Microtiter Plate Screening (MSP) Technology

- Home

- EnzymoGenius™ Technology

- Microtiter Plate Screening (MSP) Technology

Our company is committed to providing customers with high-quality Microtiter Plate Screening (MSP) technology. Microplate Screening Technology (MSP) is an efficient and accurate screening method that is widely used in the fields of biochemistry, drug development, and enzymology research. By using microplates, a large number of parallel experiments can be performed in extremely small reaction volumes, significantly improving screening throughput and efficiency. Our MSP technology is based on fluorescence or absorbance detection and enables quantitative analysis of target products to ensure accuracy and sensitivity of screening. In addition, we also use automated processing systems to further standardize processes and improve processing capabilities.

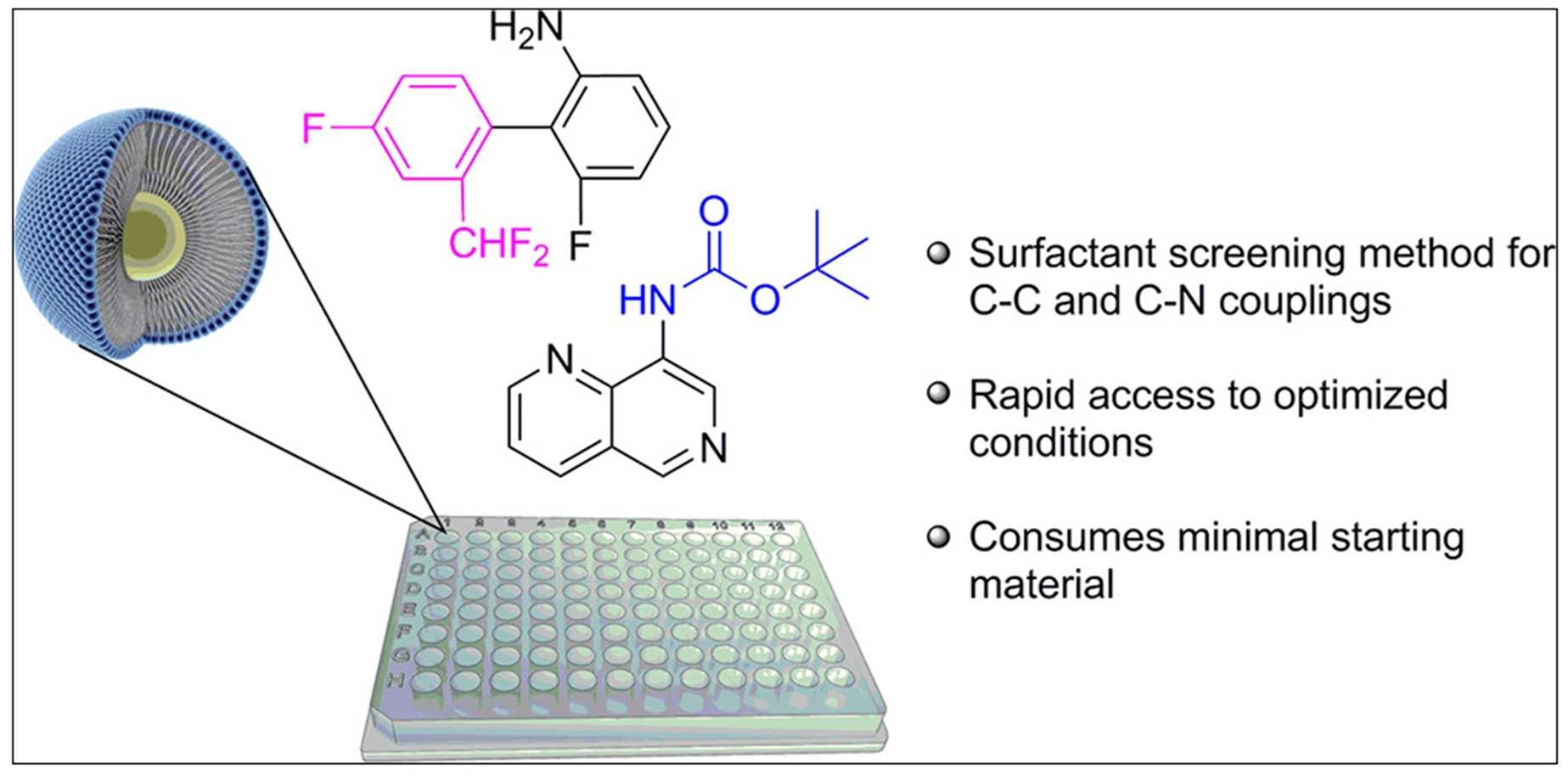

Microtiter plate reaction screening and optimization of surfactant chemistry. (Brocklehurst C E, et al., 2018)

Microtiter plate reaction screening and optimization of surfactant chemistry. (Brocklehurst C E, et al., 2018)

This technology is not only suitable for microbial cultivation, but also for various applications such as enzyme activity and metabolite screening.

