In the biopharmaceutical process, cell lines play a crucial role as a marker for the activation of CMC. A good cell line can not only reduce the difficulty of CMC development, but also greatly reduce the cost of drug development. However, the development of cell lines is a long and complex process, with multiple stages determining the quality of the final cell line. What are the steps that major companies use to control the development of cell lines? Recently, a cell line team from BioPhorum has conducted statistical surveys on multiple pharmaceutical companies (Seagen, Bayer, Sanofi, Abbott, Pfizer, Merck, GSK, BI, Johnson&Johnson, etc.), so that we can have a comprehensive understanding of the development of cell lines.

This statistical survey contains 341 questions and divides the development of cell lines into three modules: 1) pre transfection preparation, including vector design and construction; 2) Transfection: mainly includes transfecting DNA into cells and subsequent screening and pool analysis; 3) The selection of monoclonization and Top cell lines mainly includes the sorting method of monoclons, confirmation of clones, screening of clones, expansion of culture, and selection of final cell lines.

Firstly, let’s take a look at the size of the cell line teams of companies. Among the pharmaceutical companies surveyed, about one-third had 1-5 members, one-third had 5-10 members, and the remaining one-third had more than 10 members.

1.Preparation before transfection

Before the construction of the cell line begins, some preparatory work needs to be done, including drug resistance evaluation, plasmid design, target gene synthesis, plasmid construction, plasmid quality testing, and host cell preparation. In terms of drug efficacy evaluation, whether it is monoclonal antibodies or complex molecules (dual antibodies, fusion proteins, etc.), most companies still prefer to complete the evaluation internally. In addition, host cell and plasmid preparation are mostly completed internally; For the synthesis of target genes, almost all companies choose external synthesis, mainly because external synthesis is more efficient and economical. However, for plasmid design, plasmid extraction, and quality identification, both external and internal processes account for about half of the work. In plasmid construction, over 90% of companies choose to place light and heavy chains on the same plasmid for monoclonal antibodies, while for complex antibodies or other drugs, most choose to place them on multiple plasmids or depending on the project (see Figure b).

In terms of cycle, most preparations before electric rotation are between 4-6 weeks, with some exceeding 7 weeks, but generally not more than 8 weeks. Of course, there are basically no preparations less than or equal to 3 weeks. This is mainly because gene synthesis and vector construction require a certain amount of time.

In terms of developing molecular quantity, for monoclonal antibodies or complex drugs, most projects will develop 2-5 different molecules. Of course, for monoclonal antibodies, companies that only develop one molecule still account for a considerable proportion.

