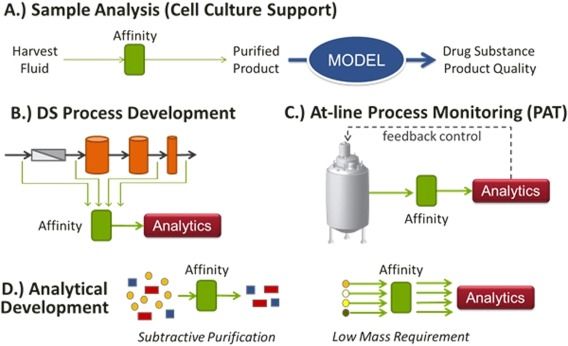

Single-Step affinity purification of enzyme biotherapeutics (Kevin P B., et al., 2014)

Single-Step affinity purification of enzyme biotherapeutics (Kevin P B., et al., 2014)

Service Process

Our service process for custom enzyme purification is designed to be comprehensive and efficient, involving multiple stages:

- Initial Consultation: The first stage involves an initial consultation where we take the time to understand your specific needs and requirements. This step is crucial for us to grasp the nature and scope of the enzyme purification project.

- Design of the Purification Process: Once we have a clear understanding of your requirements, we move on to the process design phase. During this stage, our expert team designs a customized purification process, tailored to effectively purify the specific enzyme in question.

- Execution of the Purification Process: After finalizing the design, we execute the purification process with precision and care. This stage involves actually implementing the designed process to purify the enzyme, ensuring the utmost accuracy and effectiveness.

- Analytical Confirmation of Enzyme Purity: Once the enzyme is purified, it's crucial to confirm its purity. We use a variety of advanced analytical techniques to confirm the enzyme's purity. This stage ensures that the enzyme is free from any contaminants and is in an optimal state, ready for use.

- Quality Control and Assurance: We conduct rigorous quality control checks throughout the process and perform assurance tests to ensure that the purified enzyme meets the highest quality standards. This step is crucial for maintaining the reliability and integrity of our service.

- Packaging and Delivery of the Purified Enzyme: Once the quality is assured, we move to the final stage where the purified enzyme is safely packed and delivered. We ensure that the enzyme is packaged in a suitable format that maintains its activity and effectiveness. Also, we provide detailed instructions for storage and handling.

- Post-Delivery Support and Guidance: Even after the delivery, our service continues. We provide post-delivery support and guidance to our clients, advising on the best ways to use, store, and handle the purified enzymes. This ensures that you are able to make the most out of the purified enzymes.

Through each of these stages, our primary aim is to provide a seamless and efficient service, delivering high-quality purified enzymes to meet your specific needs. If you have any questions, need more information, or would like to discuss a potential project, please don't hesitate to contact us. Our team is always eager to help and share our expertise.

Applications

We cater to a wide range of industries including pharmaceuticals, biotechnology, food processing, and more. Our services are designed to meet the varying requirements of these diverse sectors. For collaboration or further queries, we invite you to reach out to us.

| Application |

Description |

| Biopharmaceuticals |

Custom Enzyme Purification Development plays a critical role in the biopharmaceutical industry, where it is employed to isolate and purify therapeutic enzymes used in drug formulations. This process ensures the removal of impurities and contaminants, resulting in high-quality enzyme products with consistent potency and efficacy for treating various medical conditions. |

| Industrial Biotechnology |

In industrial biotechnology, Custom Enzyme Purification Development is utilized to purify enzymes employed in diverse industrial processes. These enzymes are essential catalysts for the production of biofuels, pharmaceuticals, food ingredients, and other bioproducts. By optimizing purification methods, industrial biotechnologists can enhance enzyme yield, purity, and stability, thereby improving process efficiency and product quality. |