Our team has rich experience and continues to combine professional knowledge and innovative thinking to provide customized solutions to customers.

Microtiter Plate Screening (MSP) technology is a high-throughput screening method that is widely used in microbial culture, enzyme activity detection, and metabolite screening. Microtiter Plate Screening technology plays an important role in modern biological science research due to its high throughput, low cost, quantitative analysis and wide applicability.

High throughput screening

MSP can screen thousands of samples in an instant and can be used to screen large mutant or compound libraries.

Highly Automated

MSP software facilitates automated sample addition and reading that eliminates the need for human intervention and optimizes experiment repeatability.

Precise quantitative analysis

MSP allows precise quantitative analysis by measuring changes in absorbance or fluorescence caused by the substrates/target products on the microplate.

Easy to operate

MSP technology operates fairly intuitively, is suitable for lab daily applications, and can be programmed to minimize human error.

High sensitivity

MSP technology detects target molecules at extremely low concentrations and works well in high sensitivity experiments.

Wide application range

MSP technology can be applied to screen various types of biomolecules and compounds such as enzymes, antibodies, small molecules, drugs, etc.

Strong data processing and analysis capabilities

The data generated by MSP technology can be efficiently processed and analysed by appropriate software, resulting in a fast and effective experimental output.

Cost-effectiveness

MSP technology typically costs less than standard experimental techniques as the amount of reagents is minimal and the time spent in the experiment is short.

Microtiter Plate Screening technology is widely applied because of its high efficiency and precision and is considered one of the key devices in contemporary biological science research and manufacturing. MSP technology has a wide range of application areas, including but not limited to the following aspects:

Screening of enzyme and metabolite mutant libraries

MSP techniques can be used to examine changes in enzyme activity or metabolites. Target products are quantitatively quantified by measuring fluorescence or absorbance changes, making screening accurate and sensitive.

Microbial culture and screening

MSP technology can be applied to the culture and screening of microorganisms, including studying cell heterogeneity, detecting mutants, and growing adherent cells or microbial biofilms. It can also be used to screen microorganisms for bioremediation and biotransformation capabilities.

MSP technology is used to screened and optimize biocatalysts (e.g., improvements in [FeFe] hydrogenases) with potential use in the renewable energy sector.

Immunoassays and clinical analysis

MSP is also widely applied in immunoassays, such as enzyme-linked immunosorbent assays (ELISA) to measure antibodies or antigens in blood.

MSP technology is employed to tailor microbial growth regimes and metabolisms in bioprocess development, including optimizing the fermentation phase by measuring biomass, pH and dissolved oxygen.

A list of frequently asked questions and answers about Microtiter Plate Screening technology:

Q: What is Microtiter Plate Screening (MSP)?

A: Microtiter Plate Screening (MSP) is a high-throughput microplate-based screening technology. By reacting the microplates and reading them with a reader, it allows you to screen and analyze hundreds of samples in quick time.

Q: What are the key benefits of MSP?

A: The main benefits of MSP technologies are:

Q: Where is MSP technology applied?

A: MSP technology is used for a wide variety of applications, not just for these:

Q: How does MSP technology work?

A: This is how MSP technology generally works:

Q: What are the drawbacks of MSP technology?

A: While MSP technology is effective, it is not without its limitations:

Q: How to maximize the screening potential of MSP technology?

A: Tips on how to make MSP technology screening more efficient include:

Q: What's the difference between MSP and other screening technologies?

A: In comparison with other screening technologies, MSP has increased throughput and automation. Plate screening, for instance, is simple but not efficient; MSP technology enables rapid and efficient screening through automated machines.

Please take a moment to fill out the form.

CD Biosynsis

Copyright © 2025 CD Biosynsis. All rights reserved.