Our advanced AI-driven enzyme design platform, EnzymoGenius™ specializes in delivering comprehensive glucoamylase design and optimization services tailored exclusively for scientific applications. These services are meticulously crafted to facilitate saccharification and fermentation processes associated with lignocellulosic biomass, addressing the complex needs of researchers and practitioners in this field.

Background

Glucoamylase, a potent starch-degrading enzyme, plays a central role in the saccharification and fermentation of lignocellulosic biomass. This enzyme exhibits unique ability in hydrolyzing α-1,4 and α-1,6 glucosidic linkages in starch, yielding glucose units. Owing to this attribute, glucoamylase has been incorporated into enzymatic strategies for saccharification, the process that effectively breaks down carbohydrates in lignocellulosic biomass, a primary source of renewable energy. In the resultant glucose-rich medium, the fermentation process is streamlined, facilitating the efficient conversion of glucose into biofuels or other valuable biochemicals. Additionally, optimizing glucoamylase activity, stability, and product specificity could offer considerable advancements in the large-scale industrial application of this fundamental enzymatic process.

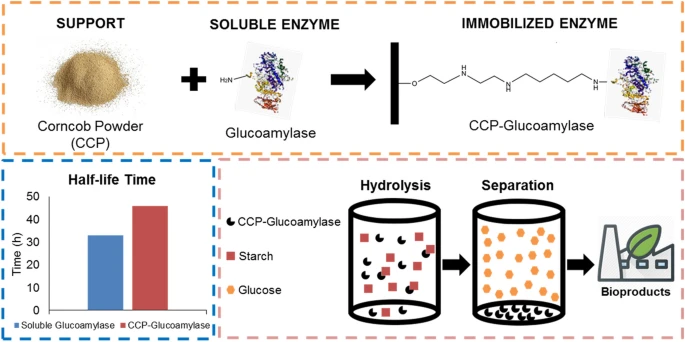

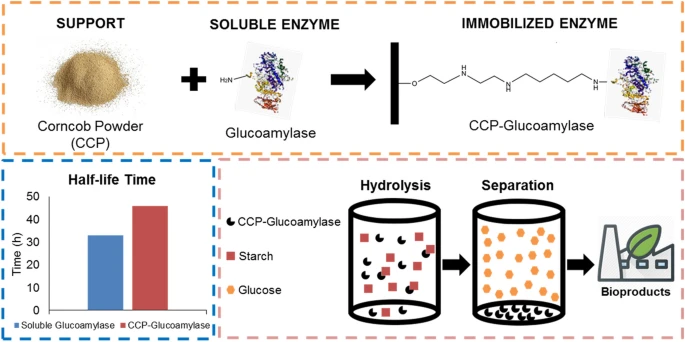

Fig 1. Immobilization of glucoamylase and its application in starch hydrolysis. (da Costa Luchiari, I, et al., 2021)

Fig 1. Immobilization of glucoamylase and its application in starch hydrolysis. (da Costa Luchiari, I, et al., 2021)

Solutions and Products Offering

High-quality Glucoamylases

- Engineered Variants: Tailored glucoamylases with improved substrate specificity.

- Thermostable Enzymes: Heat-resistant variants for elevated process temperatures.

- pH-Optimized Enzymes: Variants adapted to a range of pH conditions.

- High-Yield Enzymes: Designed to maximize sugar yield from lignocellulosic substrates.

Custom Solutions

- Custom Enzyme Design: Personalized glucoamylase optimization based on specific biomass and process requirements.

- Enzyme Formulation: Tailored enzyme blends for enhanced saccharification and fermentation efficiency.

- Process Integration: Expert guidance on enzyme incorporation into biomass conversion processes.

- Continuous Improvement: Ongoing support to adapt enzymes to evolving research needs.

Services for Glucoamylases Design and Optimization

- Sequence Analysis: Evaluating glucoamylase sequences for inherent catalytic potential.

- Molecular Modeling: Utilizing advanced computational tools to predict protein structures and substrate interactions.

- Mutagenesis: Introducing targeted mutations to enhance enzymatic activity and stability.

- Screening and Selection: Identifying high-performing variants through rigorous screening protocols.

- Kinetic Characterization: Quantifying enzymatic kinetics for optimal process integration.

Application in Research

- Biofuel Production: Enzymatic saccharification and fermentation for bioethanol and biobutanol production.

- Biorefinery Processes: Integration into lignocellulosic biorefinery operations.

- Sustainable Materials: Biomass-derived products for sustainable materials and chemical production.

- Agricultural Residue Utilization: Enabling the conversion of agricultural residues into valuable products.

Technical Advantages

- Computational Modeling. Advanced modeling techniques for enzyme design.

- Protein Engineering. Techniques for modifying enzyme properties.

- Bioprocess Optimization. Strategies for optimizing enzyme use in bioprocessing.

- Analytical Tools. High-precision assays for enzyme characterization.

In the pursuit of advancing research and innovation in the conversion of lignocellulosic biomass, CD Biosynsis stands as your dedicated partner. With a focus on personalized enzyme design and optimization, our suite of services and solutions caters to diverse applications, from biofuel production to sustainable materials. For inquiries or to explore how our expertise can propel your research forward, please feel free to contact us.

Reference

- da Costa Luchiari, I.; et al. Glucoamylase immobilization in corncob powder: assessment of enzymatic hydrolysis of starch in the production of glucose. Waste and Biomass Valorization. 2021, 1-14.

Fig 1. Immobilization of glucoamylase and its application in starch hydrolysis. (da Costa Luchiari, I, et al., 2021)

Fig 1. Immobilization of glucoamylase and its application in starch hydrolysis. (da Costa Luchiari, I, et al., 2021)