01Overview

02Core Service Offerings

03Project Workflow

04Case Studies

05Instrument platform

06Frequently Asked Questions (FAQs)

Overview

CD Biosynsis focuses on Enzyme Scale-Up Production Solutions. From laboratory development to industrial production, we are the one that provides services to make enzymes in industrial scale for customers.

There are hundreds of biochemical reactions using enzymes. Our experts are equipped with technology platforms and decades of expertise to provide customers with an end-to-end solution from enzyme discovery and optimization to scale-up manufacturing. Boosting enzyme production line, we assure the uninterrupted and stable enzyme production on the industrial scale, and technical support as per the customers’ need.

Enzyme Scale-Up Production is enzyme scale up, enzyme purification, testing and app development service. We combine laboratory tools such as molecular breeding, fermentation optimization, separation and purification to supply industrial enzymes for value-added applications such as food, feed and starch.

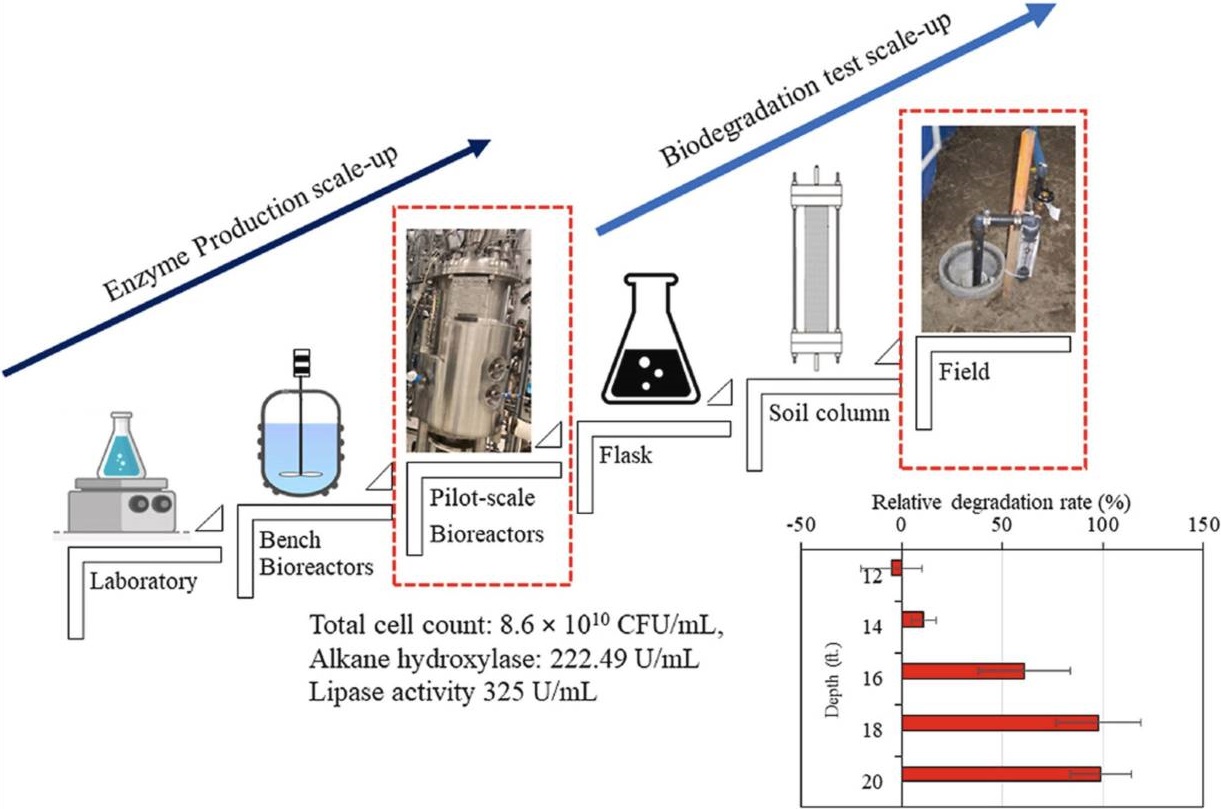

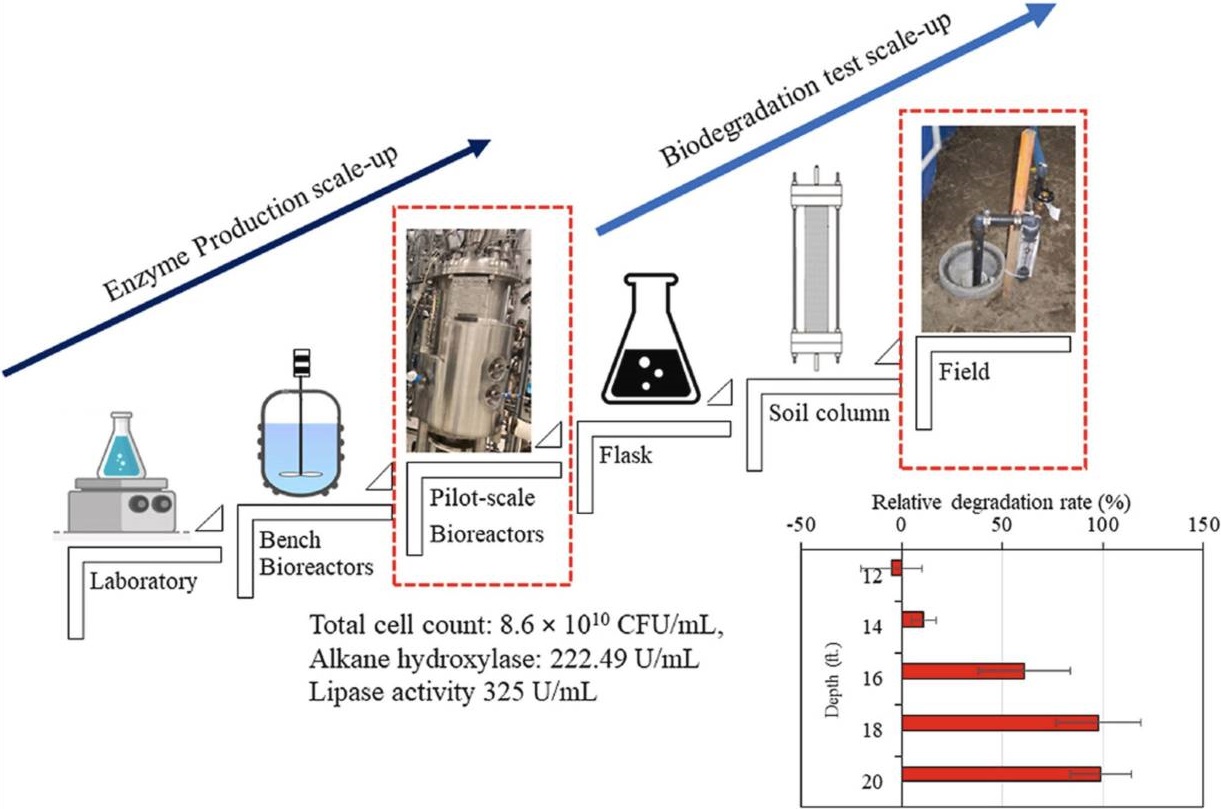

Pilot-scale production and in-situ application of petroleum-degrading enzyme cocktail from Alcanivorax borkumensis (Tayssir Kadri, et al., 2022)

Pilot-scale production and in-situ application of petroleum-degrading enzyme cocktail from Alcanivorax borkumensis (Tayssir Kadri, et al., 2022)

Core Service Offerings

Enzyme Scale-Up Production is mostly for the scale-up of laboratory enzyme production to an industrial level. It is the service that comprises:

Enzyme optimization

Boost the final production titer by optimising enzyme sequences, expression designs, host strains and fermentation conditions. This is a phase to make sure the efficient enzyme activity and yield is preserved during scaling up.

01

Scale-up process development

Create process flows that are scaleable so that small-scale fermentation efficiency and product quality is preserved at scale. That includes anticipating and preventing any errors that might be made during scale-up.

02

Biocatalyst development

Develop the biocatalyst for large-scale production and search for suitable enzyme carriers to improve the application efficiency of enzymes in large-scale catalysis.

03

Downstream processing

Tt is the downstream processing technology after enzyme scale-up manufacturing, filtration, recovery, quality inspection to control the final product purity and stability.

04

Technology transfer

Output the process of production from the lab level to the industrial level to maintain the same production.

05

Project Workflow

Enzyme Scale-Up Production is mostly for the scale-up of laboratory enzyme production to an industrial level. It is the service that comprises:

Project start-up and needs analysis

Technical evaluation and plan design

Scaled-up production preparation

Product purification and quality testing

Scaled-up production execution

1.Project start-up and needs analysis:

Customers first contact us to clarify their needs and goals for enzyme scale-up production.

We will conduct preliminary communication to understand the customer's specific needs, including the type of enzyme required, production scale, expected yield, etc.