The number of molecules developed for each monoclonal antibody project

The number of molecules developed for each monoclonal antibody project

The number of molecules developed for each complex project

The number of molecules developed for each complex project

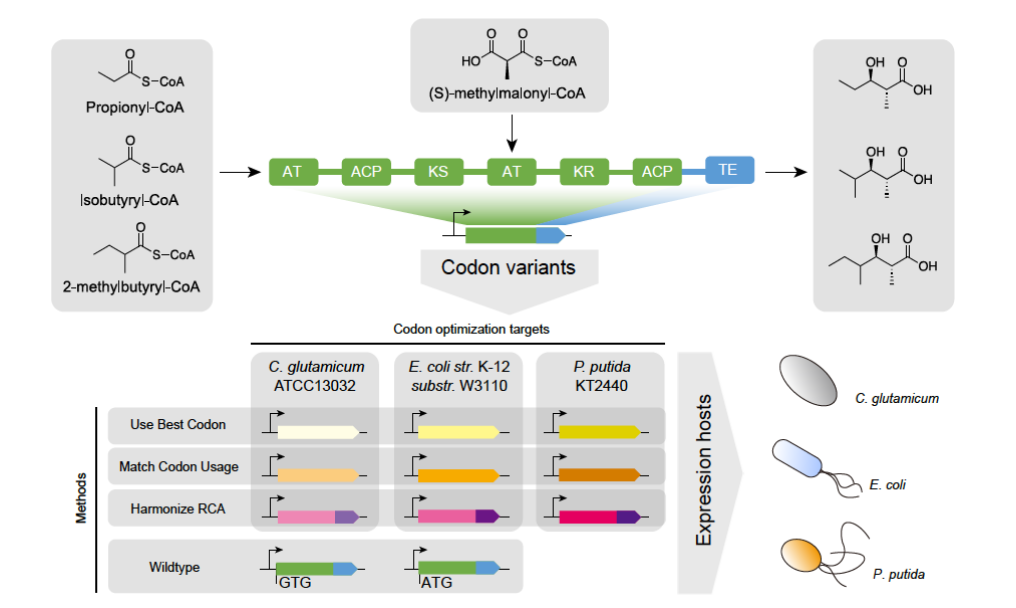

In terms of the number of sequences developed for each molecule (encoding the same amino acid but different DNA sequences) (mainly including signal peptides, codon optimization, etc.), for simple monoclonal antibodies, more than 50% of companies basically only develop one sequence, and a considerable proportion of companies develop two different sequences, with a few companies developing 3-5 different sequences. However, for complex drugs, the proportion of the above three situations is equivalent, mainly because for complex drugs, the sequence may be more complex and requires some exploration and research.

Monoclonal antibody project

Monoclonal antibody project

Complex projects

Complex projects

Whether the plasmid is consistent with research and development: Whether it is a simple monoclonal antibody or a complex drug, the vast majority of company cell lines have inconsistent plasmids and research and development, mainly due to different purposes in the two stages. The research and development stage is to quickly obtain proteins, so antibody design is quite simple to increase antibody expression. However, cell lines need to add more elements to the vector, on the one hand to increase antibody expression, and on the other hand to maintain gene stability.

Monoclonal antibody project

Monoclonal antibody project

Complex projects

Complex projects

Host cell preparation: The quality of host cells is also crucial for the construction of cell lines. If the host cells are passaged for a long time before transfection, cell viability may decrease, and the genome may undergo recombination mutations. Therefore, theoretically, it can affect transfection efficiency or affect protein expression or post-translational modifications within the cell. Most companies will control the passage of host cells within 30 generations, and more strictly within 10 generations.

Monoclonal antibody project

Monoclonal antibody project

Complex projects

Complex projects

Related Services

Plasmid DNA Preparation Service

Modified DNA Synthesis Service

2.Transfection&Screening

The different screening methods after transfection determine the cycle and workload of cell line development. Firstly, for screening methods, the commonly used ones are MSX based on the glutamine system, antibiotics, and screening based on influence defects. MTX based on the dihydrofolate reductase system is currently relatively less commonly used (see Figure a);

Before completing the preliminary screening and entering the monoclonal screening stage, most companies only examine the growth of the pool and the expression based on the shrinking model. Moreover, when the pool enters the sorting monoclonal stage (as shown in the figure below), for complex drugs, most companies will parallel examine the quality of the target protein expressed in the pool (as shown in figure c);

The screening cycle required to switch from electric to bulk pool: whether it is monoclonal antibodies or complex drugs, the two cycles are basically the same, most of which take 3-4 weeks. If it is fast, it takes 1-2 weeks to complete, but there are also some that exceed 5 weeks (as shown in Figure d);

Transfection method: Whether it is monoclonal antibodies or complex drugs, the vast majority of them are currently electroporated in industry, with a few using liposome transfection.

The number of transfected pools per molecule: Whether for monoclonal antibodies or complex drugs, most companies will transfect multiple pools of 4 or more during transfection, because under the same transfection conditions, different pools may have different expression and quality.

Monoclonal antibody project

Complex projects

Complex projects

Additional factors for transfection investigation: The host’s expression of target proteins is influenced by various factors, such as plasmid combinations, plasmid skeletons, codons, signal peptides, transfection methods, sequential transfection, etc. (Complex drugs and monoclonal antibodies have the same type, but different proportions, but they are basically the main factors to be investigated).

Plasmid transfection ratio: For monoclonal antibodies, because some companies use light and heavy chain separation, about one-third of the transfection ratio is 1:1, and most still use different ratios or different ratios depending on the project; For complex drug expression, it is actually similar to monoclonal antibodies.

Monoclonal antibody project

Monoclonal antibody project

Complex projects

Complex projects

Pre screening cell recovery time: After transfection, especially for electroporation, the cells are in a relatively fragile state, and even if gene transfection enters the cells, they will not be able to express themselves. Therefore, it is generally necessary to allow the cells to recover for a period of time before adding screening drugs for screening, which usually takes 1-2 days, and about 1/4 of companies will take more than two days. The difference between monoclonal antibodies and complex drugs is not significant.

