Metabolic engineering refers to the purposeful modification and modification of cellular metabolic pathways using genetic engineering techniques, altering cellular characteristics, and producing specific target products.

Metabolic engineering has a history of 30 years since its development. From traditional modification techniques such as knocking out byproduct generation pathways, releasing product synthesis inhibition, and overexpressing key enzymes in synthesis pathways, new metabolic modification techniques have been developed, such as establishing metabolic reaction databases and network model calculations, assembling metabolic pathways, and dynamically regulating gene expression.

The main strain that cannot be ignored in the field of metabolic engineering is Escherichia coli. Escherichia coli has become an excellent industrial model microorganism due to its long research history, clear genetic background, fast anaerobic growth rate, ability to utilize simple inorganic salt culture media and multiple substrates (glucose, xylose, glycerol). Metabolic engineering modification of Escherichia coli can be used to produce various products such as organic alcohols, amino acids, organic acids, organic amines, vitamins, natural products, and polyhydroxyalkanoates (PHA). It is also applied in the green biosynthesis of bulk chemicals such as L-alanine, L-lysine, L-threonine, 1,3-propanediol, D-lactic acid, succinic acid, and pentanediamine. Based on the above advantages and its widespread use, Escherichia coli has become an important component in the field of metabolic engineering and has a very bright future.

Related Services

E. coli CRISPR-Cas9 genome editing

E.coli Metabolic Engineering Service

Protein expression in E. coli service

Next, let’s take Escherichia coli as an example to learn about the design and optimization of metabolic engineering pathways in Escherichia coli.

30 year development path of Escherichia coli metabolic engineering

Design of metabolic pathways in Escherichia coli

Escherichia coli metabolic engineering technology

The designed metabolic pathways of Escherichia coli can be divided into three types based on their sources:

(1) Using only the metabolic pathway of Escherichia coli itself:

The synthetic pathways of metabolites such as succinic acid, pyruvate, L-threonine, L-valine, etc. already exist in the natural metabolic pathways of Escherichia coli. Proper modification and regulation of the metabolic pathway of Escherichia coli itself, such as releasing feedback inhibition of key sites, increasing the expression of rate limiting enzymes, regulating cofactor metabolic balance, etc., will maximize the metabolic flow towards the target product.

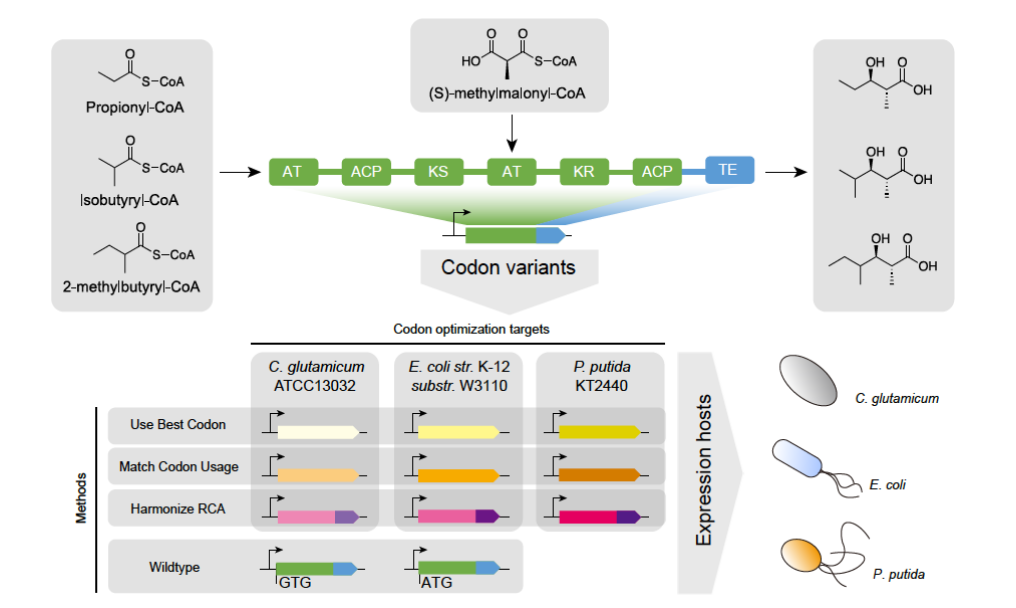

(2) Introducing exogenous metabolic pathways:

