Our advanced AI-driven enzyme design platform, EnzymoGenius™ specializes in providing comprehensive lipase design and optimization services tailored for the exploration of bioethanol and biodiesel production. We offer a wide array of AI-driven solutions and cutting-edge technologies to empower scientific innovations in this crucial field.

Background

Lipases, otherwise known as triacylglycerol acylhydrolases, demonstrate a critical function in biodiesel production by aiding the esterification and transesterification of vegetable oils and fats. Their role in bioethanol production is centered around elevated hydrolysis of fat, which is instrumental in enhancing the yield of the process. Lipases incorporated in biodiesel production are mostly of microbial origin, primarily because of their robustness, and considerable tolerance to the conditions prevalent during biodiesel production. Moreover, immobilization of lipases, a technique designed to increase their durability and reusability, has been found to improve their efficacy in biodiesel manufacturing.

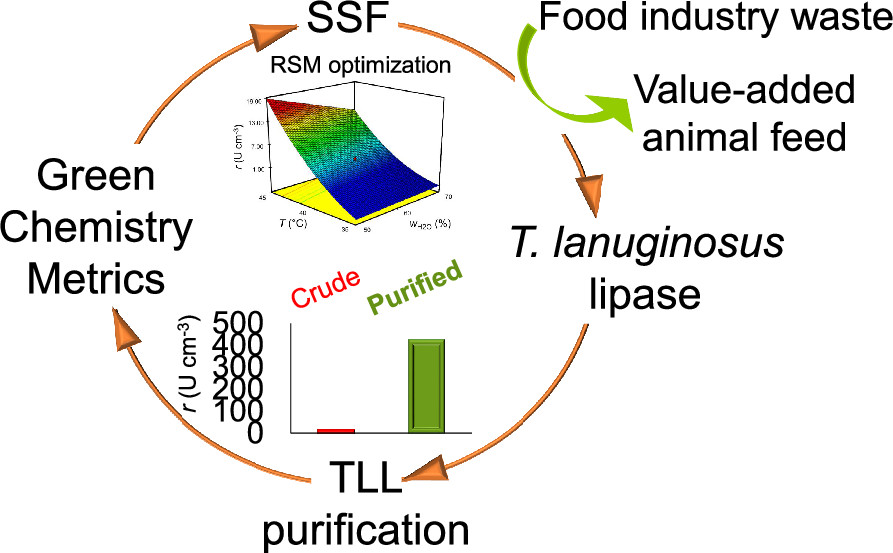

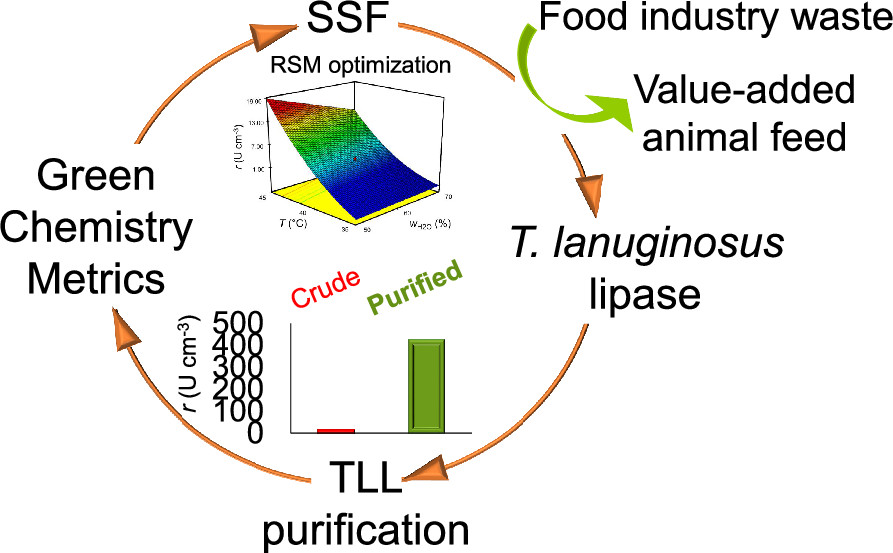

Fig 1. Sustainable production of lipase from thermomyces lanuginosus. (Šibalić D, et al., 2020)

Fig 1. Sustainable production of lipase from thermomyces lanuginosus. (Šibalić D, et al., 2020)

Lipases' utilization in bioethanol production is undoubtedly not as pervasive as in biodiesel. Nevertheless, their importance is growing, especially in the context of lignocellulosic ethanol production, where militant sturdiness is needed to withstand severe physical and chemical conditions. As a result, strategies centered around genetic alterations and protein engineering are being explored to derive lipases that are scientifically suitable for this purpose.

Products and Solutions Offering

Custom Lipases

- Robust, versatile, and tolerant to harsh conditions.

- High specificity and stability in organic solvents.

- Efficient for transesterification reactions.

- Suitable for biodiesel production due to its broad substrate specificity.

- Excellent enantioselectivity for bioethanol and biodiesel synthesis.

Custom Solutions

- Enzyme Engineering: Tailor lipases for optimal performance in specific reactions.

- Immobilization Techniques: Enhance lipase stability and reusability.

- Co-factor Regeneration Systems: Enable cost-effective biofuel production.

- Process Integration: Streamline lipase-based processes for efficiency.

- Enzyme Kinetics Studies: Gain insights into lipase behavior for precise applications.

Services Process for Lipases Design and Optimization

Our lipases design and optimization process comprises several meticulous steps:

1. Sequence Analysis: Employ advanced algorithms to analyze the genetic sequence of lipases to identify potential candidates.

2. Structure Prediction: Utilize advanced computational models to predict the 3D structures of lipases to guide optimization.

3. Catalytic Site Identification: Pinpoint active sites crucial for enzymatic activity.

4. Mutagenesis Design: Leveraging AI algorithms, we engineer mutations for enhanced lipase performance.

5. Virtual Screening: Identify potential lipase candidates for bioethanol and biodiesel applications.

6. Engineering Strategies: Apply molecular modeling techniques for lipase optimization.

7. Functional Characterization: Assess lipase performance via in silico experiments.

Technical Advantages

- Artificial Intelligence (AI) Modeling: Employ AI algorithms for lipase design and prediction.

- Molecular Docking: Simulate interactions between lipases and substrates.

- Protein Engineering: Modify lipase properties to meet biofuel production requirements.

- High-Throughput Screening: Accelerate lipase discovery and optimization.

- Bioinformatics Tools: Analyze lipase sequences and structures for informed decisions.

In the quest for advancements in bioethanol and biodiesel production, CD Biosynsis stands as a pioneering force, offering a comprehensive suite of services and solutions. From lipase design and optimization to the deployment of cutting-edge technologies, we facilitate scientific exploration in this critical field. For further inquiries or to harness the power of AI-driven lipase solutions, please feel free to contact us.

Reference

- Šibalić, D.; et al. Sustainable production of lipase from Thermomyces lanuginosus: process optimization and enzyme characterization. Industrial & Engineering Chemistry Research. 2020, 59(48): 21144-21154.

Fig 1. Sustainable production of lipase from thermomyces lanuginosus. (Šibalić D, et al., 2020)

Fig 1. Sustainable production of lipase from thermomyces lanuginosus. (Šibalić D, et al., 2020)