Monoclonal antibody project

Complex projects

Complex projects

Screening the types of Pools: Different Pools not only affect expression levels, but also are related to cell diversity. Minipool has a relatively high expression level, but its diversity is low. The expression level of bulk pool is relatively low, but the diversity of cells is more abundant, and the types of monoclonal screening in the later stage are more diverse. Most biopharmaceutical companies still use bulk pool for screening, and for safety reasons, some companies also adopt a strategy of bulk pool and minipool.

Monoclonal antibody project

Monoclonal antibody project

Complex projects

Complex projects

Pool screening cycle: Whether it is monoclonal antibodies or complex drugs, pool screening generally takes 2-3 weeks, but for complex projects, the proportion of 4-5 screening cycles is increased.

Monoclonal antibody project

Monoclonal antibody project

Complex projects

How many pools are selected for monoclonal sorting for each molecule: Different pools may have different expression levels and qualities. In order to improve the diversity of monoclonal antibodies, multiple pools are usually selected for subsequent sorting. For monoclonal antibodies, companies often choose 4 or more pools for monoclonal sorting, while for complex drugs, similar to monoclonal antibodies, most choose 4 or more pools for monoclonal sorting.

Monoclonal antibody project

Monoclonal antibody project

Complex projects

Complex projects

How many molecules enter the monoclonal sorting stage for each project: For monoclonal antibody drugs, most companies will choose the final molecule to enter the monoclonal sorting stage. However, we have also found that some companies will choose two or four or more molecules for the monoclonal sorting stage. However, for complex drugs, almost all companies choose a molecule to enter the monoclonal sorting stage. This may be because complex drugs may have complex structures, and researchers usually conduct sufficient research before development, including drug efficacy, drug properties, etc. Therefore, they choose the molecule with the best comprehensive performance from all aspects to enter the monoclonal sorting stage.

Monoclonal antibody project

Monoclonal antibody project

Complex projects

3.Monoclonal sorting and screening

The selection of monoclonal antibodies is the most time-consuming and crucial stage in the development of cell lines. A good monoclonal cell line should not only have high expression levels, but also good quality. In countries, the sorting of monoclonal antibodies presents diversity, and the most common methods are FACS (flow cytometry), single-cell printers, and Beacon, which can effectively sort individual cells (as shown in Figure a). In terms of proving the source of monoclonal antibodies, the commonly used instruments currently include Beacon, Cellavista, Clone Select Image, and Cell Metric (Figure b).

In terms of monoclonal recovery rate (when a single cell grows into a colony), although monoclonal antibodies differ from complex drugs, most of them are still between 30% and 80%. Of course, some companies have relatively low clone recovery rates of only 10% -20% due to method reasons (Figure c). The use of instruments to determine the source of monoclonal antibodies is also a very important step in the development of cell lines. In monoclonal screening, it is necessary to check the source of monoclonal antibodies. Among the companies participating in the investigation, some companies will ultimately check the number of clones with source of monoclonal antibodies less than 10, while most will check the source of monoclonal antibodies for more than 50 clones.

Monoclonal screening cycle: It generally takes a long time from monoclonal sorting to the determination of candidate clones. For relatively simple monoclonal antibodies, it usually takes 17-20 weeks. However, if it is fast, some companies can determine the final candidate cell line within 4-8 weeks. The different cycles mainly depend on the equipment and technical route used by the company. For complex drugs, multiple dimensions are required to evaluate cell lines, so most companies require more than 13 weeks.

Monoclonal antibody project

Monoclonal antibody project

Complex projects

Complex projects

What are the processes required from single-cell sorting to candidate clone confirmation? In this regard, both types of drugs are basically the same, including 96/24 deep well plate culture, shake flask, tube or reactor culture, clone stability, gene level identification, quality, and RCB establishment. Of course, not all of these processes may be used for the final screening of monoclonal antibodies, mainly related to the company’s platform and technological roadmap.

