EnzymoGenius™ is our state-of-the-art enzyme AI design platform. With a professional team of scientists, we have long been dedicated to providing researchers with targeted enzyme evolution and design services. For the food and beverage processing sector, especially for carbohydrate processing, we offer customized xylanase solutions designed to enhance various key steps in carbohydrate processing, ensuring efficiency and precision.

Role of Xylanase in Carbohydrate Processing

Xylanase, a pivotal enzyme in food carbohydrate processing, crucially degrades hemicellulose—complex plant cell wall carbohydrate. Cleaving β-1,4-xylosidic linkages, it releases xylose units and oligosaccharides. This depolymerization is fundamental in producing diverse food products, notably in baking and brewing. Xylanase enhances dough rheology, boosting gas retention and bread volume. Moreover, it aids in degrading non-starch polysaccharides in animal feed, fostering nutrient absorption and livestock growth.

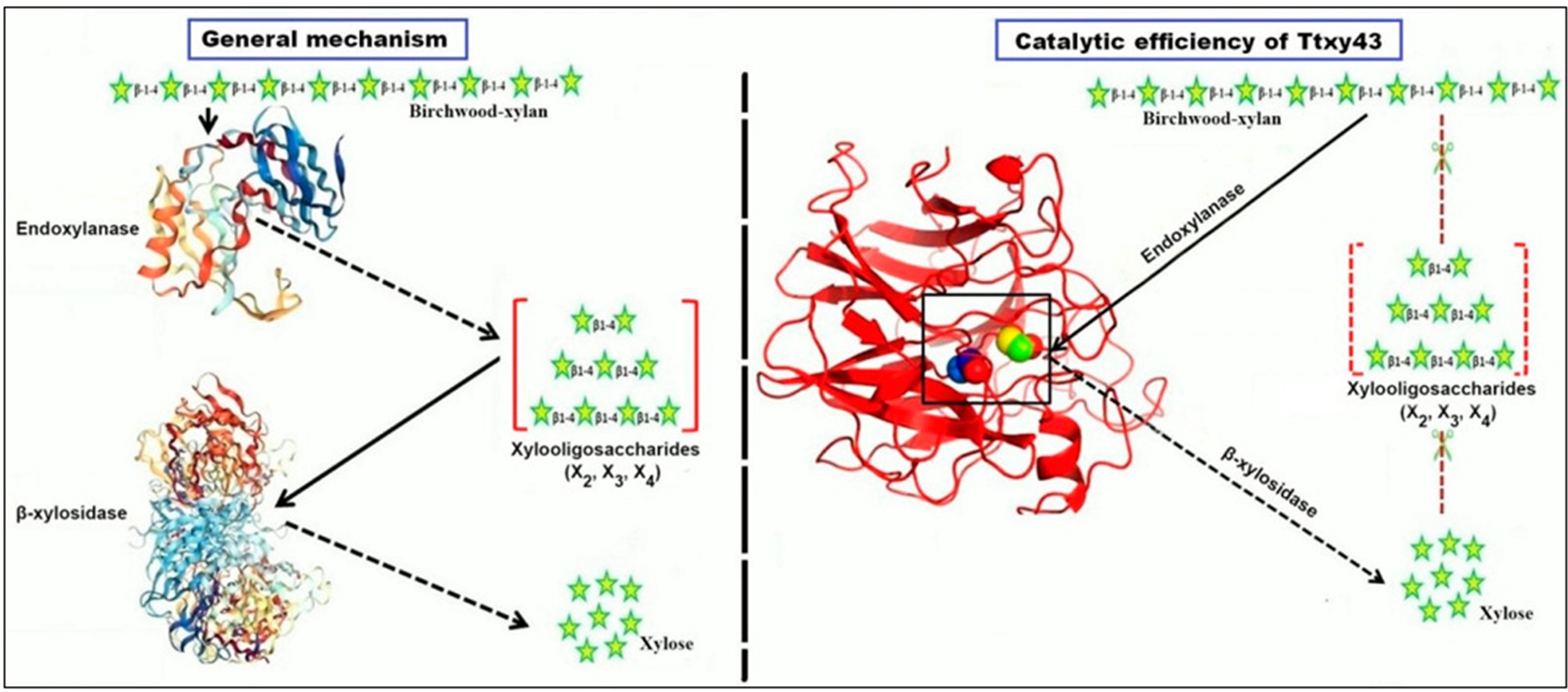

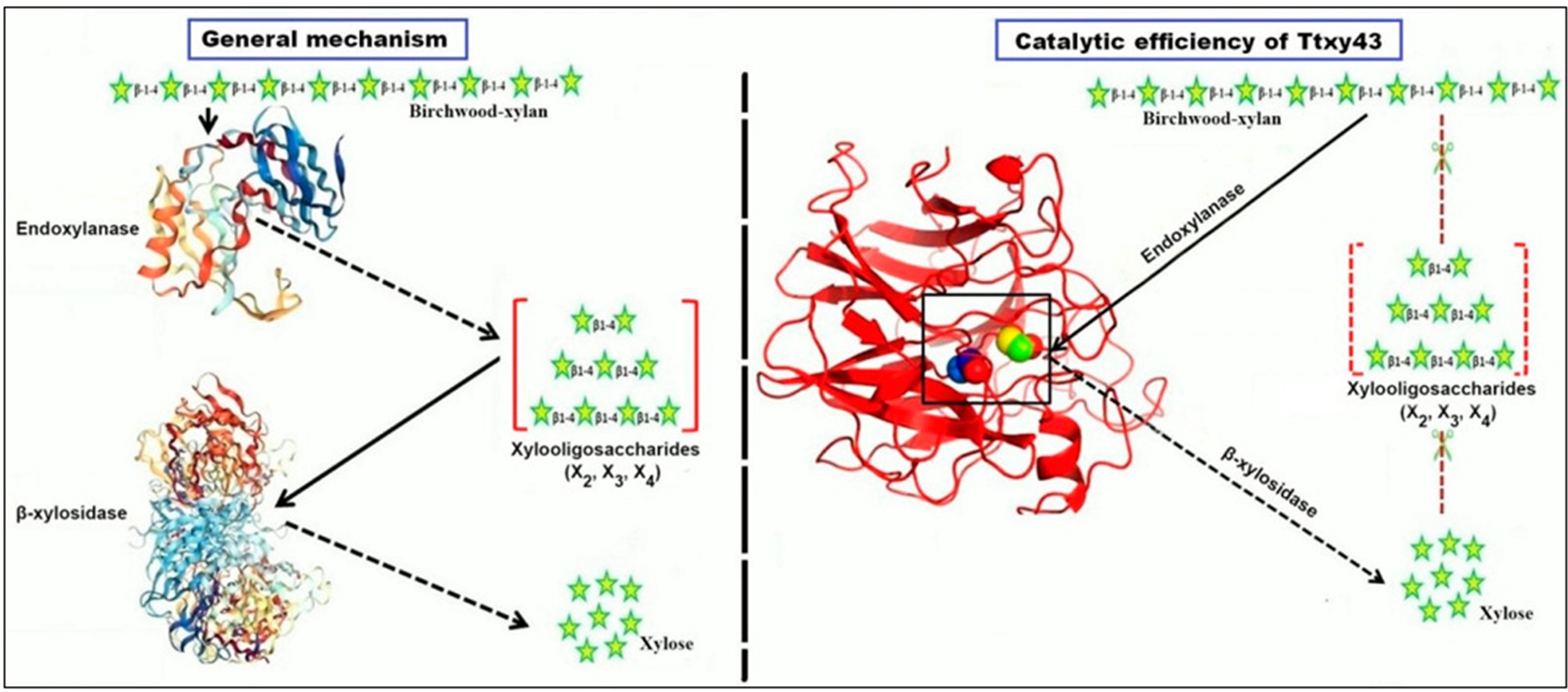

Fig. 1 Xylan is efficiently enzymatically cleaved to xylose. (Abdul B, et al., 2019)

Fig. 1 Xylan is efficiently enzymatically cleaved to xylose. (Abdul B, et al., 2019)

Recent trends in xylanase application research center on enzyme engineering, aiming to optimize catalytic efficiency and thermal stability. This enhances functionality across diverse food processing conditions. Simultaneously, there's a rising interest in xylanase as a tool for modifying food product texture and sensory attributes. This exploration carries implications for crafting healthier, fiber-enriched alternatives. The versatility and utility of xylanase in food processing underscore its pivotal role in meeting the evolving demands of the food industry.

