Did you know that “tiny” cells are also ‘factories’?

Nowadays, biosynthesis technology with the concept of “green and sustainable development” is playing an increasingly important role. However, the protagonists of this clean revolution are not the factories with tall chimneys, but the micron-sized microorganisms (most of them), known as “cell factories”.

Q1 So, how do cell factories work?

As we all know, the production process of the factory is simply to process the raw materials and output the products. The same goes for cell factories.

1. Production line

In a cell factory, enzymes are like factory workers, processing substrates; Different enzymes work together to form a “production line” for metabolic synthesis and produce the products people want.

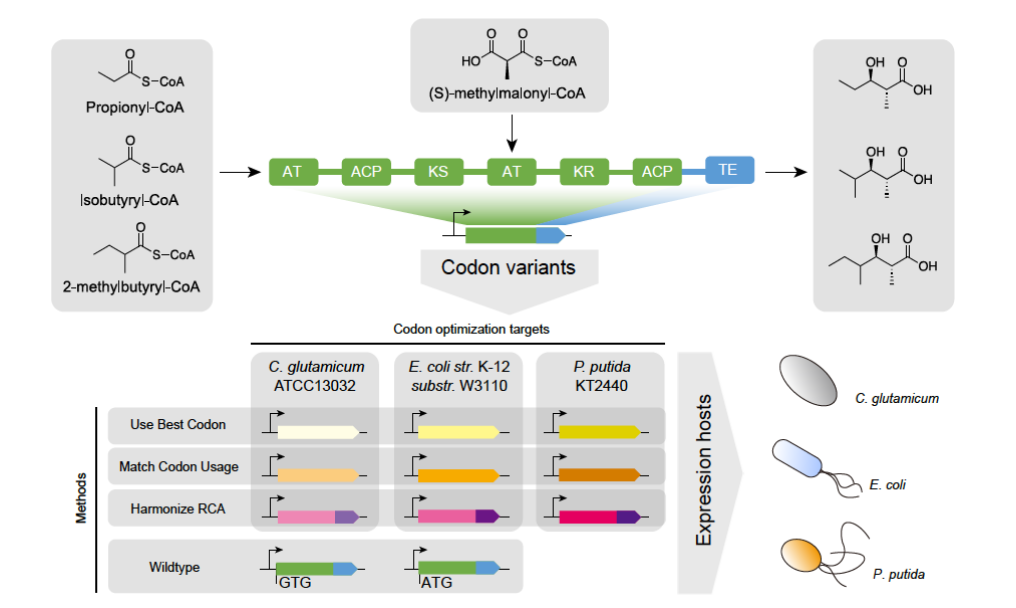

Fig.1 Cell factory “production line” composed of various enzyme workers

2. Production links

Therefore, the metabolic process of a cell can be regarded as three parts: input, synthesis and output, which is the basis on which the cell can be used as a factory for production.

Figure 2 The production process of the cell factory

Figure 2 The production process of the cell factory

3. Turn trash into treasure

Compared with the factory, the input raw materials of the cell factory are more “bells and whistles”. As the “big stomach king” of “meat and vegetarian taboo”, the “taste” of the cell is diverse, and there are traditional sugar-eating ones; There are those who eat plastic and other garbage; There are …… that work with sunlight The abundant source of raw materials makes the cell factory have a wide range of applications, and “turning waste into treasure” is one of its outstanding features.

Figure 3 Carbon source as raw material Source|Zhihu You can understand it in one second

4. Enzymes that work efficiently

Now that you’ve “eaten and drunk enough”, it’s time to get to work. The operation of the cell factory is inseparable from the “conscientious” workers such as enzymes. It reduces the activation energy required for the reaction, making the reaction more efficient, in other words, the presence of enzymes increases the efficiency of the cell factory.

Fig.4 Comparison of activation energy required for the reaction

5. The diffuse state of the cell factory

However, the inside of the cell factory is not as obsessive-compulsive friendly as the real factory, and enzyme workers often have to run around the factory for a long time before they encounter the substrate it processes. In addition, the complex metabolic background is also one of the limiting factors for the output of cell factories. In fact, the cell factory is a “compound” factory, which leads to the phenomenon of “mistrack”: intermediate products that should go to the next process are taken by other enzyme workers and processed unexpectedly, reducing the final yield.

Fig.5 Enzymes in the cell factory are in a diffuse state

6. Solution: Metabolic engineering

So what should you do when you encounter such a situation?

Don’t worry, we have a very useful tool – metabolic engineering, which can “open up sources and reduce expenditures”, meet the needs of biosynthesis “heavenly creation”, and pull the track in the direction that is most beneficial to us by enhancing the required pathways and removing or weakening the competitive pathways.

