Welcome to our advanced enzyme AI design platform - EnzymoGenius™, which offers comprehensive solutions for the food and beverage processing sector. By customizing rennet, we support our customers in optimizing all processes of dairy production. Our services are designed to optimize efficiency, quality, and overall production in the dairy industry.

Role of Rennet in Dairy Processing

Rennet (a mixture of chymosin and pepsin obtained mainly from animal and microbial sources), also known as rennin, is mainly used to coagulate cow's milk, goat's milk, and other mammalian milk products for the preparation of cheese and other dairy products. This enzymatic action is vital for curd formation and whey separation. Rennet is mainly used for hard cheeses and rarely for soft cottage cheese or cheese.

- Curd Formation: Rennet works by specifically cleaving the κ-casein fraction, causing it to come together and form a solid curd while releasing the whey. This process, called curdling, is one of the central steps in cheese preparation. It effectively separates the liquid whey from the solid curd, minimizing waste and increasing cheese yield.

- Improved Texture and Flavor: Beyond its curdling prowess, rennet exerts a profound impact on the cheese's ultimate texture, flavor, and overall quality. It exerts a subtle yet masterful influence over the size and architecture of curd particles, and in the course of aging, it governs the gradual release of flavor compounds.

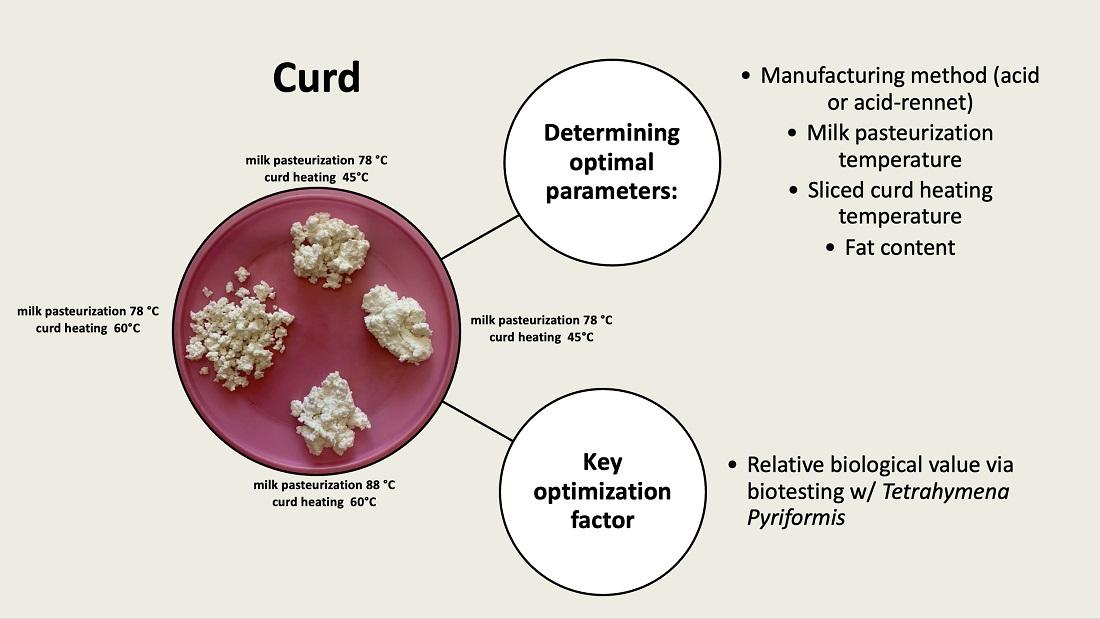

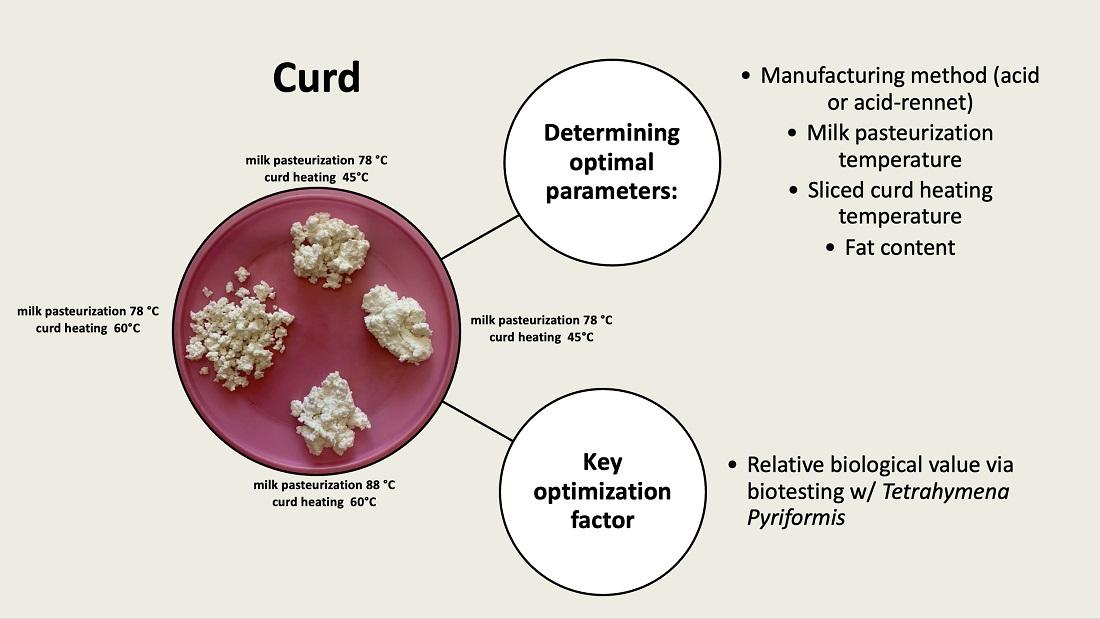

Fig. 1 Curd formulation and manufacturing process design based on express biological evaluation tests. (Zobkova Z S, et al., 2022)

Fig. 1 Curd formulation and manufacturing process design based on express biological evaluation tests. (Zobkova Z S, et al., 2022)

Research Trends in Rennet for Dairy Processing

The use of rennet in the dairy industry has a long history, but researchers have been exploring different aspects of rennet applications and alternatives as technology advances and consumer needs change. Currently, in order to improve cheese quality as well as address sustainability and cost-effectiveness issues in the dairy industry, research trends focus on the following areas:

- Improvement of enzymes through genetic engineering to optimize enzyme parameters, such as temperature and pH.

- Production of alternative rennet enzymes through microbial fermentation processes to reduce dependence on animals.

Products and Solutions Offering

High-quality Rennet

Our engineered rennet has a number of excellent properties, including:

- Substrate Specificity: Highly specific in cleaving kappa-casein in milk, forms curd during coagulation.

- Temperature Sensitivity: Operating optimally within a specific temperature range, Chymosin allows precise control during processing.

- pH Sensitivity: The enzyme's effectiveness is pH-dependent, making it crucial to maintain the correct pH for successful milk coagulation.

Custom Rennet-based Solutions

- Milk Coagulation Enhancement: Rennet-based solutions power up milk coagulation, ensuring swifter, more efficient cheese production.