| Enzyme Engineering |

Custom Enzyme Purification Development is integral to enzyme engineering endeavors, aiming to create novel enzymes with tailored properties for specific biotechnological applications. By isolating and purifying engineered enzymes, researchers can evaluate their performance, characterize their biochemical properties, and fine-tune their functionality through protein engineering techniques. This enables the development of enzymes with enhanced catalytic activity, substrate specificity, and stability, expanding their utility in various industrial and biomedical settings. |

| Diagnostic Assays |

Custom Enzyme Purification Development is instrumental in the development of diagnostic assays for detecting biomarkers associated with various diseases and medical conditions. Purified enzymes serve as key components in diagnostic tests, where they catalyze specific biochemical reactions that generate detectable signals or produce measurable products indicative of disease presence or progression. By purifying enzymes to high levels of purity and activity, diagnostic assay developers can enhance the sensitivity, specificity, and reliability of diagnostic tests, enabling accurate and timely disease diagnosis in clinical settings. |

| Agriculture and Biotechnology |

In agriculture and biotechnology, Custom Enzyme Purification Development is employed to isolate and purify enzymes used in crop protection, plant biotechnology, and the production of bio-based products. These enzymes play diverse roles, including facilitating nutrient uptake in plants, enhancing soil fertility, and converting biomass into valuable bioproducts such as biofuels and bioplastics. By optimizing purification strategies, agricultural and biotechnological researchers can obtain highly active and stable enzymes, enabling the development of sustainable agricultural practices and the creation of innovative biobased materials with reduced environmental impact. |

FAQs

Here are some frequently asked questions and their answers about enzyme purification, addressing its importance, common methods, the process of ensuring purity, and more. If you have more specific or detailed questions, don't hesitate to get in touch with us directly.

Q: Why is enzyme purification important?

A: Enzyme purification is not just important, but an essential step in various scientific and industrial processes. It enables in-depth study and understanding of the properties of enzymes, which can be critical for their application in a variety of fields, including but not limited to, medicine, biochemistry, and industrial processes.

Q: What are the common methods used for enzyme purification?

A: The process of enzyme purification is intricate, involving several methods. Some of the most commonly employed ones include precipitation, chromatography, and electrophoresis. These methods, each with their unique mechanisms, enable the effective separation and purification of enzymes.

Q: How do you ascertain the purity of the enzyme?

A: We employ a range of advanced analytical techniques to confirm the purity of the enzyme. These techniques help us ensure that the enzyme is free from any contaminants and is in an optimal state, ready for use.

Q: Can you purify all types of enzymes?

A: Our expertise and capabilities extend to the purification of a wide range of enzymes. For specific requests or needs, we encourage you to contact us so we can discuss the possibilities.

Q: What is the typical timeline for the enzyme purification process?

A: The duration of the enzyme purification process can vary widely, depending on the complexity of the enzyme and the specific requirements of the project. It is not a one-size-fits-all process, and each purification is unique to the enzyme.

Q: Can you scale up the enzyme purification process for industrial applications?

A: Yes, we have the necessary expertise and capabilities to scale up the process in line with the needs and demands of our clients. This includes modifying and adapting the process for large-scale industrial applications.

Q: What are the costs involved in the enzyme purification process?

A: The costs associated with enzyme purification can vary widely, depending on the specific requirements of the project. Factors such as the type of enzyme, the scale of purification, and the complexity of the process can significantly influence the overall cost.

Q: How do you ensure that the enzyme retains its activity during the purification process?

A: We utilize specialized techniques that ensure the enzyme maintains its activity throughout the purification process. This is particularly important as the loss of enzymatic activity can severely compromise the effectiveness of the enzyme.

Q: What are the recommended storage conditions for the purified enzyme?

A: The storage conditions for purified enzymes can vary widely, depending on the specific enzyme. We provide clear and detailed storage instructions to ensure the enzyme remains active and effective.

Single-Step affinity purification of enzyme biotherapeutics (Kevin P B., et al., 2014)

Single-Step affinity purification of enzyme biotherapeutics (Kevin P B., et al., 2014)