Products and Solutions Offering

High-quality Xylanase

We deliver xylanases that are adapted to a variety of industrial environments, minimizing unwanted side reactions and ensuring maximum substrate conversion and process yields.

- Thermal Stability: Demonstrates stability and activity over a wide range of temperatures.

- pH Range: Our xylanases are effective over a wide pH range.

- Substrate Specificity: Highly specific for xylan substrates.

- Enzyme Efficiency: Exceptional catalytic efficiency.

Custom Cellulase-based Solutions

Xylanase-based solutions can be customized at different stages of carbohydrate processing, contributing to the enhancement of flavor and texture of the final food product.

- Pre-Treatment: Xylanase solution for pretreatment processes of carbohydrate raw materials. Facilitates the breakdown of hemicellulose in plant cell walls, increasing the efficiency of subsequent extraction and fermentation steps.

- Extraction: Customized xylanase solutions during the extraction process promote hemicellulose breakdown, releasing more valuable soluble carbohydrates.

- Fermentation: Converts complex hemicelluloses into simple sugars that are more readily metabolized by microorganisms, thereby improving the fermentability of carbohydrates.

- Saccharification: Xylanase solutions to hydrolyze xylan to produce xylose.

- Product Quality Enhancement: Customized solutions are used to modify the properties of carbohydrates, such as reducing viscosity.

Services Process for Xylanase Design and Optimization

1. Project Consultation: Initiate by defining project goals and requirements.

2. Data Collection: Our platform gathers comprehensive data on the carbohydrate processing requirements and specific substrates.

3. AI Design: Utilizing advanced algorithms, our AI designs tailored xylanase enzymes optimized for the specific application.

4. Enzyme Development: The selected xylanase sequences are synthesized and subjected to rigorous testing for performance and stability.

5. Integration: The optimized xylanase is seamlessly integrated into the existing processing pipeline.

6. Continuous Monitoring: Our platform continuously monitors the enzymatic performance, making real-time adjustments for maximum efficiency.

7. Reporting and Optimization: We provide detailed reports and offer further optimization options based on evolving requirements.

Technical Advantages

- Cutting-edge Artificial Intelligence (AI).

Design and optimization of xylanase for baked goods processing.

- Advanced Molecular Biology Techniques.

Including gene synthesis and cloning for enzyme production.

- High-Throughput Screening Tools.

Facilitate the rapid assessment of enzyme variants, accelerating the optimization process.

- Analytical Chemistry Techniques.

Such as mass spectrometry and chromatography for enzyme characterization and food product analysis.

- Computational Modeling.

Simulate enzyme-substrate interactions and predict optimal conditions.

With a professional scientific team, CD Biosynsis has been dedicated to providing researchers with enzyme directed evolution and design services. Our services cover the entire food and beverage processing spectrum, including food baking, brewing, dairy processing, vegetable and fruit processing, value-added by-products, and food ingredient development. Through the combined power of AI and synthetic biology, we can offer unrivaled advantages to improve productivity and product quality. If you are interested in the exclusive customized services for enzymes, please feel free to contact us.

Reference

- Abdul, B.; et al. Highly efficient degradation of xylan into xylose by a single enzyme. ACS Sustainable Chem. Eng. 2019, 7(13): 11360–11368.

Fig. 1 Xylan is efficiently enzymatically cleaved to xylose. (Abdul B, et al., 2019)

Fig. 1 Xylan is efficiently enzymatically cleaved to xylose. (Abdul B, et al., 2019)