Our advanced AI-driven enzyme design platform, EnzymoGenius™ specializes in providing comprehensive protease design and optimization services tailored for the saccharification and fermentation processes of lignocellulosic biomass. These services encompass a range of protease products and solutions designed to enhance the efficiency and efficacy of saccharification and fermentation for scientific applications.

Background

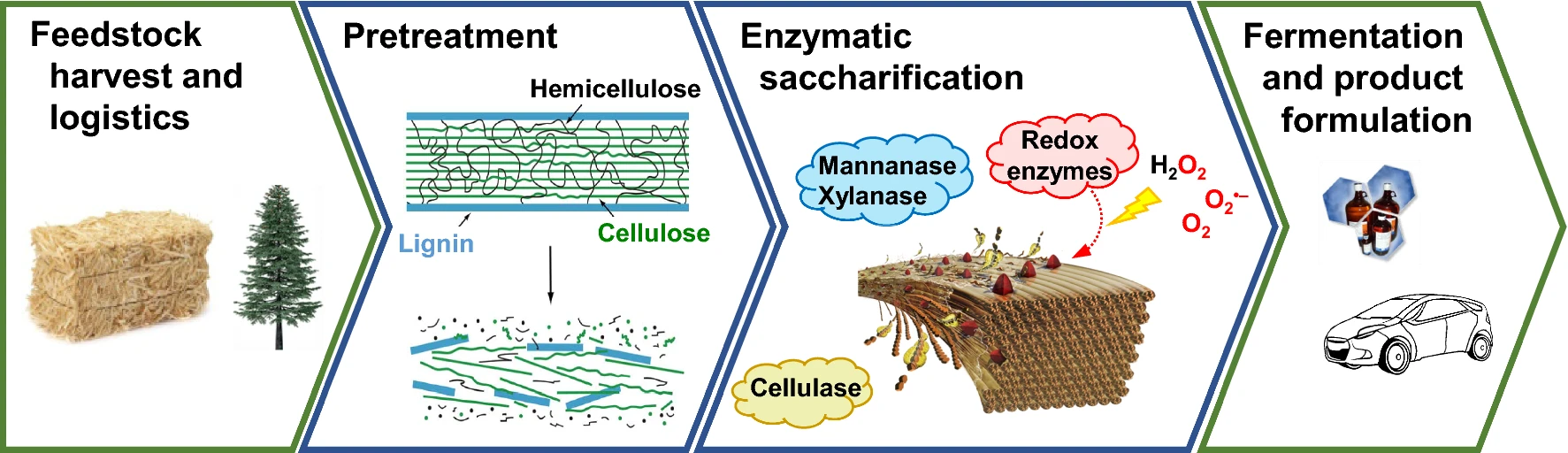

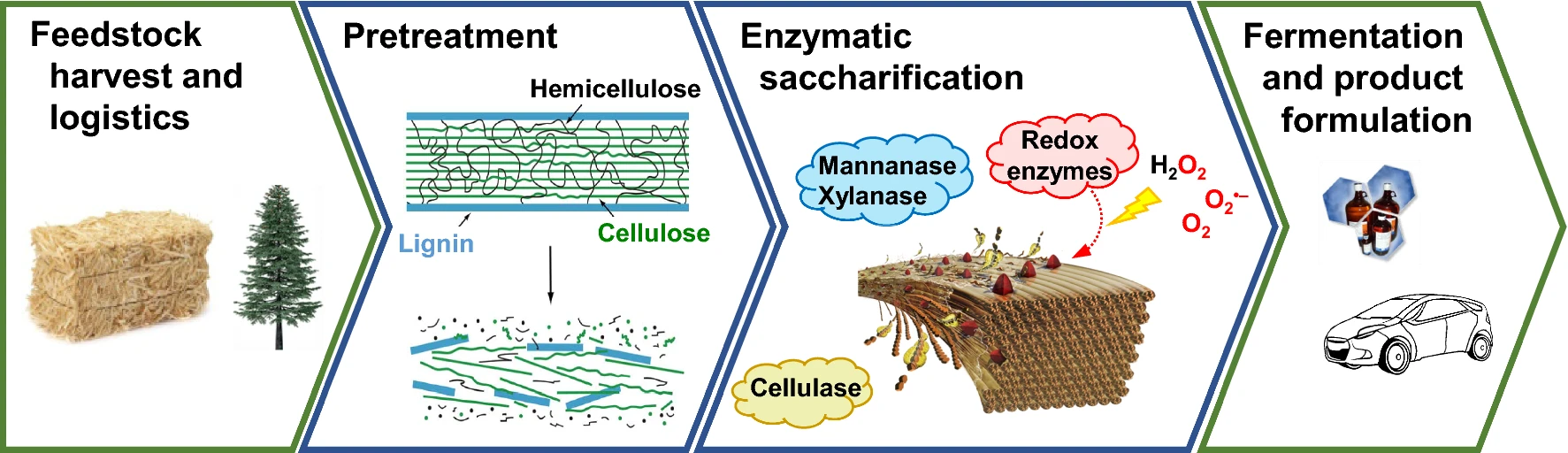

Proteases play a significant role in the saccharification and fermentation of lignocellulosic biomass. Working in synergy with other enzymes, proteases catalyze the hydrolysis of proteins, breaking down complex structures into simple, fermentable sugars. This process contributes to the bioconversion of lignocellulosic waste materials into economically viable, eco-friendly biofuels. Protease design, tailored specifically to optimize this process, is paramount to ensure maximum yield of fermentable sugars, thereby reducing biofuel production costs. Bioengineered protease yield augments substrate accessibility, enhancing hydrolysis rate, and increasing biofuel yield. Furthermore, they exhibit increased stability and efficiency under harsh industrial conditions. Consequently, the implementation of specially designed proteases promises significant advancement in sustainable and cost-effective biofuel production.

Fig 1. Major steps in the conversion of lignocellulosic biomass to ethanol. (Østby H, et al., 2020)

Fig 1. Major steps in the conversion of lignocellulosic biomass to ethanol. (Østby H, et al., 2020)

Solutions and Products Offering

High-quality Protease

- Alkaline Proteases: High pH stability and substrate specificity.

- Acid Proteases: Effective under acidic conditions.

- Thermostable Proteases: Maintains activity at elevated temperatures.

- Substrate-Specific Proteases: Designed for precise cleavage of biomass components.

Custom Solutions

- Enzyme Cocktails: Customized blends for optimized lignocellulosic biomass conversion.

- Pretreatment Enhancements: Protease-based strategies to improve pretreatment efficiency.

- Bioprocess Integration: Incorporating proteases into fermentation workflows for improved yields.

- Scale-Up Consultation: Expert guidance in transitioning protease solutions to industrial scale.