- Whey Protein Separation: Helps to separate whey proteins to produce high quality whey protein powders.

- Cheese Production: for milk coagulation and to facilitate the preparation of cheese.

- Yogurt and Fermented Dairy Products: helps to improve the taste and texture of yogurt and fermented dairy products.

- Dairy Stability: improves the stability of dairy products, extends shelf life and reduces texture changes.

- Lactose Reduction: For reducing the lactose content in dairy products to meet the needs of different consumers.

Services Process for Rennet Design and Optimization

1. Clarify Requirements & Data Collection: Define the properties of the rennet to be optimized and collect data, including enzyme structural, activity, substrate properties, reaction conditions, etc.

2. Algorithmic Analysis: Utilize advanced algorithms to optimize the chymosin formulation, dosage, and process parameters.

3. Simulation and Modeling: Create digital simulations and models to predict the results of different chymosin-based processes.

4. Optimization: The AI model will generate a design of the rennet enzyme with the desired properties. This can include the desired sequence of the enzyme to improve its performance.

5. Monitoring and Feedback: Continuously monitor and fine-tune the process based on real-time data and customer feedback for ongoing optimization.

Competitive Advantages

- Artificial Intelligence: Our platform leverages AI for enzyme design, using deep learning models to create tailored solutions.

- Enzyme Engineering Technology: Support in-depth studies of enzyme structure and function to target improvements.

- Bioinformatics: Our technology allows for the collection, processing and analysis of large amounts of data. This data-driven approach helps to better understand enzyme properties and reaction processes.

- Simulation Tools: Simulation tools are used to evaluate the performance of the designed enzyme in an actual production environment. This helps predict enzyme stability and reliability and reduces the need for experimentation and laboratory testing.

- Molecular Biology: Our design process incorporates knowledge of enzyme structure and function to create highly effective enzyme variants.

CD Biosynsis, with a focus on precision and innovation, offers AI-driven enzyme-based solutions tailored to your specific needs. Our expertise spanning food baking, brewing, dairy processing, vegetable and fruit processing, value-added by-products, and food ingredient development, among others, is at your disposal. Leveraging the synergy of AI and synthetic biology, we provide unmatched advantages, elevating both productivity and product quality. To explore potential possibilities in food and beverage development or for inquiries, please don't hesitate to contact us.

Reference

- Zobkova, Z.S.; et al. Modification of biotesting-based fermented dairy product design for curd and curd products. Foods. 2022, 11(20): 3166.

Fig. 1 Curd formulation and manufacturing process design based on express biological evaluation tests. (Zobkova Z S, et al., 2022)

Fig. 1 Curd formulation and manufacturing process design based on express biological evaluation tests. (Zobkova Z S, et al., 2022)