Welcome to our advanced enzyme AI design platform - EnzymoGenius™, where we cater to the specific needs of the food and beverage processing sector, offering a wide range of tailored solutions. In the field of brewing processing, our expertise lies in providing custom-designed α-amylase-based solutions. We leverage cutting-edge technologies to deliver enzymatic solutions that optimize various stages of brewing, thereby empowering our clients to achieve exceptional results.

The Role of Xylanase in the Brewing Process

Xylanase plays a crucial role in diverse industrial processes: juice extraction, feed digestion, bio-bleaching, and dough characterization. In the brewing process, especially during saccharification and filtration, it assumes a pivotal role. The plant cell wall, a three-dimensional complex network predominantly comprising lignocellulose, features xylan as its primary component. In brewing, xylanase catalyzes the conversion of intricate xylan in plant materials like barley and wheat into simpler compounds like xylose. This catalysis optimizes the utilization of sugars and proteins, enhancing the fermentability of the wort and beer quality. Simultaneously, it aids wort filtration by diminishing viscosity, ensuring a clearer end product.

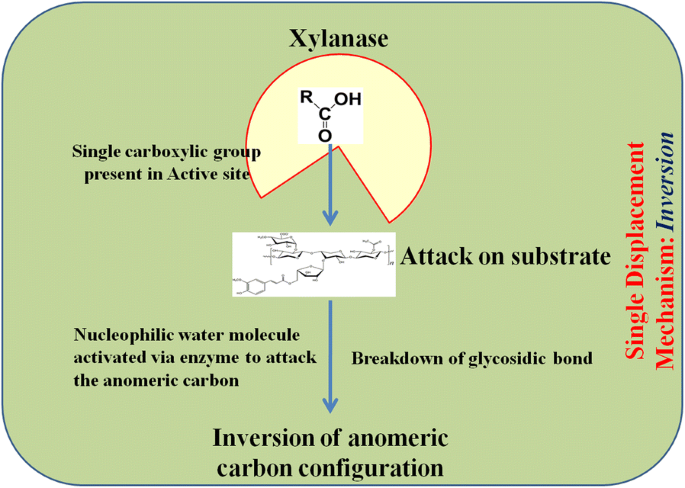

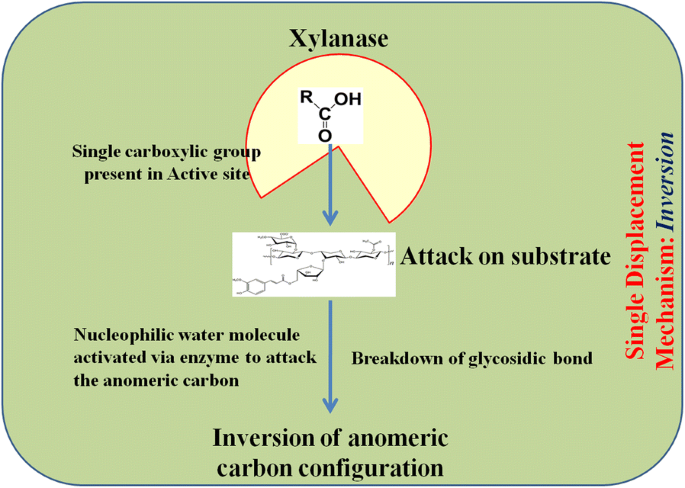

Fig. 1 Mode of action of xylanase: inversion. (Bhardwaj N, et al., 2019)

Fig. 1 Mode of action of xylanase: inversion. (Bhardwaj N, et al., 2019)

Xylans, with their compositional diversity, necessitate a spectrum of enzymes for degradation, notably endo-xylanase and β-xylosidase. The catalytic action of these enzymes revolves around cleaving β-1,4-D-xylosidic linkages in xylans, liberating xylo-oligosaccharides crucial for yeast metabolism in fermentation. The enzymatic hydrolysis stage, the costliest in fermentation, involves expensive and scarce enzymes. Research trends now focus on enhancing xylanase efficiency and specificity to suit varied brewing processes. Genetic engineering is being explored for tailor-made xylanases to amplify performance. In essence, xylanase remains integral to brewing, with ongoing research dedicated to refining applications and maximizing its impact on the brewing process.

Products and Solutions Offering

High-quality Xylanase

- Temperature Tolerance: Optimal activity in a specific temperature range.

- pH Sensitivity: Activity is pH-dependent, allowing for fine-tuning of enzyme action at different brewing stages.

- Substrate Specificity: Highly selective enzymes target hemicellulose.

Custom Xylanase-based Solutions

Our cutting-edge technology and experience support the design and optimization of xylanase properties for the different stages of brewing, tailoring solutions to the specific needs of different customers, committed to meeting their expectations for the release of flavor compounds during the brewing process and the sensory profile of the brewed product.

- Improved wort separation and higher extract yields at the saccharification stage.

- At the fermentation stage, it helps to reduce viscosity and increase the utilization of sugars by the yeast, thus improving fermentation efficiency and alcohol yield.

- Promotes the breakdown of polysaccharides during filtration and clarification, resulting in clearer beer and improved filtration performance.

Services Process for Xylanase Design and Optimization

1. Data Collection: The process begins with the collection of comprehensive data related to the brewing process, including raw materials, environmental conditions, and desired outcomes.

2. Algorithmic Analysis: Advanced AI algorithms dive into this data to pinpoint opportunities for xylanase intervention and optimization.

3. Enzyme Engineering: Informed by algorithmic revelations, we meticulously engineer and refine xylanases to realize the brewing goals, be it enhanced efficiency, flavor, or clarity.

4. Testing and Validation: The engineered xylanases undergo rigorous testing under simulated brewing conditions to guarantee both effectiveness and safety.

Technical Advantages

- Molecular Biology: Our design process integrates enzyme structure and function knowledge, yielding remarkably efficient enzyme variants.

- Artificial Intelligence: Harnessing the power of artificial intelligence, our platform crafts custom solutions through deep learning models.

- Computational Modeling: Employing advanced modeling techniques, we simulate enzymatic reactions to fine-tune and enhance performance.

- Bioprocess Engineering: We apply engineering principles to scale up and implement our enzyme solutions in large-scale brewing operations.

- Bioinformatics: Data analysis and bioinformatics tools gather and interpret information relevant to enzyme design and optimization.

CD Biosynsis, backed by a professional scientific team, is committed to furnishing researchers with enzyme-directed evolution and design services. Our expertise spans the entirety of the food and beverage processing spectrum: food baking, brewing, dairy processing, vegetable and fruit processing, value-added by-products, and food ingredient development. Leveraging AI and synthetic biology synergies, we deliver unparalleled advantages for heightened productivity and superior product quality. For those intrigued by exclusive, tailored enzyme services, don't hesitate to reach out to us.

Reference

- Bhardwaj, N.; et al. A detailed overview of xylanases: an emerging biomolecule for current and future prospective. Bioresources and Bioprocessing. 2019, 6(1).

Fig. 1 Mode of action of xylanase: inversion. (Bhardwaj N, et al., 2019)

Fig. 1 Mode of action of xylanase: inversion. (Bhardwaj N, et al., 2019)