Escherichia coli itself has limited genes and often requires the use of exogenous genes to supplement or improve the efficiency of its original metabolic pathways. For example, in the production of 1,3-propanediol in Escherichia coli cell factories, glycerol-3-phosphate dehydrogenase and glycerol-3-phosphatase from brewing yeast, as well as glycerol dehydratase from Klebsiella pneumoniae, were introduced; Introduced alanine dehydrogenase from Geobacillus stearothermophilus in the L-alanine cell factory; In the 1,4-butanediol Escherichia coli cell factory, five exogenous genes from different sources were integrated.

(3) Creating metabolic pathways that do not exist in nature:

With the support of rational protein modification and de novo design techniques, the design of metabolic pathways has also broken through the limitations of natural pathways and gradually developed non natural synthetic pathways.

Creation and optimization of synthetic pathways for Escherichia coli

DNA Fragment Assembly Technology

DNA fragment assembly technology is an important prerequisite for achieving the creation of E. coli pathways. Traditional DNA fragment assembly mainly relies on restriction endonucleases and DNA ligases, but this assembly method has certain limitations, such as leaving “scars” at the junction, and there cannot be corresponding cleavage sites inside the gene fragments to be assembled, reducing the range of selectable endonucleases.

(1) Golden Gate assembly technology:

IIS type restriction endonucleases (Restriction endonuclease Type II) are required, which have the ability to recognize and cleave double stranded DNA with inconsistent positions. This characteristic allows it to cleave DNA outside the recognition site, and the resulting sticky ends are sequentially connected by ligases to assemble DNA fragments without cleavage sites, achieving seamless connection of multiple fragments.

(2) Gibson assembly technology:

No restriction endonucleases are required, but each DNA fragment contains homologous sequences of 15-20 bp on each end. Based on this, assembly is carried out in the order of homologous sequences. Assembly involves the collaborative participation of multiple enzymes. DNA 5 ‘Exonuclease first cleaves a sticky end, and each sticky end complements each other based on homologous relationships. Then, DNA polymerase replicates and synthesizes the missing base, and finally, DNA ligase connects the sticky end. This method can quickly, efficiently, and accurately insert one or more DNA fragments into a linearized vector in a predetermined direction, achieving seamless assembly.

(3) CPEC technology:

CPEC (Circular polymerase extension cloning) is the abbreviation for circular polymerase extension cloning. Its requirements for DNA fragments are similar to Gibson, with homologous sequences at each end. CPEC is a technology for assembling DNA fragments through PCR: DNA fragments and carriers undergo denaturation and unwinding, and end homologous sequences complement each other during annealing. The sequences serve as templates and primers for each other, and are extended into circular DNA molecules containing gaps under the action of DNA polymerase. This gap can be repaired in Escherichia coli to obtain a complete plasmid. Overall, CPEC is a simpler, more efficient, and economical DNA assembly technique with a wider range of applications, but it is not suitable for the assembly of high GC content DNA fragments.

| Catalog Number | Product Name | Product Size | Applications | Price |

|---|---|---|---|---|

| GE0001L | Cas9-NLS | 400 pmol | Random Mutagenesis | Online Inquiry |

| GE0001X | Cas9-NLS | 2,000 pmol | Random Mutagenesis | Online Inquiry |

| GE0002S | CD® Cas12a | 70 pmol | Random Mutagenesis | Online Inquiry |

| GE0002X | CD® Cas12a | 2,000 pmol | Random Mutagenesis | Online Inquiry |

| GE0003S | CD® Cas9 Nickase | 70 pmol | Random Mutagenesis | Online Inquiry |

| GE0003L | CD® Cas9 Nickase | 400 pmol | Random Mutagenesis | Online Inquiry |

| GE0004S | CD® Cas9 Nuclease | 70 pmol | Random Mutagenesis | Online Inquiry |

| GE0004L | CD® Cas9 Nuclease | 400 pmol | Random Mutagenesis | Online Inquiry |

| GE0004X | CD® Cas9 Nuclease | 2,000 pmol | Random Mutagenesis | Online Inquiry |