Figure 6 Metabolic engineering can pull the track in the direction that is most beneficial to us

7. Diverse products of cell factories

Eventually, after a series of processes, colorful substances are presented in front of our eyes. From the daily life of food fermentation to the scientific research journey of drug development, cell factories are quietly contributing. With the development of science and technology and the in-depth study of the microscopic world, human beings are able to control the type and output of output substances by regulating input and internal metabolism, expanding the scope of application of cell factories.

Figure 7 Products of cell factories: antibiotics

Q2 What are the “outstanding representatives” of cell factories?

People’s daily life revolves around “clothing, food, housing and transportation”, in which the cell factory has some amazing performance.

1. Clothing

“Love doesn’t come when you’re shining, but when you’re embarrassed.” Hermès’ pun slogan resonated with a lot. As a well-known luxury brand, its bags are widely known. However, there are many processes for leather products, and the use of chemical materials is complicated, and the problem of “three pollutions” is serious. In recent years, Hermès has launched a handbag made of mycelium fabric, which is actually cellulose produced by fungi and yeast cell factories, with good strength, durability and good hand feel, making it an alternative to animal leather.

Figure 9 Mycelium fabric handbag Source

2. Food

People take food as their day, and the satiety produced by carbohydrates can make people feel happy. “Crying Deep-Fried Food Trio for the Kid Next Door”: Starch, eggs, breadcrumbs are the secret to keeping it crispy. Have you ever imagined that you don’t have to face the loess with your back to the sky and work hard, but instead pour carbon dioxide and hydrogen into one jar after another, and starch can be produced continuously.

Sounds fanciful, right? But in fact, in 2021, plant-free synthesis from carbon dioxide to starch is no longer a “castle in the sky”. Under the condition of sufficient energy supply, theoretically, the annual starch output of a cell factory reactor with a size of 1 cubic meter is equivalent to the average annual starch yield of corn planting on 5 acres of land.

Fig.9 Module of starch cell factory

3. Shelter

Can you build a tower in a week? Are you kidding?

Hey, don’t say it, there really is. The Hy-Fi Tower, built in 2014, is a prime example. The entire tower is made up of corn, straw residue and mycelium. When a fungal factory is implanted into the right mold and provided in the right environment, the mycelium acts like glue to bond the residue together to form a material similar to Styrofoam. In less than a week, the mycelium bricks form a 12-metre-high tower that can be produced and sold in-house, and when the building is no longer useful, the bricks can be dismantled and transported to a fertilizer plant for composting.

Fig.10 Hy-Fi Tower

4. Transportation

Oil is a non-renewable resource with limited reserves, and sooner or later it will be depleted. Biodiesel is a sustainable way to meet the world’s growing demand for transportation fuels. In the Etuoke Banner Industrial Park in Ordos City, Inner Mongolia, the largest microalgae carbon sequestration demonstration project in China has been built, which can fix 10,000 tons of carbon dioxide per year and have an economic output value of more than 200 million yuan. The microalgae cell factory “eats” carbon dioxide and produces oil, which is a good helper for carbon sequestration and emission reduction. Therefore, the microalgae cell factory can also be linked with coal chemical enterprises to turn waste into treasure – the “full and full” microalgae are transformed into algae powder, which can be used for health care, cosmetics and other aspects to form an industrial chain.

Q3 Where are the prominence of cell factories compared to chemical synthesis?

Turning waste into treasure, energy saving and environmental protection, carbon sequestration and emission reduction are certainly beyond the reach of chemical synthesis. “Clean” aside, chemical synthesis can only match the synthesis power of natural products.

1. Natural products with diverse structures

Natural products tend to have multiple stereocenters. Take, for example, soft spongy B, which stands at the top of the pyramid of complexity in chemical total synthesis, has 32 solid centers, implying the presence of up to 4 billion isomers. In this vast ocean of isomers, only one has anti-cancer activity, and it is no less difficult to synthesize the only “solution” than looking for a needle in a haystack. Even its intermediate, eribulin, has 16,384 isomers.

Fig.12 Structure of soft spongiferin B with anticancer activity Source

2. Simplify the complex cell factory

In the cell factory, the complex synthesis process becomes very “simple”, as long as the biosynthesis gene is clarified, the synthesis pathway is introduced into the appropriate cell factory, and the raw materials are provided, you can sit back and enjoy the results. In other words, if you want to get a certain product, you can find workers who can process it and a factory with the appropriate facilities, pay the money, and wait for the delivery date to come. As for whether the worker is processing along the way or the other way around, you don’t have to care about these details at all.

Fig.13 Schematic diagram of the synthesis of vinblastine in a cell factory