Services for Proteases Design and Optimization

- Target Identification: Identifying specific protease targets within the lignocellulosic biomass.

- Enzyme Engineering: Utilizing advanced techniques to engineer proteases for enhanced substrate specificity.

- Activity Enhancement: Optimizing protease activity through protein modification.

- Process Integration: Integrating proteases into saccharification and fermentation processes seamlessly.

- Performance Evaluation: Rigorous assessment of protease performance in lignocellulosic biomass conversion.

Application in Research

- Biofuel Production: Enhancing saccharification and fermentation for bioethanol and biobutanol.

- Biorefinery Processes: Efficient conversion of lignocellulosic feedstocks into valuable bioproducts.

- Sustainable Agriculture: Enabling the use of biomass for sustainable crop nutrition.

- Environmental Remediation: Facilitating lignocellulosic biomass degradation in environmental applications.

- Cellulose Hydrolysis: Improving enzymatic cellulose degradation for various research purposes.

Technical Advantages

- Molecular Modeling: Employing computational techniques for protease design.

- Directed Evolution: Utilizing genetic engineering to enhance protease properties.

- Protein Engineering: Tailoring proteases for specific lignocellulosic substrates.

- High-Throughput Screening: Rapid assessment of protease variants.

- Fermentation Biotechnology: Integrating proteases into fermentation processes.

In the pursuit of advancing research and innovation in the conversion of lignocellulosic biomass, CD Biosynsis stands as your dedicated partner. With a focus on personalized enzyme design and optimization, our suite of services and solutions caters to diverse applications, from biofuel production to sustainable materials. For inquiries or to explore how our expertise can propel your research forward, please feel free to contact us.

Reference

- Østby, H.; et al. Enzymatic processing of lignocellulosic biomass: principles, recent advances and perspectives. Journal of Industrial Microbiology & Biotechnology: Journal of the Society for Industrial Microbiology and Biotechnology. 2020, 47(9-10): 623-657.

Fig 1. Major steps in the conversion of lignocellulosic biomass to ethanol. (Østby H, et al., 2020)

Fig 1. Major steps in the conversion of lignocellulosic biomass to ethanol. (Østby H, et al., 2020)