| GE0005 | CRISPR Nuclease mRNA | 15 μg | Insertion of target sequence into the Cas9-sgRNA constructs. | Online Inquiry |

| GE0006 | gRNA Synthesis Kit | 20 Reactions | Random Mutagenesis | Online Inquiry |

| GE0007S | Monarch RNA Cleanup Kit | 10 Preps | Random Mutagenesis | Online Inquiry |

| GE0007L | Monarch RNA Cleanup Kit | 100 Preps | Random Mutagenesis | Online Inquiry |

| GE0008S | sgRNA Synthesis Kit | 10 Reactions | Random Mutagenesis | Online Inquiry |

| GE0008L | sgRNA Synthesis Kit | 20 Reactions | Random Mutagenesis | Online Inquiry |

| GE0009S | SNAP-tagged dCas9 | 70 pmol | Random Mutagenesis | Online Inquiry |

| GE0009L | SNAP-tagged dCas9 | 400 pmol | Random Mutagenesis | Online Inquiry |

| GE0010S | Staphylococcus aureus Cas9 | 70 pmol | Random Mutagenesis | Online Inquiry |

| GE0010L | Staphylococcus aureus Cas9 | 400 pmol | Random Mutagenesis | Online Inquiry |

Escherichia coli genome editing technology

Creating metabolic pathways on the genome and obtaining genetically stable Escherichia coli cannot be achieved without genome editing technology. Through gene editing, the insertion of exogenous genes, the knockout of endogenous genes, and the expression regulation of key genes can be achieved.

The homologous recombination system is the foundation of Escherichia coli genome editing technology. The most commonly used system in Escherichia coli is the Red homologous recombination system, which originates from the incoming phage and includes three proteins Exo, Beta, and Gam. With the synergy of these three proteins, homologous recombination of exogenous fragments is achieved. Its homologous recombination efficiency is high, the homologous arm can be as short as 50 bp, the operation is simple, and it is widely used in gene editing in Escherichia coli. Based on the Red homologous recombination system (specifically the principle of E. coli Red homologous recombination in previous articles on bacteria), combined with different strategies, researchers have developed non resistant genome editing techniques. The following three commonly used techniques are:

(1) Two step homologous recombination based on FIp recombinase:

Flp recombinase can recognize short flippase recognition site sequences and cleave sequences located between two flippase recognition targets (FRTs). By combining the Red homologous recombination system, the resistance genes with FRT sequences at both ends are integrated into the target site on the genome, and then the resistance genes are knocked out under the mediation of Flp recombinase. The disadvantage of this technology is that it leaves a segment of FRT sequence at the target site, which is not traceless editing and can affect the efficiency of gene editing after multiple rounds of editing.

(2) A two-step positive and negative screening method based on the sacB gene:

The sacB gene encodes a secreted sugarcane candy polysaccharide enzyme, which can catalyze the hydrolysis of sucrose into glucose and fructose, and synthesize fructose into high molecular weight fructose. It has a lethal effect on Escherichia coli and is a negative screening marker. Under the mediation of the Red homologous recombination system, fragments containing resistance genes and sacB genes are first integrated into the target site, and then the target fragment is integrated into the target site. The gene fragments containing resistance genes and sacB genes are replaced and cultured in a medium containing sucrose. Through reverse screening strategy, the correct transformants that replace the resistance genes and sacB gene fragments are obtained.