Monoclonal antibody project

Monoclonal antibody project

Complex projects

Complex projects

From single cell to first cryopreservation cycle: Cells need different times from being divided into individual cells to growing to a certain size, which is mainly related to host cells, technological routes, etc. Whether it’s monoclonal antibodies or complex drugs, most companies are concentrated between 4 and 11 weeks.

Monoclonal antibody project

Monoclonal antibody project

Complex projects

Complex projects

The types of monoclonal sorting well plates: Different types of well plates have differences in sorting flux. Currently, whether it is monoclonal antibodies or complex drugs, most companies choose to sort individual cells into 96 well plates. In addition, some companies choose to sort into 384 well plates. Of course, there are also some companies that choose relatively niche nanopores or nano pens (after checking, I couldn’t find what they look like, friends who know can send a private message).

Monoclonal antibody project

Monoclonal antibody project

Complex projects

Complex projects

The number of monoclonal sorting: In China, 96 well plates are usually used for monoclonal sorting, so it is generally said how many plates are laid. In countries, because more well plates are used, the number of wells is counted. From the figure below, it can be seen that for the two types of drugs, most companies sort fewer than 1000 monoclonal wells or between 1000-2000, and of course, some companies sort more than 10000 wells.

Monoclonal antibody project

Monoclonal antibody project

Complex projects

Complex projects

Whether to distinguish cell expression levels during the sorting process: In the pool stage, especially bulk pool, due to the rich diversity of cells, there may be some cells with lower expression levels. Therefore, if low expression cells can be excluded during the screening stage, it can increase the probability of screening high expression cell lines and also improve efficiency, such as studying antibody staining on the surface of cell membranes. Nearly half of companies will sort highly expressed cells during the monoclonal sorting stage.

Photo time: Due to regulatory requirements to prove that the cell line originates from a single cell, and the image is a direct evidence, it is also quite efficient, but requires special instruments. The conventional limited dilution method requires two rounds and additional experimental proof. Therefore, currently, most companies use instruments that can improve the image to prove the monoclonal origin of the cell line. In terms of photography strategy, different companies have different choices, but almost all companies will take photos on the day of sorting to prove that the candidate cells come from a single cell.

How many people are needed to view the source of a single clone: Currently, confirmation of the source of a single clone mainly relies on images, so it needs to be viewed individually. To ensure the accuracy of the source of a single clone, most companies choose two people to view and confirm it simultaneously. Some companies also choose three or more people to view it, while others only require confirmation by a single person.

What are the indicators to focus on when transitioning from static culture to suspension culture? As is well known, after monoclonal sorting, static culture is basically carried out in a well plate. After a certain scale or screening, suspension culture needs to be carried out in a shaking bottle. So, what indicators are usually screened during this process? Most companies focus on cell growth and expression, with a few companies focusing on the quality of target proteins expressed in cells.

Automation: There are multiple steps in the process of cell line monoclonal screening, which ones are easier to automate? Firstly, monoclonal sorting and photography. Currently, most companies have achieved automation, mainly due to the emergence of advanced instruments replacing traditional limited dilution methods. Next is the selection and expansion of monoclonal antibodies, which mainly involves the development and use of liquid workstations. Then comes the expression and detection of monoclonal antibodies, which mainly involves the collaboration between multiple instruments, such as the addition of robotic arms, making it possible. Of course, with the advancement of technology, the integration of multiple processes may become possible.

What are the components of clone culture medium? Monoclonal cells are relatively difficult to grow, so special components are often added to promote cell growth during clone selection. Common components include growth factors and conditional culture medium. Of course, some companies also add screening pressure during the cloning process (not recommended).

Pre RCB cryopreservation quantity: Before the final PCB decision, monoclonal cells are usually subjected to initial screening for cell cryopreservation backup. Subsequently, PCBs will be selected for cryopreservation based on growth, expression, quality, etc. Whether it is monoclonal antibodies or complex drugs, most companies will choose to freeze more than 40 monoclonal clones, while a few companies only freeze up to 10 monoclonal clones.

Monoclonal antibody project

Monoclonal antibody project

Complex projects

Complex projects

Summary

This survey report provides a comprehensive analysis of the cell line development strategies of major companies, including preparation before cell line screening, transfection screening, and final monoclonal screening. For non cell line practitioners, a comprehensive understanding of cell line development work can also be obtained from investigation reports.