2.Technical evaluation and plan design:

Our technical team will conduct a technical evaluation including enzyme stability, activity, and potential production issues as per the needs of the customer.

We will build an individual production strategy based on the evaluation outcomes, selecting production strategies (friction, cell culture, etc.) and optimizing production conditions.

3.Laboratory verification:

Before we scaled up production in the official manner, we ran mini tests in the lab to check the feasibility and performance of the production plan.

This may include the expression, purification and activity testing of the enzyme.

4.Scaled-up production preparation:

Based on the results of laboratory verification, we are ready to scale up the equipment and materials produced.

This includes equipment debugging, raw material procurement and production environment setting.

5.Scaled-up production execution:

Start scale-up production and monitor key parameters in the production process, such as temperature, pH, enzyme activity, etc.

Implement strict quality control measures to ensure that product quality meets standards.

6.Product purification and quality testing:

When production is completed, it gets washed to eliminate impurities and by-products.

- Conduct detailed quality testing such as activity testing, purity test, etc., to make sure that the products are meeting customer needs.

7.Packaging and delivery:

Once you have checked that the product is of a high quality, pack and mark the product.

Delivery is done in the way that the customer has decided so that the product will be delivered safe and on time.

8.After-sales service and support:

Provide necessary technical support and consulting services to answer questions customers encounter during use.

Through this series of detailed processes, we are committed to providing customers with efficient and high-quality enzyme amplification production services.

Case Studies

Background: A drug manufacturer has to increase enzyme production for global market demand. They decided to partner with our CRO service outsourcer for our Enzyme Scale-Up Production knowhow.

Solution: We offer one-stop solution for Enzyme Scale-Up Production from laboratory to the industrial scale. Our group managed to increase production by 30% by tuning the enzyme expression system and manufacturing process.

Result: The pharma company could complete production in time, to accommodate the international markets. They also cut the production costs and made the products better by our technical support.

We have a variety of sizes of fermentors and bioreactors, including laboratory scale, pilot scale and production scale. Our company has strong instrumentation and equipment capabilities in fermentation tanks and bioreactors, automated control systems and membrane filtration technology, which can meet various needs from research and development to production.

Membrane filtration technology

Automation control system

Frequently Asked Questions (FAQs)

Questions frequently asked about Enzyme Scale-Up Production services:

Q: What is Enzyme Scale-Up Production?

A: Enzyme Scale-Up Production is the scale-up from small-scale lab production to industrial production. In this way, we try to keep small-scale fermentation efficient and product quality, and get consistent product quality on larger scale.

Q: Why would we want to scale-up enzyme production?

A: Enzymes are used in food, beverage, etc industries and must be manufactured in large quantity to satisfy the market. To get there, the first step is scale-up production. With scaling-up optimalized, the production costs are effectively reduced and the efficiency of production is maximized.

Q: How does your company offer customised enzyme scale-up manufacturing?

A: We will manufacture enzyme amplification products as per customers ‘demands. Either it is the research quantity or industrial quantity, we can produce and maintain consistency of quality of enzymes through a stringent quality control process.

Q: How to select a scale-up production plan?

A: After we get customer requirement, we will inform customers immediately on technical solution (service goal, service period, service results criteria, sample prep volume, etc.) We’ll discuss the plan with the customer and negotiate for the optimal one considering service content, difficulty coefficient, cycle length, technical parameter needs etc.

Q: What are the most common production scale-up issues?

A: Common problems for scale-up production is the enzyme stability and activity, oxygen transfer and mixing control in massive fermentation. Moreover, one needs to ask also how one infers high-volume production-optimal conditions from small-scale experimental observations.

Q: What should be the enzyme support material?

A: Choosing appropriate enzyme support substrates is one step of scale-up production. The chemical stability, mechanical strength and compatibility with enzymes of the material must be taken into account. Also considered must be the cost-benefit of materials, so that the entire manufacturing chain will be economized.

Q: How can scale-up production be quality and consistent?

A: Scale-up production has to be consistently quality controlled using quality management systems. It means that we control production very accurately, we check it constantly for quality, and we record and analyze the production data very precisely. In this way, production can be kept on the pulse and managed properly to keep the final product of the best quality and consistency.

Pilot-scale production and in-situ application of petroleum-degrading enzyme cocktail from Alcanivorax borkumensis (Tayssir Kadri, et al., 2022)

Pilot-scale production and in-situ application of petroleum-degrading enzyme cocktail from Alcanivorax borkumensis (Tayssir Kadri, et al., 2022)