(3) One step homologous recombination based on CRISPR/Cas9:

Cas9 protein undergoes splicing at the target site mediated by gRNA, causing double stranded breaks in the Escherichia coli genome and resulting in lethal effects. The Red homologous recombination system can integrate donor fragments into the target site, repair broken DNA double strands, or undergo homologous recombination before Cas9 protein cleavage, causing Cas9 to lose the target site without cleavage.

Gene expression regulation technology

Gene expression regulation is an important means of optimizing metabolic pathways and the core of metabolic engineering modification. After creating pathways in Escherichia coli, it is necessary to regulate the expression intensity of genes at key nodes, including enhancing product synthesis pathways and cofactor synthesis pathways, or weakening some genes that may cause bacterial growth but have adverse effects on product production after knockout. According to the technical level, it can be divided into single gene regulation, multi gene regulation, and gene dynamic regulation techniques.

(1) Single gene regulation:

Single gene regulation is the regulation of the expression of a specific gene in a metabolic pathway on chromosomes. In the early stages of metabolic engineering, strong promoters were commonly used for single gene regulation, such as the IPTG inducible Tac promoter, T7 promoter, etc. However, for metabolic pathways, strong expression of a single gene may not be the optimal approach, leading to metabolic burden. To achieve optimal expression of a single gene, Lu et al. constructed a promoter library in Escherichia coli and obtained promoters of different intensities for the regulation of glucose transporter gene galP and glucose kinase gene glk. The combined regulation of strain GalP93-GIk37 significantly increased glucose consumption rate. In addition to the promoter library, using RBS library to regulate succinic acid transporter proteins DcuB and DcuC single genes can also improve the ability and yield of succinic acid transport to the extracellular environment.

(2) Multi gene regulation:

Single gene regulation can only operate on the single gene dimension, and even combined regulation greatly reduces the capacity of its library, making it difficult to screen the optimal combination of multiple genes. In the optimization of metabolic pathways, the efficient production of target chemicals often requires the synergistic expression of multiple genes to achieve the optimization of metabolic pathways. The Keasling team has developed a Tunable Intergene Regions (TIGRs) library technology. This technology is based on the principle that gene sequence changes can affect gene expression intensity, achieving the goal of simultaneously regulating the expression intensity of multiple genes within a single operon. By using this technology, multiple genes involved in the mevalonate pathway in Escherichia coli were co expressed, resulting in a 7-fold increase in mevalonate production. Isaacs et al. developed the Multiple Automated Genome Engineering (MAGE) technology, which utilizes the Red homologous recombination system and automated loop equipment to perform loop editing on multiple gene loci, improving gene editing efficiency. Based on CRISPR/Cas9 technology, three gene libraries of xylose metabolism pathways were regulated on chromosomes, and the optimal strains were screened, resulting in a 3-fold increase in xylose metabolism rate.

(3) Gene dynamic regulation:

Dynamic regulation is one of the most effective strategies in optimizing metabolic pathways. Although static regulation such as single gene and multi gene regulation is easy to operate and has significant effects, intracellular metabolites are dynamic. If the expression level of related genes is too high, it will waste cell resources, and if the expression level is too low, it will limit metabolic pathways. The yield and yield of the final target product are difficult to improve due to the imbalance of cellular metabolism. In order to timely balance the relationship between gene expression required for product synthesis and global metabolic levels, the introduction of gene dynamic regulation can respond to metabolic signals in real time and provide timely feedback regulation to adapt to changes in cellular metabolism and environment.

Summary

Due to its clear genetic background, abundant metabolic element library, and complete genome editing technology, Escherichia coli has become one of the most suitable chassis strains for metabolic engineering modification experiments. In recent years, Escherichia coli has made a series of new progress in CO2 fixation and methanol utilization. After metabolic engineering modification, Escherichia coli can even grow using methanol as the sole carbon source, making outstanding contributions to carbon recycling. With the development of artificial intelligence and engineering rational design, combined with increasingly advanced biotechnology, Escherichia coli metabolic engineering will achieve a revolution of rationalization, engineering, and intelligence.

Reference: